VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

73

Installing the Control Components

VMAC

wire

Heat shrink

tube

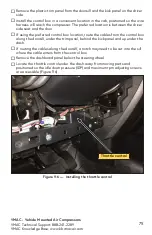

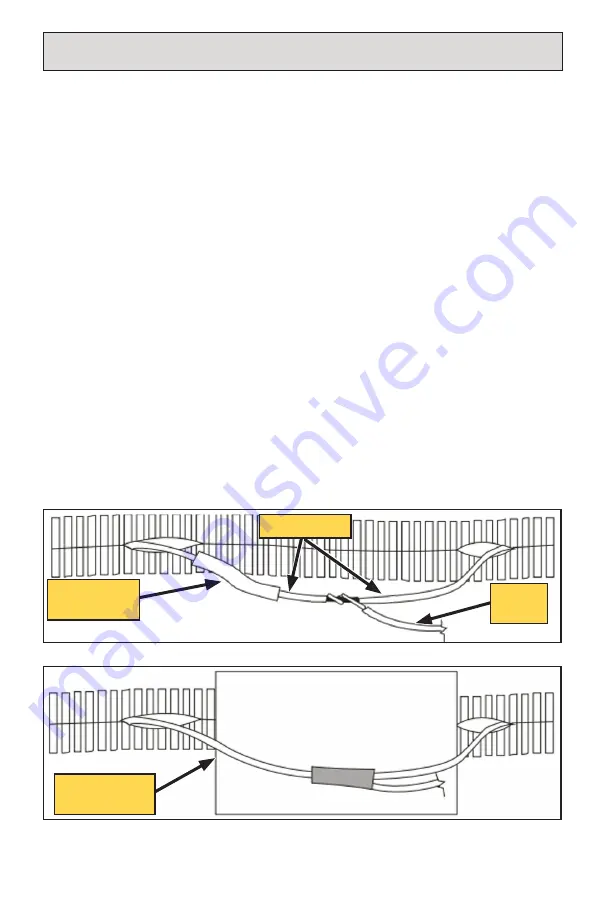

Figure 113 — Solder spliced joint

OEM wire

Heat shield

material

Figure 114 — Seal soldered joint

Best Practices

•

To confirm a good ground, use an ohm meter to measure the resistance

between the ground point and the negative battery terminal. Resistance

should be less than 1 Ω.

•

Route all wires to ensure they will not contact hot, sharp or moving parts

(including the park brake mechanism, steering column, and pedals).

•

Before drilling any holes ensure there are no OEM wires, hoses, or

components that may be damaged.

•

Do not use a test light to probe for power on vehicle circuits, the increased

current draw of the test light may damage components.

•

Whenever possible, solder all electrical connections and protect the joint

with heat shrink.

•

Apply loom to all wiring:

Ǜ

Use high temperature loom in areas where high temperatures may be

expected.

Ǜ

Use spiral loom in areas with high vibration.

Splicing into OEM Wiring (Figure 113, Figure 114)

VMAC recommends against cutting OEM wires whenever practical. The preferred

method is to remove the pin from the connector using an appropriate tool and

slide the shrink tube onto the wire. Strip the wire at the desired location and solder

the VMAC wire into place. Slide the shrink tube up to the soldered joint and seal

it. Finally, replace the pin in the connector, taking special care to ensure the pin is

fully inserted and the locking tabs are engaged.