VZN T5 SERIES

18

P/N 1011066 Rev. G 12/13

MAINTENANCE (continued)

Changing the Interval Setting

Resetting the Timer Program

During the normal operation, the system will flush accord-

ing to the set interval. It is possible the system will flush at a

time of high water use. If this poses a problem, the controller

can be reset. Unplug the power supply, wait for 5 seconds,

and then plug the power supply in. When power is restored

to the controller, it will automatically enter Flush Mode. The

controller will then begin timing from the point when power is

restored based on the interval setting selected.

Flush

Interval

Button

Hold Time

Button

LED

Flush

LED

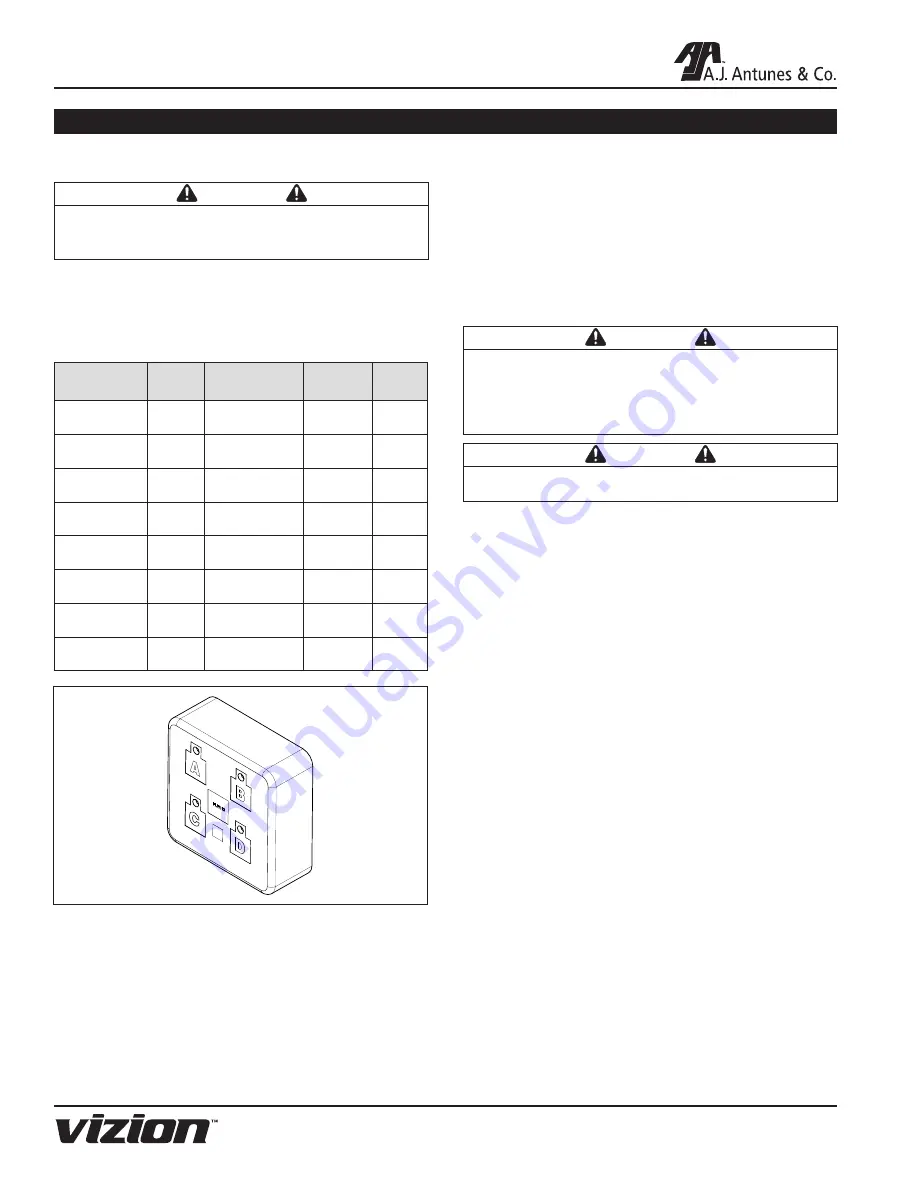

15 minutes

A

10 seconds

On

On

30 minutes

B

10 seconds

On

On

45 minutes

C

10 seconds

On

On

1 hour

A

5 seconds

On

Off

4 hour

B

5 seconds

On

Off

6 hours

C

5 seconds

On

Off

12 hours

D

5 seconds

On

Off

24 hours

D

10 seconds

On

On

CAUTION

Changing the flush interval can cause the Ultra Filter to

plug prematurely and may reduce the life of the filter.

Consult the factory for more information.

Though not recommended, the interval setting on the

Universal Pulse Controller can be changed. If the setting must

be changed, use the chart below. Press and hold the corre-

sponding button. After 5 seconds, the Button LED will turn on.

After 10 seconds, the Flush LED will also turn on.

Figure 12. Universal Pulse Controller

Semi-Annual Tasks

Check Permeate Tank Air Pre-Charge

It is recommended the permeate tank air charge be

checked every six months.

Tools and supplies required:

•

Air Pressure Gauge, 5‒40 psi range (0.3‒2.7 bar)

with tire valve (Schrader Valve) connection

CAUTION

Air pre-charge should only be checked and adjusted

under zero system pressure. The system must be

depressurized before checking the tank pre-charge.

Do NOT adjust the tank air pre-charge with the system

under pressure.

CAUTION

Be careful when adding air to the tank. Do NOT add too

much air pressure to the tank.

• Source of compressed air (manual bicycle tire

pump or air compressor)

1. Refer to Figure 1. Depressurize the system by

closing the Inlet and Outlet Valves and opening

the Rinse Valve. Make sure the Permeate Tank is

fully drained.

2. Unscrew the protective cap from the air valve on

the tank.

3. Use the pressure gauge to check the tank pre-

charge for pressure.

NOTE:

If any water comes out the air valve, the tank

bladder has ruptured and the tank needs to be

replaced.

4. The permeate tank should have a pressure of 28-

31 PSI.

• To add pressure to the permeate tank, use a

manual bicycle tire pump or other source of

compressed air.

• To release pressure from the permeate tank,

press the center pin on the air inlet valve.

5. Once the permeate tank is at 28-31 PSI, replace

the protective cap on the air valve.

6. Pressurize system by closing the Rinse Valve and

opening the Inlet and Outlet Valves.