v8.05 - Depósito legal y Copyright 2008. Todos los derechos reservados.

VMB ESPAÑOLA, S.A.

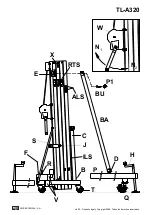

4. INSTRUCTIONS.

4.1 -

Situate the lift on its transport wheels (

T

)

upon a flat and stable surface.

When erecting the lift in open air, the risk of

wind is prevalent.

Where wind speeds exceed 30 Km/h it is

essential to tie the lift. 2 lateral fixing points (

X

)

are situated at the top of profile 2, where

tensors should be attached and fixed on secure

and firm ground (NEVER ON A VEHICULE OR

ANYTHING THAT CAN MOVE).

4.2 –

Remove the outriggers from their

transport compartments (

S

) and place them in

the working position (

V

) ensuring they are fixed

with the security locks (

R

). The long outriggers

are placed and the front beneath the load. The

short outriggers are placed at the back.

4.3 –

Remove the front support bars (

BA

) from

their transport compartment (

S

) and place them

in their corresponding fixed position (

D

) on each

front outrigger and at the top of the first profile

(

E

) ensuring they are fixed with the pins

provided

P1

.

To correctly fix the front support bars (

BA

),

adjust the support of the front outrigger by

turning the stabiliser handel in the necessary

direction.

Insert clips (

BU

) and security pins (

P1

).

Adjust the vertical position of the lift with the

stabilisers (

Q

) turning the handels so that the

spirit level is centred (

F

).

4.4 –

Let go of transport security

B

, remove

the forks and place them horizontally.

Place the lifting carriage at the required height

so that the Line Array buffer can be attached.

The careful positioning of the front outriggers

enables the Line Array to fit between them and

ease assembley on to the forks.

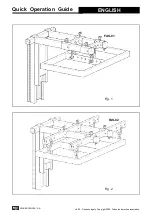

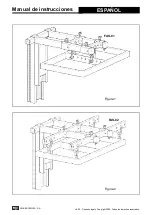

Support

FAS-01

is to be fixed to the forks by

either 1 or 2 points. See fig.

1.

If the Line Array Buffer has 4 link points use

the

FAS-02

support which enables the Line

Array to be flown from 4 points, see fig.

2.

Both supports

FAS-01

and

FAS-02

are inserted

on the forks as follows:

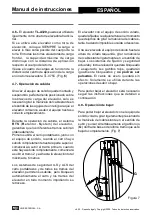

The Line Array cabinets will be attached to their

buffer with the angles calculated according to

the acoustic coverage required.

This ensures the Line Array cabinets can be

curved in function with the necessary degrees

required between them.

The system should be attached at the

necessary distance to achieve the required

curve. The last cabinet should not hit the body

of the lift. See fig.

3.

To ensure the maximum security margin it is

necessarry to always attach the Line Array at

the minimum distance possible from the body

of the lift. This will mean that the bottom cabinet

is as close as possible to the body of the lift.

See fig.

3A

.

To avoi d overloading do not seperate

uneccessarily the Line Array from the body of

the lift. See fig.

3B

.

Quick Operation Guide

ENGLISH

Summary of Contents for TL - A320

Page 40: ......