VXO4841DBF

INSTALLATION GUIDE

PAGE 4 of 5

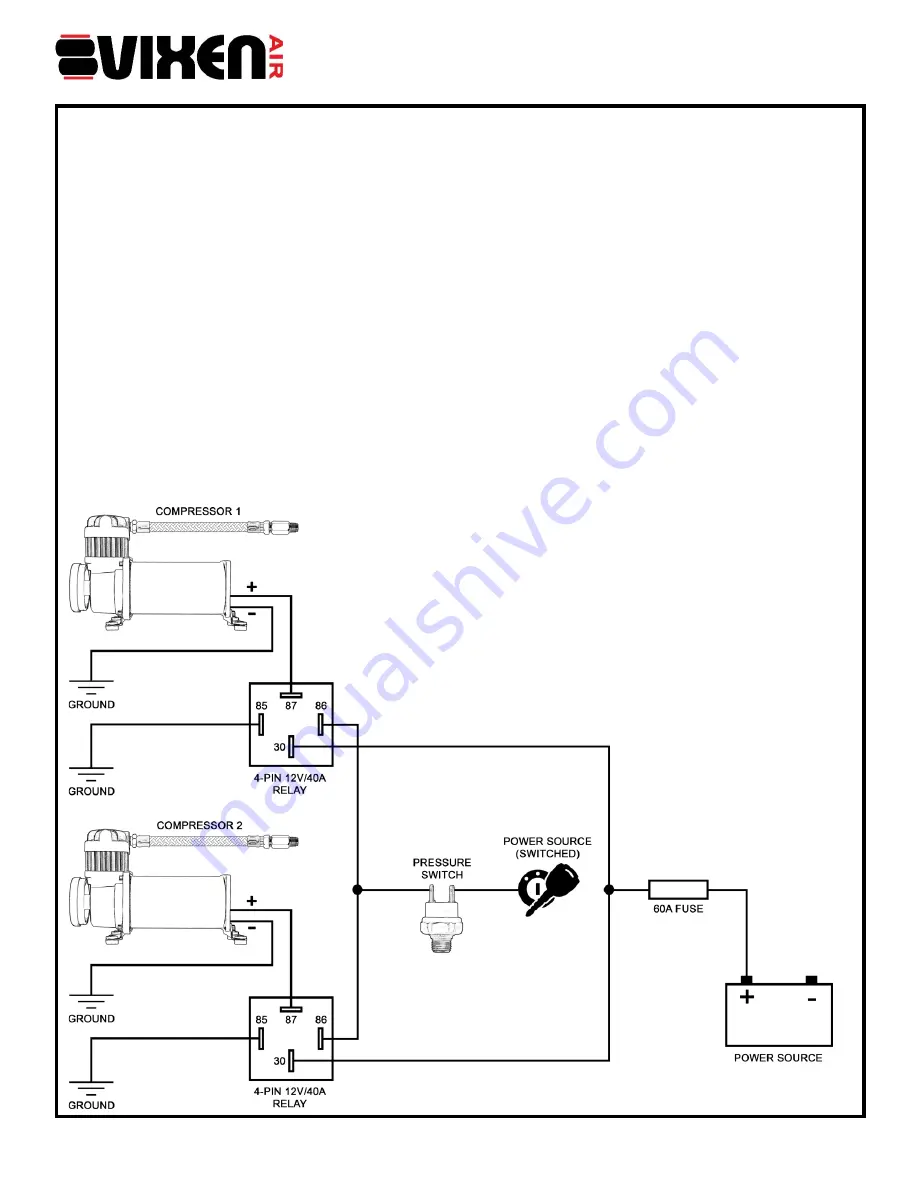

ELECTRICAL CONNECTION

COMPRESSOR

Red wire (positive) of the compressor is connected to

PIN 87

on the relay.

IMPORTANT

: Make sure to use

wire that is as heavy as the wire of the compressor

Black wire (negative) of the compressor and

PIN 85

of the relay are connected to ground.

Repeat above steps for the second compressor.

Connect together

PIN 86

of both relays and then connect it to one of the terminal of the pressure switch.

Attach the remaining terminal of the pressure switch to a power source in the vehicle that only gets power

when the vehicle’s ignition is on. Recommended connection points are: windshield wiper motor, blower motor

or an accessory terminal on the fuse panel. Make sure to use wire that is as heavy as the wire of the

compressor.

Connect together

PIN 30

of both relays and connect it to a constant power source using the provided 60A

fuse.

Both compressors are now set for use and will turn on automatically when air pressure in the air tank falls.

When air pressure reaches maximum PSI, they will turn off. If compressors fails to reach the maximum air

pressure of the tank, which is the Pressure Switch's cut OFF pressure, check all air connections for leaks.

While compressor are pumping, use soapy water or any bubble solution to perform this check. In case the

leak remains after tightening, re-apply thread sealant.

NOTE

: To makes installation fast, trouble free and professional, this kit comes with two Pre-wired Relay Plugs

(one for each relay), they will attach to the relay only in one position.