OmniFlow 330

No.

Name

Description

1

Start button

Run the machine.

2

Test button

The paper will stop near the exit. It can be used to adjust the

connecting machines to the correct position.

3

Stop/Pause button

Stop the machine.

4

Clear button

Clear the input data or the warning message.

5

Confirm button

Confirm the input data.

6

Number button

Input data.

7

Page down button

Reserved button.

8

Page up button

Reserved button.

9

Mode button

Select different interfaces.

10

Backward button

When paper gets stuck inside, they can be used to drive the

paper out.

11

Forward button

When paper gets stuck inside, they can be used to drive the

paper out.

12

No sheets indicator

The indicator will be illumined without placing paper in long

run.

13

Error indicator

When machine comes up errors, the indicator will be

illumined.

14

Paper jam indicator

When sheets jam inside, the indicator will be

illumined.

15

Top cover indicator

When top cover opened, the indicator will be

illumined.

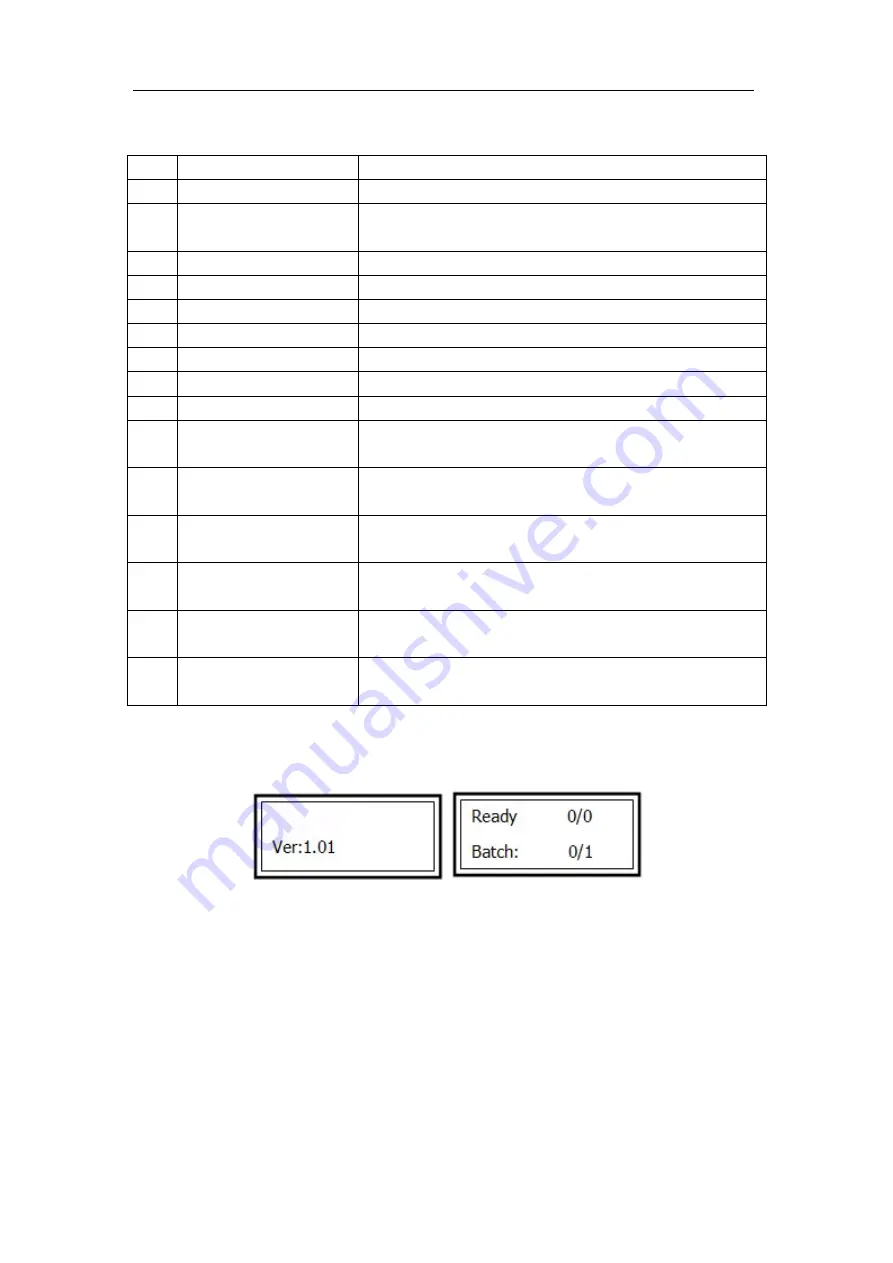

5.3 Standby

When power on the machine, it will come up the

Vivid

welcome interface. Then it

will enter standby interface. Ver

:

1.01 means the current software version of

machine is 1.03.As for the “Ready 0/0,the left 0 means quantity of the paper being

run and the right 0 means the preset quantity of paper. When the being run quantity

reach the preset quantity, the machine will stop automatically. In standby interface,

we can use number keys for quantity preset and “C” button to clear the quantity.

The largest input is 999.

Note

:

Only in standby interface can we press the green start button to run the

machine.

12