Maintena nce

WBV.PU.002.EN VX215QD V2.0

41

8

Maintenance

WARNING

Risk of injury (catching, crushing, collision) due to rotating rotary lobes if the machine starts up

unexpectedly!

Before starting maintenance and repair work (opening covers, disassembling connectors) and before

troubleshooting, switch the machine off and secure it against being switched on again.

WARNING

Risk of injury from working materials escaping under high pressure!

When the drain plugs on the gearbox and buffer chamber are loosened or the buffer fluid tank cover is

opened, working materials can spray out under high pressure.

•

Personnel must wear suitable protective clothing.

•

Before carrying out maintenance and repair work, release the buffer chamber pressure.

•

To protect against fluids spraying out, carefully and slowly open the buffer chamber, the bearing cover

on the QD cover and the gearbox. Cover the valves or screws to be removed with a cloth or similar

item where appropriate.

8.1

Buffer chamber

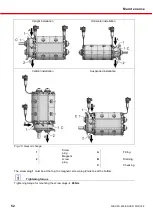

In the following chapters, we describe the following possible

buffer chamber assemblies:

1

Chapter

"Pressurisable buffer fluid tank"

2

Chapter

"Depressurised quenching fluid tank"

3

Chapter

"Pressure valve"

4

Chapter

"Plugs"

Buffer chamber assemblies act to improve control of the pump shaft seal. The fluid level and the set

pressure can be monitored, depending on the design.

Electronic buffer chamber monitoring is also possible. Ask us for more information.

If your pump is equipped with a dry buffer chamber or a circulation system, please read the corresponding

Chapter "

"Dry buffer chamber" sealing system" or "Circulation system on the cartridge mechanical seal".