Maintena nce

WBV.PU.002.EN VX215QD V2.0

49

8.3

"Dry buffer chamber" sealing system

This sealing system is only used if it is essential to prevent buffer chamber fluid from getting into the pump

medium. It is used for pumps that pump pure, non-abrasive media, e.g. water.

To prevent contamination of the pump medium,

no fluid

must be filled into the buffer chamber of pumps with

the "dry buffer chamber" sealing system.

Medical white oil, part no. BSS.010, can be used as the gear oil.

Notice

White oil, part no. BSS.010: approved only for continuous operation up to 50% of the max. approved

differential pressure of the pump

Chapter

"Specifications".

Please contact us.

ATTENTION

To protect against seal damage, dry running of the pump must be avoided on pumps with a dry buffer

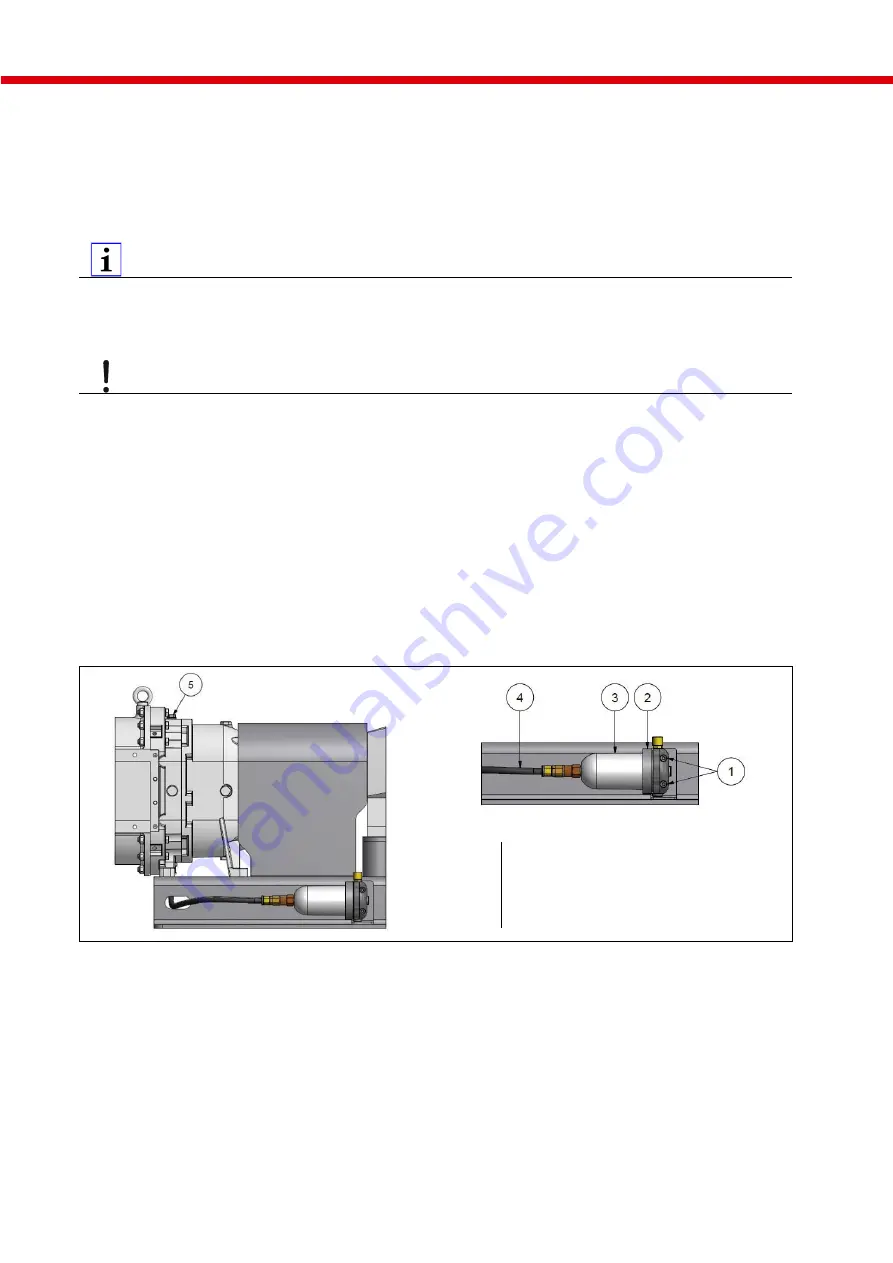

chamber. Before start-up, remove the plug from the vent screw (5)

Fig.

"Installation example - dry buffer

chamber" and completely fill the pump chamber with fluid.

Combination of mechanical seal rings in this sealing system

Type of construction: block ring

Mating materials: AISI 304/AISI 316 Ti tungsten carbide coated/carbon

Installation

Fig.

"Installation example - dry buffer chamber"

Connect tank (3) with connecting pipe (4) at the bottom of the buffer chamber. The tank must be installed

below the buffer chamber in order to collect medium leakage. The fluid level in the tank should come up no

further than the bottom edge of the buffer chamber.

1

Wing nut

2

Union nut

3

Tank

4

Connecting pipe

5

Vent screw

Fig. 18: Installation example - dry buffer chamber

Monitoring the buffer chamber

If the tank (3) is filled with leaked fluid (e.g. pump medium, gear oil or condensed water), undo the wing nuts

(1), unscrew the tank cover (union nut (2)) and drain the tank. If the tank is filled by more than half within a

month, please contact our service department.