Page 10

/

TR001 DEFENDER™

www.vogelzang.com

VGZ-026 / 20120306.0

CHIMNEY CONNECTIONS continued …

or a knowledgable inspector. Consult your insurance

company if you cannot find a qualified expert.

CAUTION: NOT ALL FIREPLACES ARE SUIT-

ABLE FOR CONVERSION TO ACCOMMODATE

A WOOD STOVE. CHECK WITH A QUALIFIED

EXPERT.

Many prefabricated fireplaces are of the “zero-

clearance fireplace” category. These consist of mul-

tilayered metal construction. They are designed with

enough insulation and/or air cooling on the base, back

and sides so they can be safely installed in direct con-

tact with combustible floors and walls. Although many

prefabricated fireplaces carry endorsements from na-

tionally recognized organizations for use as fireplaces,

they have not been tested for connection to wood stove

heaters. Connecting a stove to such a device will void

the manufacturer’s warranty.

Venting a stove directly into a fireplace does not

meet code and should not be attempted. (This consti-

tutes connection to another appliance - the fireplace.)

The stove warranty will be void with such an installation.

Do not create a hazard in your home by connecting in

this manner.

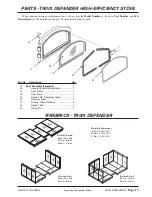

FIREPLACE INSTALLATION

Directly connecting the stovepipe into the existing

masonry chimney (figure 10 “Type A” Fireplace Conver-

sion) of the fireplace is the only approved method of

installation. This is a complicated and involved process

and to insure safety should only by done by a qualified

installer.

1. An entry hole must be cut through the masonry and

tile liner with minimal damage to the liner. At least 8”

of liner must remain below the entry position. When

3. Secure the thimble with refractory mortar. The

thimble should be surrounded by 12” of solid unit

masonry brickwork or 24” of stone.

4. Install the stovepipe into the thimble as far as pos-

sible without extending past the flue lining (see

figures 4 & 6 on pages 6 & 7).

5. A small airspace (about 1/2”) should remain

between the stovepipe and thimble to allow for

expansion of the pipe. Seal this airspace with high-

temperature caulking or ceramic wool.

6. Secure and seal the damper in the closed posi-

tion using high-temp caulking, ceramic wool, or

furnace cement. Also check to see if the chimney

has a cleanout. If it does, make sure it is closed and

sealed as well. A leaky cleanout will greatly reduce

draft efficiency.

If you have any questions regarding venting your

stove, contact the manufacturer or contact the National

Fire Protection Association (NFPA) and request a copy

of the latest editions of NFPA Standard 211 and NFPA

Standard 908. Their address is:

Battery March Park, Quincy, MA 02269.

FIG. 10 - Fireplace Conversion

locating the stove and stovepipe, all

minimum clearances must be ob-

served from combustible surfaces

including mantels, combustible trim-

work, ceilings and walls. Positioning

the center of the stove pipe entry into

the chimney 24” below the ceiling

should insure proper clearance for

a 6” stovepipe.

2. Install a metal or fire clay (5/8” mini-

mum thickness) thimble. Make sure

the thimble is flush with the inner

surface of the chimney liner and does

not protrude into the flue (see figure

4 on page 6).