40

EN

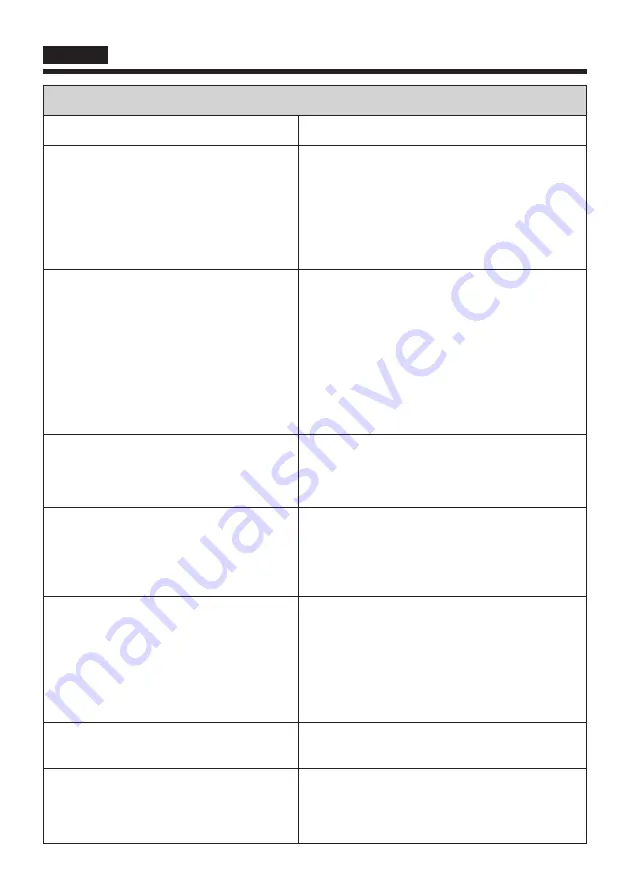

FAQS / TROUBLESHOOTING

Question/Problem

Solution

The engine doesn’t start or runs too slow:

• No power voltage;

• Too low power voltage;

• Too low temperature;

• Failure in the pressure switch;

• Failure in the engine;

• Check the power cable, connecting plug, socket and circuit

breaker;

• Avoid long extension cords;

Use an extension cord with enough transversal section;

• Do not use the compressor with an exterior temperature

lower than +5°C;

• Repair or replace;

• Repair or replace;

The compressor works but doesn’t have

enough pressure or has a low discharge

capacity:

• The air filter is clogged;

• Leak in the non-return or safety valve;

• Leak in the compressed air pipes;

• Damaged joints;

• Leak in the condensed water purging screw;

• Damaged cylinder and segments;

• Clean or replace;

• Check and repair the valves;

• Check or repair;

• Replace the damaged joints;

• Tighten the screw manually;

Check the screw’s joint and, if necessary, replace it;

• Repair or replace;

The engine stops abruptly:

• Damaged moving parts due to low oil level in the

compression pump;

• Damaged or blocked moving parts;

• Check the moving parts status and replace them if

necessary;

• Repair or replace the damaged parts;

The compressor stops and thermal

protection triggers:

• Engine overheat;

• Rotating parts are blocked or damaged, provoking

the overheat;

• Allow the compressor to cool down, press the thermal

protection trigger button and switch the compressor on;

• Unclog or replace the parts, press the thermal protection

trigger button and turn the compressor back on;

The compressor is running, the pressure is

shown in the manometer but the tools aren’t

responding:

• Leak in the compressed air hose;

• Leaks in the quick joints;

• The pressure defined in the regulator is too low;

• Check the compressed air hose and tools. Replace them if

necessary;

• Check the quick joint and replace it if necessary;

• Increase the pressure using the pressure regulator;

Too much oil consumption:

• The oil level is too high;

• Damaged cylinder or segment;

• Check and adjust the oil level;

• Repair or replace;

Abnormal noise or vibration:

• Loosen parts or connecting accessories;

• Strange elements inside the engine;

• Damaged joints;

• Damaged moving parts;

• Check and tighten;

• Check and clean;

• Replace the damaged joints;

• Repair or replace;

Summary of Contents for PRO-POWER VICOC200A

Page 4: ...4 1 Fig E Fig D Fig F 2 7 3 4 6 1 3 4 1 2 2...

Page 5: ...5 Fig G Fig H Fig I Fig J Fig K 16 28 STOP 1 1 3 4 6 1 2...

Page 6: ...6 Fig M Fig L 2 3 4 1 2 4...

Page 54: ...54...

Page 55: ...55...

Page 56: ...RUA DA G NDARA 664 4520 606 S JO O DE VER STA MARIA DA FEIRA PORTUGAL MI_VICOC200A_REV01_AGO18...