Moster 185 Factory R - Maintenance manual - V1

21

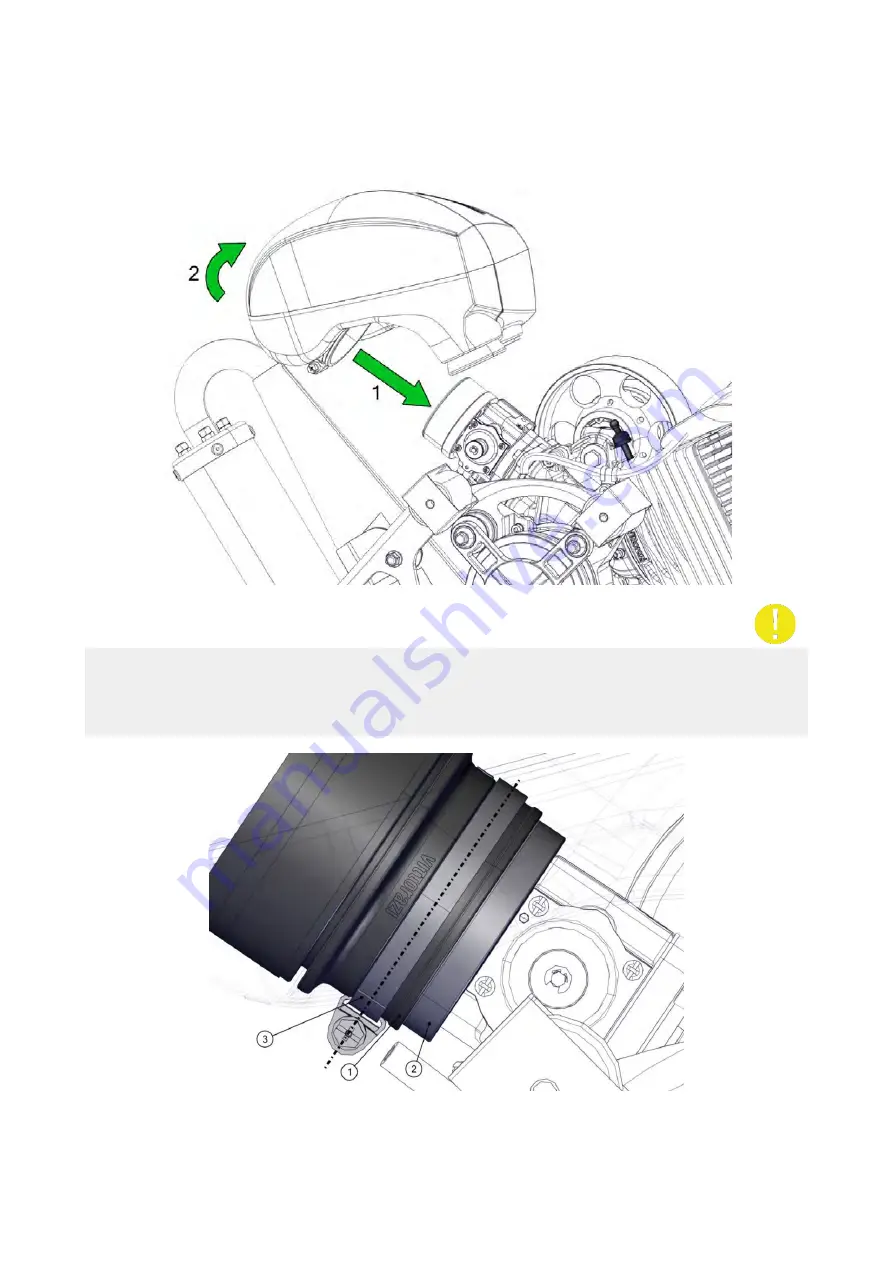

3.3.3 Airbox assembly

Insert the sleeve into the airbox. Insert the Snaplock

Connect the sleeve of the airbox to the carburettor (1), after having inserted it rotate the airbox to

fix the Snaplock (2).

The airbox sleeve (1) must be completely inserted into the Airbox connector (2), the fixing

clamp (3) correctly inserted on the seat and aligned as in the figure.

Summary of Contents for Moster 185 Factory R

Page 1: ...MOSTER 185 FACTORY R Maintenance manual release V1 2022 valid for MY20 MY22 versions...

Page 2: ...Moster 185 Factory R Maintenance manual V1 2...

Page 5: ...Moster 185 Factory R Maintenance manual V1 5...

Page 73: ...Moster 185 Factory R Maintenance manual V1 73...

Page 124: ...Moster 185 Factory R Maintenance manual V1 124...

Page 125: ...Moster 185 Factory R Maintenance manual V1 125...