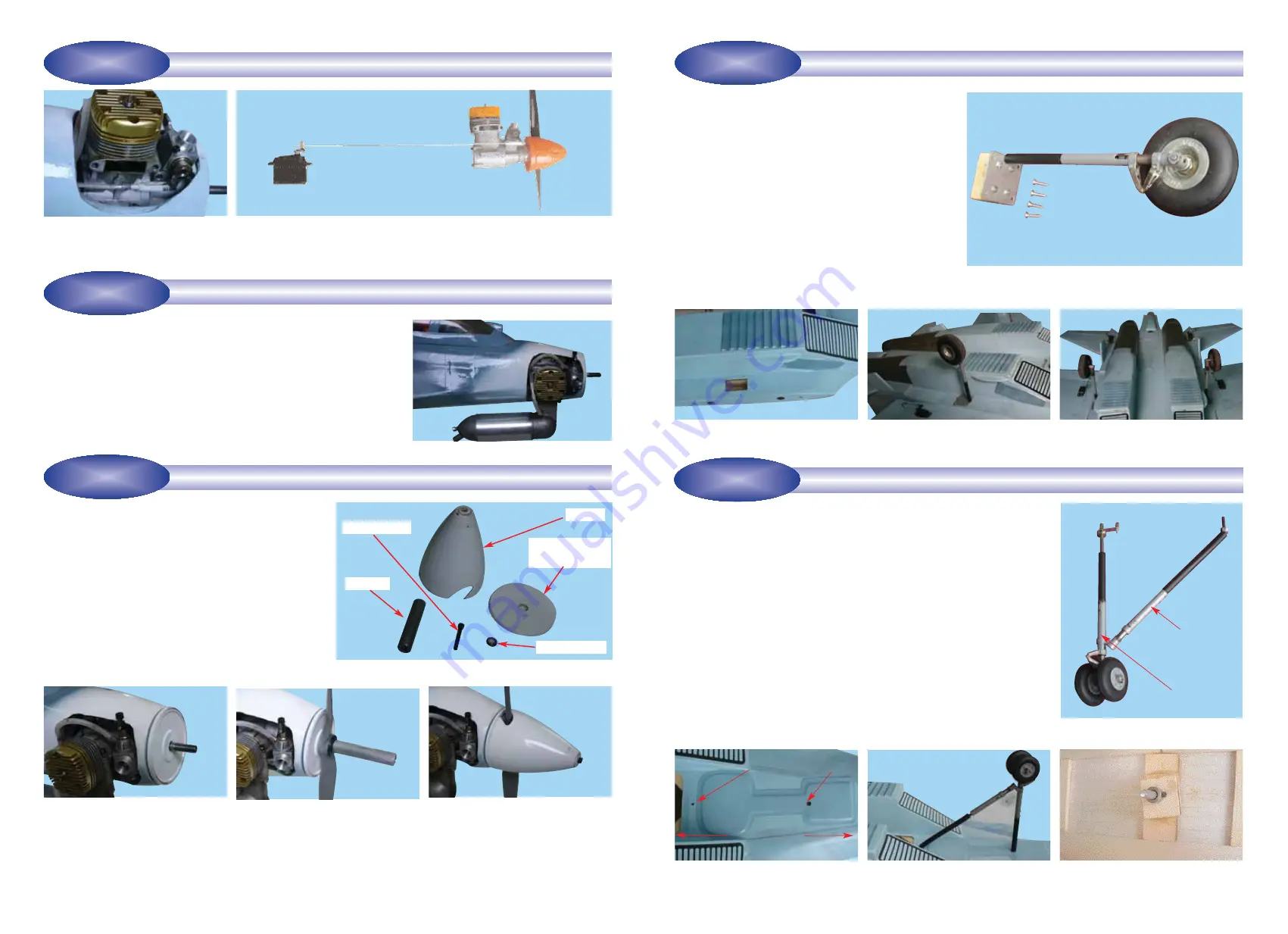

Step 8.1

Invert the fuselage and locate the pre-drilled main

landing gear mounting cavities on the bottom of the fuse-

lage. See 8B.

