Repair

64

WBV.PU.002.EN VX215QD V2.0

9.6

Change of cartridge mechanical seal

9.6.1

Change of cartridge mechanical seal on the gearbox

Cartridge mechanical seal

– installation/disassembly tool: Part no. PBA0082

Alternatively

:

Combination tool for lobe change

and

cartridge mechanical seal change

for pump sizes 226, 320: Part no. PBA0081

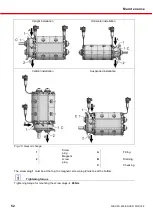

Fig.

“Cartridge mechanical seal on the gearbox”

1.

Reduce the pressure in the two buffer chambers if necessary

Chap.

“Buffer chamber”.

2.

Drain and clean the buffer chamber on the gearbox.

3.

If present, dismount the locking screws or flushing connectors for the circulation system

Chap.

“Circulation system on the cartridge mechanical seal” and

Fig.

“Flushing operation”.

4.

Drain gear oil.

5.

Follow the steps specified in

Chap.

“Lobe change” and

Chap.

“Wear plate change”.

6.

Remove the slotted set screws (1) of the cartridge mechanical seal (Fig. a)).

7.

Put on tool (A) and screw the cylinder head bolts (2) into the extracting boreholes of the cartridge

mechanical seal (Fig. b)).

8.

Pull out the cartridge mechanical seal evenly using the three hexagon head bolts (3) of the tool (A)

(Fig. b)).

9.

Change O-ring (4) in the bearing seal housing (Fig. c)).

10.

Before installing the new cartridge mechanical seal, carefully remove the burrs on the keyways and

clean the cartridge mechanical seal seat in the pump housing.

11.

Push new cartridge mechanical seal onto the shaft. Carefully oil the outer O-rings on the seal carrier

(pos. 5 in Fig. b)) before installation. Attention! Do not use mineral oil or grease for O-rings made of

EPDM. Use glycol as an alternative.

12.

If a circulation system is present, the flushing connector boreholes in the cartridge mechanical seal

must be aligned with the flushing connector boreholes in the bearing seal housing.

13.

To install the new cartridge mechanical seal, place the tool on the cartridge mechanical seal without

bolts.

14.

Push lobe (without fitting key) onto the shaft.

15.

Insert the pressure disc and the strain bolt.

16.

Tighten the lobe until the cartridge mechanical seal is flush with the pump housing.

17.

Reinstall any removed locking screws or flushing connectors.

18.

Remove the lobe again.

19.

Push O-ring and support ring onto the shaft.

20.

Before installing the lobes, thoroughly clean the contact surfaces of the lobes and gasket!

21.

Install lobes, wear plates and QD cover.

22.

Top up buffer or quenching fluid.

23.

Readjust the pressure in the two buffer chambers if necessary

Chap.

“Buffer chamber”.

24.

Top up the gear oil.