Maintena nce

WBV.PU.002.EN VX215QD V2.0

51

Adjusting the volume flow

The volume flow of the flushing fluid depends on the application and the degree of contamination. The higher

the volume flow, the better the flushing effect.

The volume flow should be at least 0.1 l/min and no more than 10 l/min.

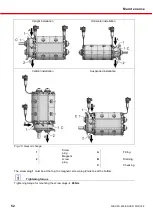

We recommend the flushing operation as specified in

Fig.

“Flushing operation - parallel":

•

Every cartridge mechanical seal is flushed with clean flushing fluid.

•

A possible defect of the single cartridge mechanical seal is detected.

Alternatively, the flushing operation can be done as indicated in

Fig.

“Flushing operation - in series":

•

Flushing fluid is supplied only via the lower flushing inlet and reaches the upper flushing outlet via the

two cartridge mechanical seals.

Note with this alternative flushing operation:

A possible defect cannot be assigned to the single cartridge mechanical seal.

Possible impurities of the cartridge mechanical seal rinsed for the first time can get into the

subsequent mechanical seal.

8.5

Gearbox

8.5.1

Gear oil - grade

We recommend the oils listed in

Chapter

"Oils".

8.5.2

Gear oil - quantity

4.5 litres

8.5.3

Gear oil

– inspection and change

Fig.

"Gear oil change"

Inspect the gear oil

and top up small quantities up to the seal indicator pipe (C) (only top up when the

gearbox is at a standstill):

every 500 operating hours, however at least every 3 months

Change gear oil:

•

After the first 20 operating hours

•

Every 2000 operating hours

The buffer or quenching fluid should be changed at the same time as the gear oil change

Chapter

"Buffer

chamber assembly".

Environmentally friendly disposal

Treat gearbox oils like hazardous wastes and dispose of properly.