Valvole brevettate per compressori rotativi a vite e pistoni

Patented valves for piston and screw rotary compressor

V.M.C. s.p.a.

Via Palazzon 35 – 36051 Creazzo (VI) – ITALY

Internet

www.vmcitaly.com

-

Phone

+390444/390444/341115 -

Fax

+390444/275112

TIPO

TYPE

DC

REVISIONE

REVISION

00

DATA

DATE

02/18

GRUPPO

LINE

744

ARTICOLO

ARTICLE

.YX

MODELLO

MODEL

X3

Pagina 42 di 43

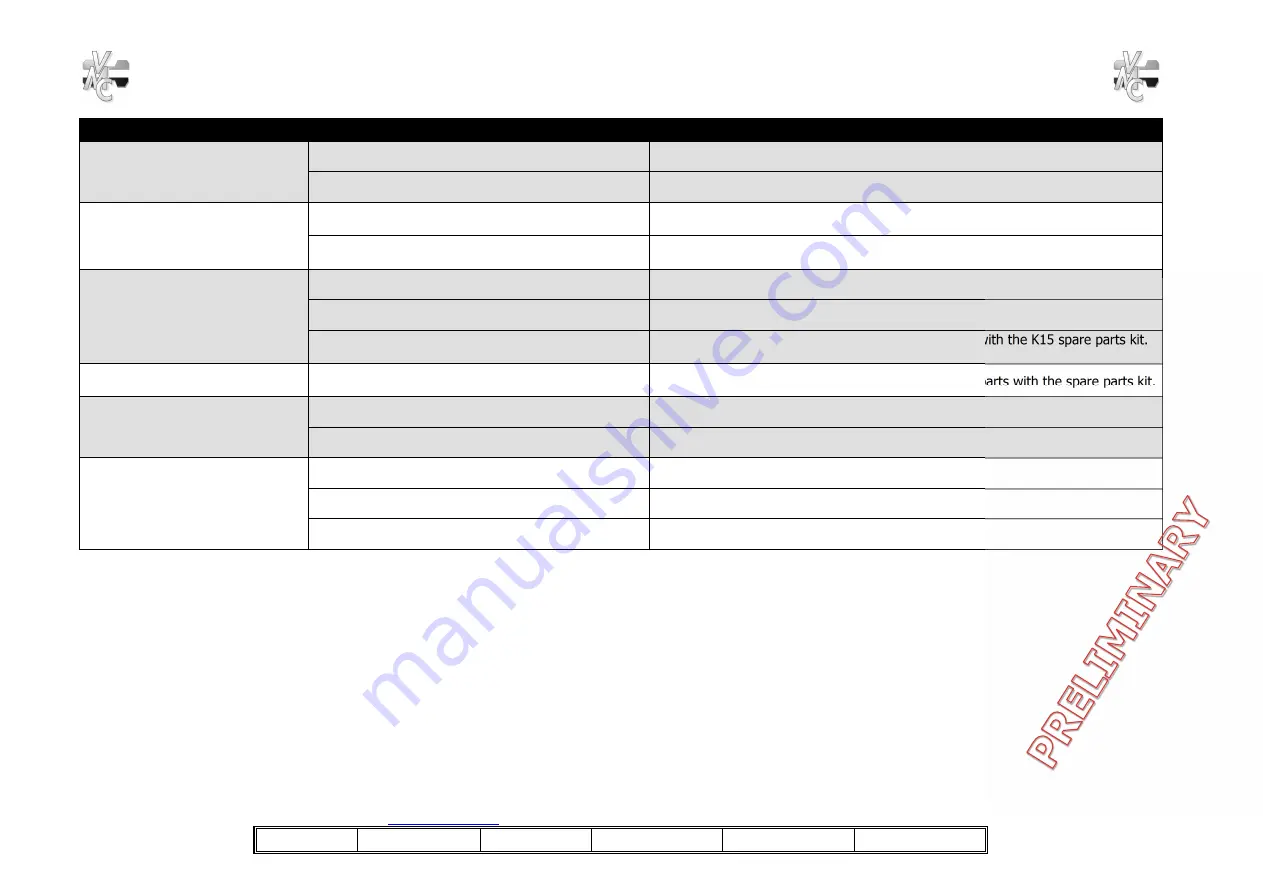

SYMPTOMS

PROBABLE CAUSE

CORRECTIVE ACTION

During unloading phase,

pressure increases up to safety

valve opening

1-The intake valve remains open.

1-Check the valve. If necessary, replace the damaged parts with the spare parts kit.

2-The calibrated nozzle is clogged.

2-Remove the calibrated nozzle. Clean or replace it.

Oil leakage from intake valve

only when the machine is

switched off: oil soaked-up air

filter

1-The intake valve does not work properly

(does not close)

1-Check the valve. If necessary, replace the damaged parts with K9 spare parts kit.

2-The non-return valve of intake valve does not work

correctly.

2-Check it and clean it.

Oil soaked-up air filter during

unloading phase

1-Too high level of oil in the tank

1-Check oil level on separator tank (see the chapter 6).

2- Clogged separator filter

2- Replace the separator filter.

3-The recovery oil viewer is dirty or does not work

appropriately.

3 -Clean it or if necessary, replace the damaged parts with the K15 spare parts kit.

If separator filter is clogged up, replace it.

The compressor remains under

loading phase.

1-The intake valve does not work properly

(does not close)

1-Check the valve. If necessary, replace the damaged parts with the spare parts kit.

Rotor seizure

1-Unknown particles inside.

1-Call VMC technical support.

2-Insufficient lubrication.

2-Call VMC technical support.

Presence of oil in the outlet of

minimun pressure valve

1-Separator filter damaged.

1-Replace the separator filter.

2-Oil recovery viewer obstructed.

2-Clean the oil recovery viewer.

3-Separator nipple with o-rings damaged.

3-Replace K1 spare parts kit.