Step 8.2

Insert one of the pre-assembled main landing

gear into place. Use 4 sheet metal screws to attach the

landing gear to the fuselage. See 8C.

Step 8.3

Repeat step 8.2 to attach the second main land-

ing gear to the fuselage.

Step 15.1

Consult your engine manual and select a suit-

able propeller. See 15A

Step 15.2

Install the thrust washer, the spinner backing

plate, the propeller, the prop washer, and the prop nut sup-

plied with the spinner. Ensure that they are all firmly

attached. See 15B, 15C

Step 15.3

Trial fit the spinner cone and spinner cone

retaining screw. If necessary enlarge the cutouts in the

spinner cone to allow adequate clearance for the propeller.

See 15D

Step 15.4

Double check that the spinner cone retaining

screws are firmly attached.

Step 9.1

Review illustrations 9A, 9B and 9C then insert the front nose gear oleo

strut and support strut into the mounting holes in the bottom of the fuselage.

Step 9.2

Use the 4mm collar with set screw to secure the support strut in place.

See 9D.

Step 9.3

After securing the support strut into place, carefully pull the oleo strut

back out of its fuselage hole. See 9E. Do not detach the support strut

.

Step 9.4

Working inside the fuselage, pass the nose gear steering rod through

the EZ connector attached to the steering arm. See 9F. Do not tighten the steer-

ing arm set screw yet.

Step 9.5

Working from outside the fuselage carefully re-insert the oleo strut

back into its fuselage hole and then from inside the fuselage pass the oleo wire

through the steering arm. See 9G. Tighten the steering arm set screw.

7

8A - Components of one main landing gear with oleo strut.

INSTALLING THE MAIN LANDING GEAR

STAGE 8

INSTALLING THE NOSE GEAR

8B - Main landing gear location on

the fuselage (left side)

8C - Mount the main landing gear to

the fuselage.

8D - Both main landing gear mounted

to the fuselage.

15B - Install the spinner backing plate

15C - Install the propeller, the prop

washer and the prop nut

15D - Install the spinner cone using

the retaining bolt. Ensure the retain-

ing bolt is tight and secure

9B - Turn over the fuselage & locate

the mounting holes for the oleo strut

and the support strut.

9C -

Insert the front nose gear oleo

strut and the support strut.

9D - Use the 4mm collar and set screw

to secure the support strut.

9A - Oleo nose gear & strut assembly

Identify the nose gear components per illustration 9A

- 1 completed oleo nose gear assembly with strut, strut support and wheels

- 1 steering arm with pre-installed EZ-connector

- 1 collar (4mm)

10

15A - Aluminum spinner complete with all hardware (sup-

plied)

INSTALL THE PROPELLER AND THE SPINNER

STAGE 15

Identify the main landing gear components shown below:

- 2 pre-bent oleo main landing gear sets pre-assembled

with struts, wheels and mounting plates.

- 8 sheet metal screws (3x15 mm)

STAGE 9

Step 14.1

Install the muffler. Connect the fuel tank pressure line to the muffler

pressure nipple.

Step 14.2

Connect the fuel tank fuel line to the carburetor fuel inlet nipple.

Step 14.3

Double check that you have connected the metal fuel line from the

tank to the carburetor and that you have connected the metal pressure line

from the tank to the muffler.

Step 14.4

The fuel tank refueling line is used only when filling the tank. Keep

the line plugged after fueling is completed.

CONNECTING THE FUEL LINES

STAGE 14

CONNECTING THE THROTTLE CONTROL ROD TO THE ENGINE.

13B - Connect the servo arm to the engine throttle arm using the throttle con-

trol rod

13A - Connect the clevis to the engine

throttle arm

STAGE 13

Strut support

Strut support hole

Tail Nose

Nose gear hole

Oleo strut

Thrust washer

Retaining bolt

Spinner

Prop nut

Spinner backing

plate