Step 12.1

Trial fit your engine to the engine mount. Check engine compartment clearances and modify using a Dremel

tool to allow your engine to sit properly on the mounts. Ensure the spinner back plate clears the front of the fuselage by

1/16 - 3/32 in. (1.5 - 2.5 mm). See 12B

Step 12.2

Once you have positioned the engine on the mounting beams, mark the location of the engine mounting holes.

See 12C

Step 12.3

Center punch the hole locations on the beams. Drill 3/32 in. (2.5mm) pilot holes at right angles through the

beams. Put a drop of oil in each hole. Use four #4 x 25 mm sheet metal screws to mount the engine. See 12D

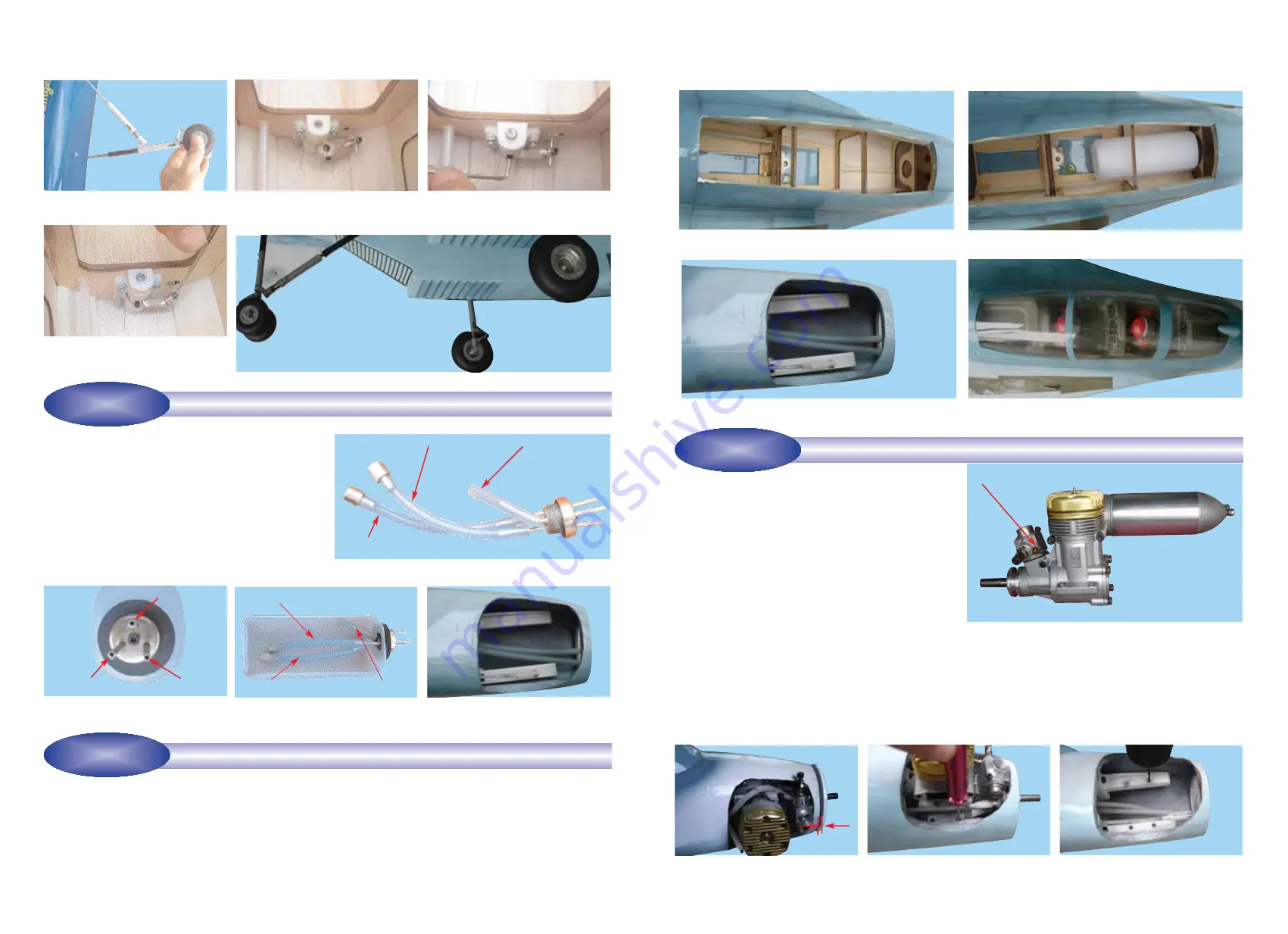

FITTING THE FUEL TANK

8

10B - Fuel tank and stopper assembly

(front view)

11B - Fuel tank assembly in position

10C - Illustration of fuel line position-

ing inside cutaway of the tank

11C - Run external pressure, fuel and refuel lines through

the firewall from the tank to the engine area

11D - Re-install the pilots, instrument panel and canopy

10D - Fuel tank installed into the fuse-

lage after adding external fuel lines

from tank forward to engine area

To assemble the fuel tank you will need the following items:

- The fuel tank and fuel stopper assembly (supplied)

- 2 clunks (supplied)

- About 10 in. (25.4 cm) of medium ID silicone fuel line (DUB-

197 or DUB-222 or similar)

10A - Use 2 in. (50 mm) for the pressure line and 4 in. (100

mm) for the fuel and refuel lines.

Pressure line

Connect to the fuel line

Pressure line

Pressure line

Fuel line

Fuel line

Fuel line

Refuel and empty line

Refuel and empty line

Refuel line

STAGE 10

INSTALLING THE FUEL TANK INTO THE FUSELAGE

STAGE 11

11A - Remove the cockpit and instrument panel from the

fuselage

9

INSTALLING THE ENGINE

STAGE 12

The VMAR SU 27 FLANKER is designed for .60 to .91

size two stroke engines. The model has not been designed

to accommodate four stroke or gas powered engines.

12A - .91 2 cycle engine. VMAX 91PRO shown

12B - Allow for gap between the spin-

ner back plate and the fuselage

12C - Mark the location of the engine

mounting holes

12D - Drill 3/32 in. (2 mm) pilot holes

at right angles through the beams

Step 11.1

Remove the external screws and carefully detach the canopy from the fuselage. Then remove the internal screws

and detach the pilots and instrument panel from the fuselage. See 11A

Step 11.2

Install the fuel tank into the fuselage. Use foam sheet (supplied) to cradle the tank. See 11B

Step 11.3

Run external pressure, fuel and refuel lines through the firewall from the tank to the engine area

. Protect the

tubes from contamination See 11C

Step 11.4

After trial fitting the tank and tubing, apply silicone sealant to both sides of the black foam rubber like gasket and

around neck of the tank. Press tank firmly against former . Hold in place until sealant cures.

1/16 in. to 3/32 in. (1.5 to 2.5 mm)

9E - Carefully pull the nose gear oleo

strut out of the fuselage.

9F - Pass the nose gear steering rod

through the EZ connector. Do not

tighten yet.

9G - After re-inserting the nose gear

oleo strut, align and tighten the

steering arm set screw.

9H - Align and secure the EZ connec-

tor to the nose gear steering rod

using the set screw.

9I - Completed installation of the main and nose gear assemblies.

Step 11.5

Re-install the instrument panel and pilots into the fuselage using the internal screws

. Then re-install the

canopy using the external screws See 11D

Step 9.6

Align the nose gear straight ahead and secure the EZ connector to the nose gear steering rod by tightening the

EZ connector set screw. See 9H.