VXO4852C

INSTALLATION GUIDE

PAGE 1 of 5

BEFORE BEGINNING YOUR INSTALLATION

Read through the instruction guide before getting started with the installation. Professional installation is recommended for

this product.

CONTENTS

200 PSI Air Compressor (Chrome)

5 Gallon Steel Air Tank

170-200 PSI Pressure Switch

1/4" NPT Wing Style Drain Valve

Intake Air Filter with Remote Installation Kit (10 FT Hose)

4-PIN 12V/40A Relay with Pre-wired Plug

40A In-line Fuse with Waterproof Holder

Mounting Hardware

SAFETY INSTRUCTIONS

Do not attempt to disassemble, repair or customize this product.

Avoid setting up any parts of this product where there is a risk of falling off or risk of coming in contact with water.

Avoid reaching out to touch or pick up any fallen or water submerged parts.

Never leave this product unattended during use.

Intended for use by adults only.

During and immediately after use, avoid touching any part of the compressor with bare hands as it is very hot

during such periods.

Avoid use of product near flames, explosive materials, aerosol products or oxygen devices.

Be sure to pump nothing other than atmospheric air.

It is important to determine the maximum air pressure for any tool or attachment before using it.

Air sprayer or nozzle should always be pointed away from any part of the body.

The compressor has Thermal Overload Protection, if this protection activates, cut off the source of power and let

the unit cool down for about 30 minutes. This will reset the system and allow you to safely resume use of the air

compressor.

Make sure your battery ground is detached and the tank has no pressure before you begin the installation.

Employ equipment for eye protection during drilling operations.

Ensure that your air system has no pressure before you begin.

The specific voltage requirement for this on-board air system is 12 volt DC, therefore installation must be done to

a DC power source of 12 volts.

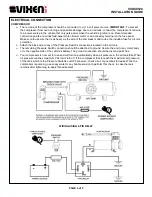

PLANNING YOUR INSTALLATION

Before beginning the installation, determine

each component’s spot.

Confirm you have the proper length of airline and wire.

Power wire to compressor should be kept short.

To power up the air compressor, make sure you use a 12-gauge wire or thicker.