VXO4852C

INSTALLATION GUIDE

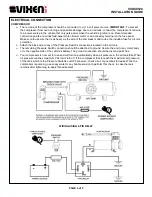

PAGE 3 of 5

AIR TANK

MOUNTING

Find a convenient mounting location in your vehicle for the air tank. Ensure ports are reachable before drilling

any holes.

Mark the location of holes using the mounting bracket of the air tank as a template, and then drill to size.

Using mounting hardware provided, secure the air tank.

IMPORTANT

: Do not mount on a flexible material.

The installation location of your tank’s accessories depends on your air system’s configuration.

PORT LOCATIONS AND THREAD SIZE (NPT)

PRESSURE SWITCH RATING

The included pressure switch has a rating of 170 PSI ON, 200 PSI OFF. When the air pressure in the air tank

is below the preset ON pressure (170 PSI), the compressor will automatically turn on and will start pumping

air into the tank. When the pressure reaches the cut OFF pressure (200 PSI), the compressor will be

automatically shut off.

DRAIN VALVE

This valve helps you drain the water that can collect in the air tank after long periods of use.

REMOVING CONDENSATION

:

To remove any condensation which has accumulated inside the tank, bleed the tank’s pressure until it ranges

from approximately 5 PSI to 20 PSI.

Remove the drain valve found at the tank’s bottom to drain the water from the tank. After draining the

accumulated condensation, reinstall the drain valve.

IMPORTANT

: Draining the system regularly will extend the life of the air tank.

MAINTENANCE

Make sure that electrical and fitting connections are regularly inspected, cleaned and tightened when needed.

Make sure mounting screws are regularly tightened if needed.

Drain weekly, to avoid excessive buildup of condensation.

Compressor features a washable air filter which should be cleaned using any mild form of liquid soap every

two mon

ths if it gets dusty. Just remove the front cover of the filter’s housing to reach it. Replacement time

frames depend on the operating environment and how often it is used.

Clean dirt and dust from heat spreader and motor housing of the compressor.

The motor of the air compressor has a maintenance-free lasting lubricant.

DO NOT LUBRICATE

.