VZN T5 SERIES

15

P/N 1011066 Rev. G 12/13

MAINTENANCE

Replacing the Ultra Filter Cartridge

NOTE: Always install new Carbon Element and new

TAC Cartridge Element after replacing the Ultra Filter

Cartridge.

1. Turn off water to the system by closing the Inlet Ball

Valve and Outlet Ball Valve.

2. Press the

FLUSH

button to flush the system and relieve

pressure. Repeat several times to ensure permeate

tank is empty.

3. Remove the Carbon Element and remove the TAC

Cartridge Element if present.

4. Locate the long hooked tubing on the right and discon-

nect the long end from the tee by pushing the collet

squarely against the face of the fitting.

5. With the collet pushed in place, pull the tubing from the

fitting with your right hand.

NOTE: Water may drain from the tubing as it is removed.

Make sure there is enough room next to the system to

remove the cartridge.

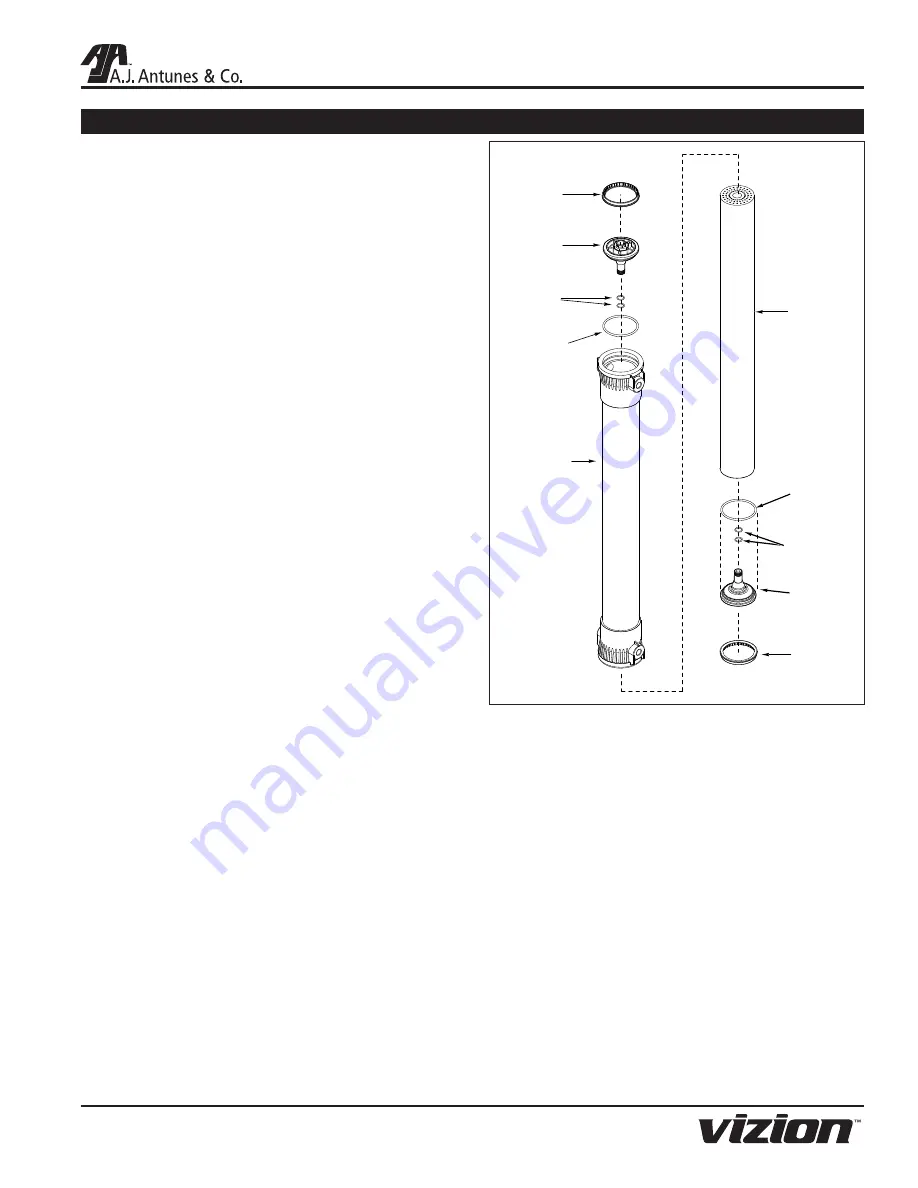

6. Remove the Snap Ring (Figure 8) from the Ultra Filter

Housing. Grab the raised lug with a pair of pliers and

pull towards the center of the End Cap and away. The

Snap Ring should lift out of its groove.

7. Remove the End Cap, End Cap O-Ring, and Cartridge

(Figure 8) from the housing.

NOTE: If the Cartridge does not easily come out of the

Housing, remove the opposite End Cap for assistance

during Step 5.

8. Inspect the Large End Cap O-rings and End Cap O-ring

for nicks or cuts. Replace as needed.

9. Lubricate all O-rings with a food-grade silicone lubri-

cant. Apply a light coating of lubricant to the inside cen-

ter tube at both ends of the new cartridge.

10. Record the serial number of the new cartridge. The

cartridge serial number is engraved on one end of the

outer tube (for example: 05K 12013).

11. Install the End Cap O-ring on the End Cap and insert

the Large End Cap into the end of the new cartridge.

12. Position the new cartridge and End Cap at the housing

and gently insert into the housing.

13. Press the End Cap into position until it is fully seated

and the Snap Ring groove is visible.

14. Install the Snap Ring by guiding the non-lugged end

into the groove first, pushing outward and working

around the ring until it snaps into place.

NOTE: Make sure that the Snap Ring is fully seated

before turning the water on.

15. Reattach the tubing that was removed in Steps 3 and 4.

Be sure the tubing is pushed past the O-ring.

NOTE: Make sure the fitting is completely inserted onto

the tubing past the O-ring. A loose connection results in

leaking at the point of connection.

16. Rinse the new Ultra Filter Cartridge before placing the

system back into operation. Follow the

Rinsing the

Ultra Filter Cartridge, Sanitizing the System and

Lines, and Rinsing the Carbon Element and TAC

Cartridge

procedures in the Installation section of this

manual to complete the cartridge change.

17. When rinsing is complete, repressurize the system by

opening the Outlet Ball Valve then opening the Inlet Ball

Valve.

Figure 8. Replacing the Ultra Filter Cartridge

Snap Ring

Ultra Filter

Housing

Ultra Filter

Cartridge

End Cap

O-Rings

End Cap

Snap Ring

End Cap

End Cap

O-Rings

Cartridge

O-Ring

Cartridge

O-Ring