22

EN

luBriCation

> Before lubricating the

machine, always first disconnect

the power plug.

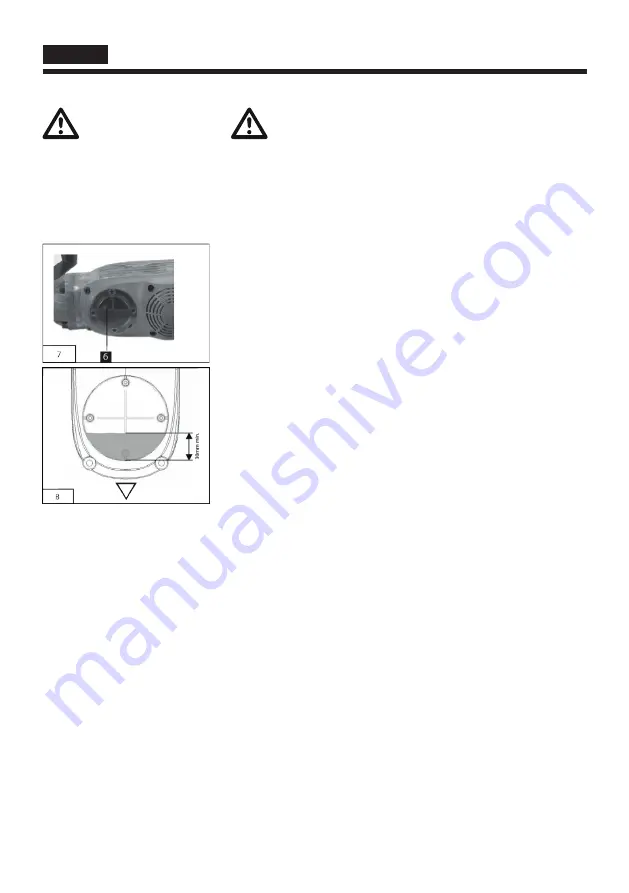

The demolition hammer has an

integrated oil tank. Before use,

check that the oil level is correct

(FiG. 7 and 8).

1. Keep the machine upright

with the toolholder face down

on the ground. If the level of oil

visible through the indicator is less

than 30 mm, fill the tank.

2. Use a cross head screwdriver

(not supplied) to unscrew the

access cover.

Be careful not to lose the rubber

gasket access cover.

3. Check the oil level before each

use to ensure that the machine is

properly lubricated during the work.

4. After filling, securely tighten

the indicator access cover.

5. Use oil - 15W40.

MaintenanCe

> ATTENTION

For any maintenance on the

machine, it is compulsory

to disconnect the power plug.

Machine inspection

The use of an used or blunted chisel

can cause malfunction of the engine

and reduce the efficiency.

Sharpen the chisels or replace them

if they are used.

Regularly inspect the screws

and make sure they are properly

tightened. If a screw is loosened,

tighten it immediately.

Failure to observe this information

may present a risk of serious injury.

replacing carbon brushes

If brushes are worn, cracked

or if the length is less than 6 mm,

replace them with original brushes.

Always replace the brushes in pairs.

To access the brushes, remove

its covers (on each side of the

engine block).

oil level checking

The breaker oil level should be

checked regularly for better

functioning (see the section

“Lubrication”).

oil change

The oil should be replaced after

approx. 40-50 hours of use.

Unscrew the access cover (6)

with a cross head screwdriver

(not supplied) and drain the oil.

So that the oil does not flow

uncontrollably, hold one funnel

below and collect the oil in a

container until it has passed

through.

note: used oil is a major

source of pollution of our

environment, so it is highly

recommended to bring it in an

airtight container at a service

station or a waste sorting unit.

do not throw away the oil with

domestic waste, do not lie on

the ground, in sewers or in

rainwater pipes.

Fill the reservoir (approx.

70-80 ml) of oil through the filling

opening (6).

The oil level should reach the

required level. Firmly retighten the

access cover.

After a brief period of use,

the oil level should be checked

again.

Cleaning certain parts

When the breaker has been used

for some time, dust or other

substances can prevent proper

operation of the device.

You can then clean and lubricate

the device.

Frequently check your device.

Pay attention to any problem that

might occur with the power cord,

plug, switch...

The engine is the main element

of the hammer. It is important that

it is not damaged, and that is free

of grease and moisture.

After each use, use compressed

air to blow the dust from vents

(wear safety glasses for this

operation).

Spare parts

Defective parts must be replaced

with original spare parts by an

authorized company.

StoraGe

1. Always store your hammer

in a dry place and out of reach

of children.

2. Always keep the breaker

in a horizontal position.

3. Keep air vents clean and free

from debris. If necessary,

use compressed air to blow the dust

accumulated into the slots (to do

this, use safety glasses).

4. Keep the housing clean and

grease-free. Never use water,