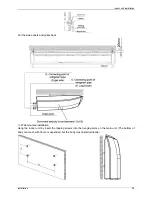

Drainage pipe installation

112

Installation

6.3 Drainage test

6.3.1 Water leakage test

After finishing the construction of drainage pipe system, fill the pipe with water and keep it for 24 hours to

check whether there is leakage at joint section.

6.3.2 Water discharge test

1. Natural drainage mode(the indoor unit with outdoor drainage pump)

Infuse above 600ml water through water test hole slowly into the water collector, observe whether the

water can discharge through the transparent hard pipe at drainage outlet.

2. Pump drainage mode

2.1 Disconnect the plug of water level switch, remove the cover of water test hole and slowly infuse about

2000ml water through the water test hole, be sure that the water will not touch the motor of drainage

pump.

2.2 Power on and let the air conditioner operate for cooling. Check operation status of drainage pump, and

then connect the plug of water level switch, check the operation sound of water pump and observe

whether the water can discharge through the transparent hard pipe at drainage outlet. (In light of the

length of drainage pipe, water shall be discharged about 1 minute delayed)

2.3 Stop the operation of air conditioner, power off the power supply and put the cover of water test hole

back to the original place.

a. After stopped the air conditioner 3 minutes, check whether there is anything abnormal. If drainage pipes

have not been distributed properly, over back-flow water shall cause the flashing of alarm indicator at

remote-controlled receiving board and even water shall run over the water collector.

b. Continuously infusing water until water level alarmed, check whether the drainage pump could

discharge water at once. If water level does not decline under warning water level 3 minutes later, it

shall cause shutdown of unit. When this situation happens, the normal startup only can be recovered by

turning down power supply and eliminating accumulated water.

Note:

Drain plug at the main water-containing plate is used for eliminating accumulated water in

water-containing plate when maintaining air conditioner fault. During normal operation, the plug shall be

filled in to prevent leakage.

6.4 Insulation work of drainage pipe

Refer the introduction to the insulation engineering parts.

Summary of Contents for ACP-12CC35AECI

Page 2: ......

Page 4: ......

Page 15: ...Service Space 12 Indoor Units 3 Service Space 1000mm 1000mm 1000mm 1000m m ...

Page 18: ...Air Velocity Distributions Reference Data Indoor Units 15 30 42K Cooling Heating ...

Page 19: ...Air Velocity Distributions Reference Data 16 Indoor Units 48 55K Cooling Heating ...

Page 24: ...Field Wiring Indoor Units 21 10 Field Wiring ...

Page 31: ...Wiring Diagrams 28 Indoor Units 4 Wiring Diagrams MTBU 12HWFN1 QRD0W MTB 18HWFN1 QRD0 ...

Page 33: ...Static Pressure 30 Indoor Units 5 Static Pressure MTBU 12HWFN1 QRD0W MTB 18HWFN1 QRD0 ...

Page 34: ...Static Pressure Indoor Units 31 MTB 24HWFN1 QRD0 MTB 30HWFN1 QRD0 ...

Page 44: ...Service Space Indoor Units 41 3 Service Space ...

Page 46: ...Wiring Diagrams Indoor Units 43 Pre setting Instructions ...

Page 55: ...52 Indoor Units 10 Field Wiring ...

Page 59: ...Service Space 56 Indoor Units 3 Service Space ...

Page 60: ...Wiring Diagrams Indoor Units 57 4 Wiring Diagrams ACP 12CC35AECI ACP 18CC50AECI ...

Page 64: ...Field Wiring Indoor Units 61 10 Field Wiring ACP 12CC35AECI ACP 18CC50AECI ...

Page 68: ...Dimensions Console Type 65 2 Dimensions 16 Drain pipe 195 Hanging arm Unit mm 700 600 210 ...

Page 69: ...Service Space 66 Console Type 3 Service Space ...

Page 70: ...Wiring Diagrams Console Type 67 4 Wiring Diagrams MFAU 12HRFN1 QRD0W ...

Page 75: ...Field Wiring 72 Console Type 10 Field Wiring MFAU 12HRFN1 QRD0W ...

Page 81: ...Wiring Diagrams 78 Outdoor Units 4 Wiring Diagrams MOZU 12HFN1 QRD0W MOZU 18HFN1 QRD0 ...

Page 82: ...Wiring Diagrams Outdoor Units 79 MOFU 24HFN1 QRD0 MOYU 30HFN1 QRD0 ...

Page 83: ...Wiring Diagrams 80 Outdoor Units MOYU 36HFN1 QRD0 ...

Page 84: ...Wiring Diagrams Outdoor Units 81 MOYU 36HFN1 RRD0 MOYU 42HFN1 RRD0 ...

Page 85: ...Wiring Diagrams 82 Outdoor Units MOEU 48HFN1 QRD0 MOEU 48HFN1 R MOEU 55HFN1 RRD0RD0 ...

Page 111: ...Refrigerant pipe installation 108 Installation ...

Page 151: ...Troubleshooting 148 Electrical Control System 2 4 4 3 E3 malfunction ...

Page 155: ...Troubleshooting 152 Electrical Control System 2 4 4 8 P1 malfunction For 36k models ...

Page 161: ...Troubleshooting 158 Electrical Control System 2 4 4 14 P7 malfunction ...

Page 174: ...www VIVAX com ...