Electric Characteristics

Indoor Units

59

6. Electric Characteristics

Model

Indoor Units

Power Supply

Hz

Voltage

Min.

Max.

MFA

ACP-12CC35AECI

50

220-240

198

254

20

ACP-18CC50AECI

50

220-240

198

254

20

Note:

MFA: Max. Fuse Amps. (A)

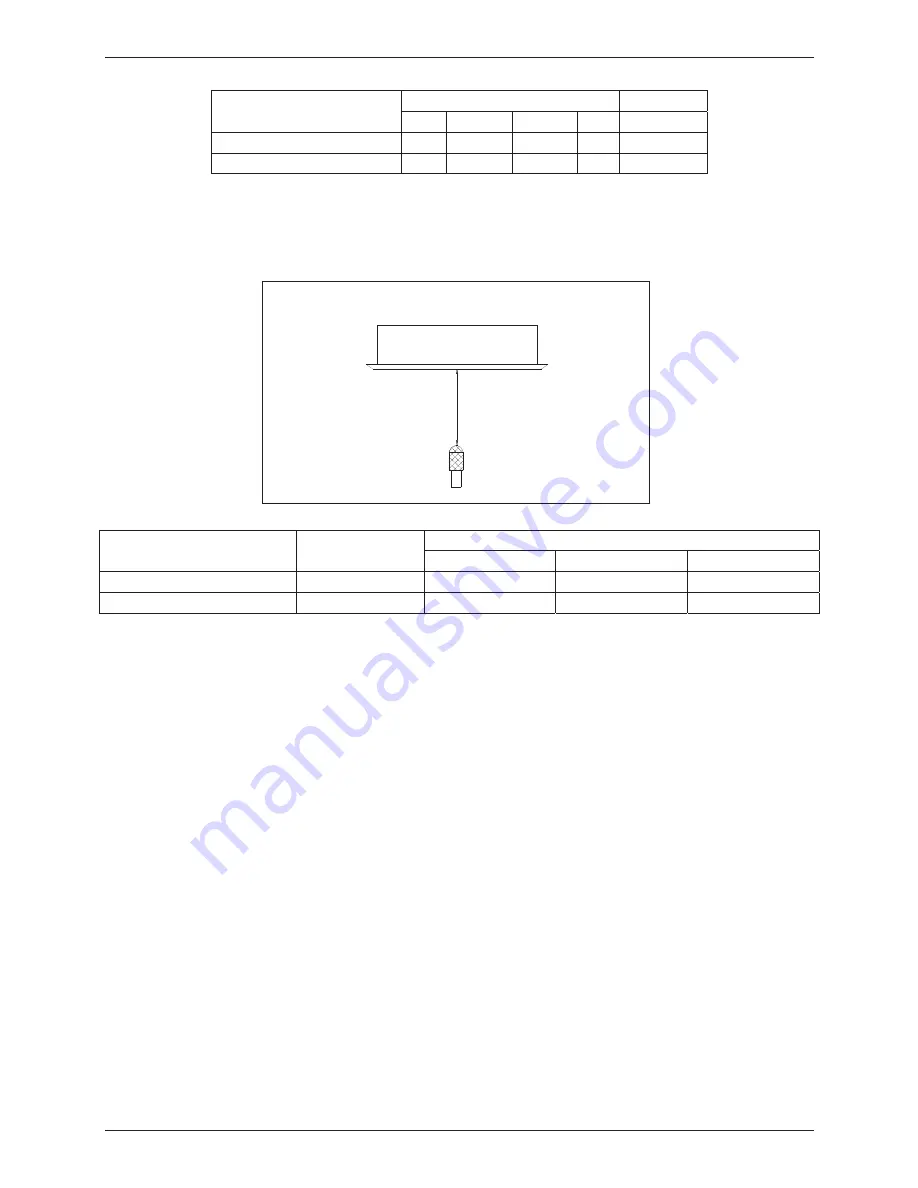

7. Sound Levels

1.4m

Microphone

Model

Noise Power dB(A)

Noise level dB(A)

H

M

L

ACP-12CC35AECI

54

45

42

39

ACP-18CC50AECI

59

48

40

33

Summary of Contents for ACP-12CC35AECI

Page 2: ......

Page 4: ......

Page 15: ...Service Space 12 Indoor Units 3 Service Space 1000mm 1000mm 1000mm 1000m m ...

Page 18: ...Air Velocity Distributions Reference Data Indoor Units 15 30 42K Cooling Heating ...

Page 19: ...Air Velocity Distributions Reference Data 16 Indoor Units 48 55K Cooling Heating ...

Page 24: ...Field Wiring Indoor Units 21 10 Field Wiring ...

Page 31: ...Wiring Diagrams 28 Indoor Units 4 Wiring Diagrams MTBU 12HWFN1 QRD0W MTB 18HWFN1 QRD0 ...

Page 33: ...Static Pressure 30 Indoor Units 5 Static Pressure MTBU 12HWFN1 QRD0W MTB 18HWFN1 QRD0 ...

Page 34: ...Static Pressure Indoor Units 31 MTB 24HWFN1 QRD0 MTB 30HWFN1 QRD0 ...

Page 44: ...Service Space Indoor Units 41 3 Service Space ...

Page 46: ...Wiring Diagrams Indoor Units 43 Pre setting Instructions ...

Page 55: ...52 Indoor Units 10 Field Wiring ...

Page 59: ...Service Space 56 Indoor Units 3 Service Space ...

Page 60: ...Wiring Diagrams Indoor Units 57 4 Wiring Diagrams ACP 12CC35AECI ACP 18CC50AECI ...

Page 64: ...Field Wiring Indoor Units 61 10 Field Wiring ACP 12CC35AECI ACP 18CC50AECI ...

Page 68: ...Dimensions Console Type 65 2 Dimensions 16 Drain pipe 195 Hanging arm Unit mm 700 600 210 ...

Page 69: ...Service Space 66 Console Type 3 Service Space ...

Page 70: ...Wiring Diagrams Console Type 67 4 Wiring Diagrams MFAU 12HRFN1 QRD0W ...

Page 75: ...Field Wiring 72 Console Type 10 Field Wiring MFAU 12HRFN1 QRD0W ...

Page 81: ...Wiring Diagrams 78 Outdoor Units 4 Wiring Diagrams MOZU 12HFN1 QRD0W MOZU 18HFN1 QRD0 ...

Page 82: ...Wiring Diagrams Outdoor Units 79 MOFU 24HFN1 QRD0 MOYU 30HFN1 QRD0 ...

Page 83: ...Wiring Diagrams 80 Outdoor Units MOYU 36HFN1 QRD0 ...

Page 84: ...Wiring Diagrams Outdoor Units 81 MOYU 36HFN1 RRD0 MOYU 42HFN1 RRD0 ...

Page 85: ...Wiring Diagrams 82 Outdoor Units MOEU 48HFN1 QRD0 MOEU 48HFN1 R MOEU 55HFN1 RRD0RD0 ...

Page 111: ...Refrigerant pipe installation 108 Installation ...

Page 151: ...Troubleshooting 148 Electrical Control System 2 4 4 3 E3 malfunction ...

Page 155: ...Troubleshooting 152 Electrical Control System 2 4 4 8 P1 malfunction For 36k models ...

Page 161: ...Troubleshooting 158 Electrical Control System 2 4 4 14 P7 malfunction ...

Page 174: ...www VIVAX com ...