Maintena nce

50

WBV.PU.002.EN VX215QD V2.0

8.4

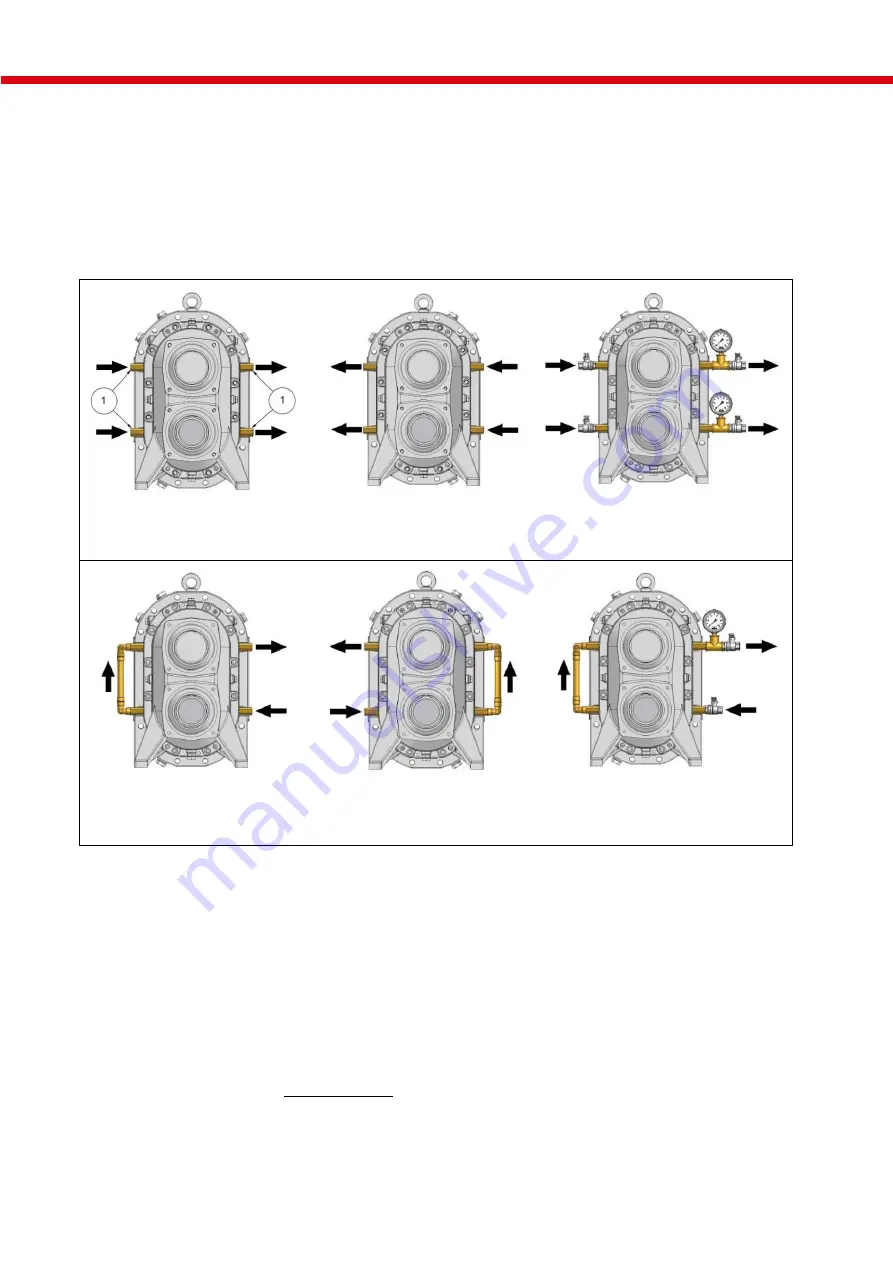

Circulation system on the cartridge mechanical seal

The cartridge mechanical seal is flushed by a circulation system. The flushing liquid, e.g. oil, water or

glycerine, must be compatible with the pump medium.

Technical prerequisites for the circulation system

•

Flushing connectors (1) on the pump

Fig.

"Flushing operation".

•

Cartridge mechanical seal with the "double mechanical seal" arrangement. The selection of materials

for the cartridge mechanical seal depends on the flushing medium.

Parallel

Connection example for flushing

pressure and volume flow

adjustment

In series

Connection example for flushing

pressure and volume flow

adjustment

Fig. 19: Flushing operation

Adjustment of flushing pressure and volume flow

Fig.

"Flushing operation - connection example for flushing pressure and volume flow adjustment".

Adjusting the flushing pressure

The flushing pressure can be adjusted and monitored with a pressure gauge.

The flushing pressure should be about 0.5 bar higher than the average pressure in the pump.

Flushing pressure = 0.5 bar + (pressure on the suction side + pressure on the discharge side) / 2

Example:

A pump primes with 0.4 bar suction and discharges with 2.0 bar overpressure.

Pressure on the suction side:

–0.4 bar, pressure on the discharge side: 2.0 bar

Flushing pressure = 0.5 bar +

2

)

bar

2

bar

4

,

0

(

= 1.3 bar

In this example, the flushing pressure is 1.3 bar.

If there is an increased risk that medium will get between the sliding surfaces, the pressure should be

increased by 1 bar (in the example: 1.3 bar + 1 bar).

Independently of this, the flushing pressure should be no more than 10 bar with a double mechanical seal.