VMAC – Vehicle Mounted Air Compressors

Toll Free:

1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

29

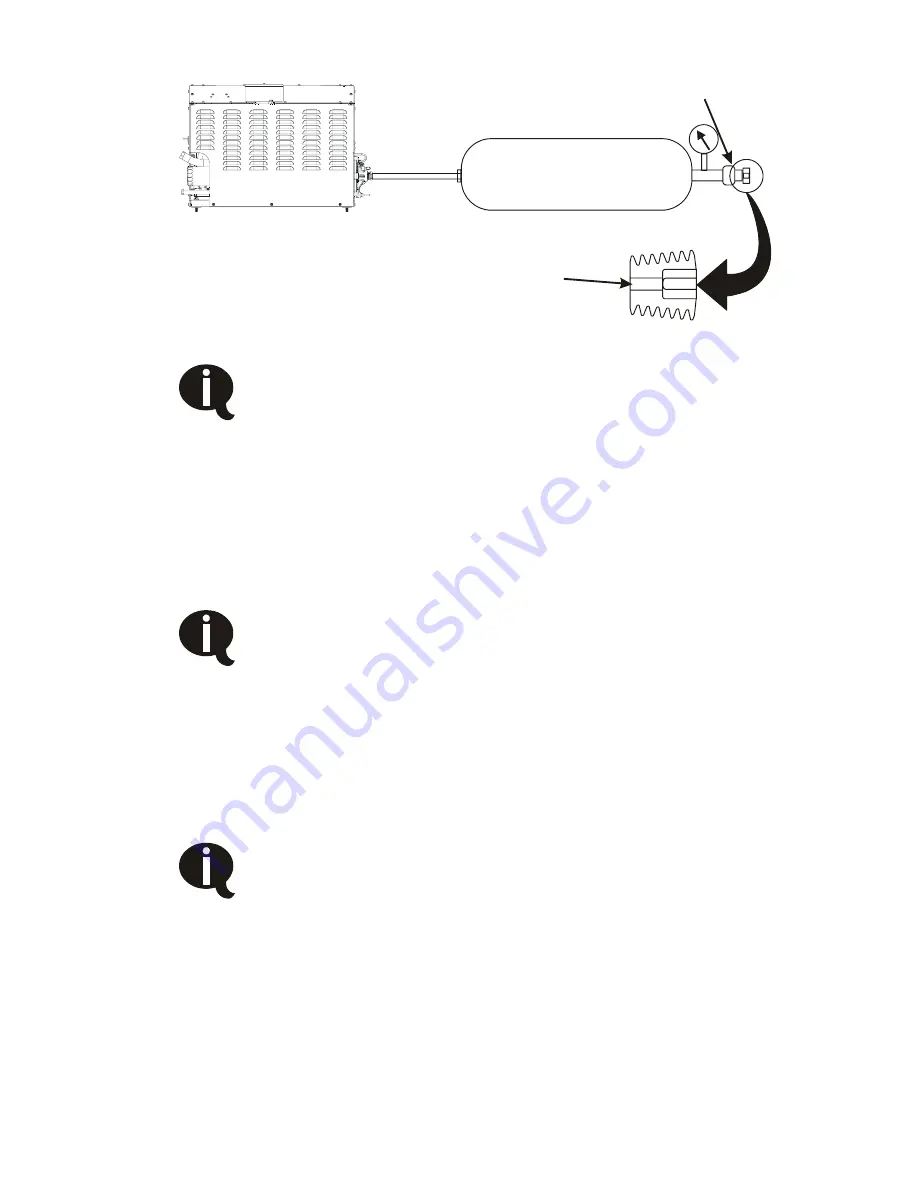

Compressor

Air receiver

Ball valve

Orifice drilled in plug

Pressure gauge

Figure 19 – Test setup

If the air pressure drops below 100 psi, increase

hydraulic flow to bring the pressure back up. Do not

exceed hydraulic flow specifications

9. Test the system for 1 hour at the maximum duty cycle. Make

sure that you can read the temperature for the duration of the

test without disturbing the system by opening cabinets or other

functions.

10. Record “T

2

” every 30 seconds during the last 10 minutes of the

test. Record “T

1

” at the 50 minute and 60 minute marks.

Copy and use Form 2 on the following page for your

calculations.

11. For the analysis, “T

1

” is the average of the two “T

1

” readings and

“T

2

” is the average of the 20 “T2” readings taken in step 10. “T

3

”

is the maximum ambient temperature to which the vehicle will be

exposed.

If the system shuts down at any point during the test,

check the LEDs on the the top of the unit for Flash

Codes and cross-reference them to the table in the

Owner’s Manual. If the system shut down due to and

over-temperature condition, check all oil levels, improve

ventilation and repeat the test once the system has

cooled.