2

INTRODUCTION

Thank You for your purchase of a Vogelzang Wood/Coal

Burning Gravity Style (Up-Flow) Furnace. Your decision

to buy our Furnace was undoubtedly reached after much

careful thought and consideration. We are very proud you

chose this furnace and trust you will receive the comfort

and economy that others realize when heating with a Vo-

gelzang product.

Your dealer is important in your experience with the fur-

nace not only with the purchase, but for recommendations

for professional installation in your home. The quali

fi

ed

professional installer has been expertly trained in solid-

fuel furnace installation to assure the safety and comfort

for your family while saving you money.

IMPORTANT

Before installing and using your furnace, please read the

following pages thoroughly and carefully. If you follow the

instructions, your furnace will give you safe and more de-

pendable service for years to come.

• First step: Check your local codes. This installation

must comply with their rulings.

• Do Not install this furnace in a mobile home or trailer.•

Always have a smoke or ionization detector and a CO

detector installed in your home.

• To prevent injury or damage, do not allow anyone who

is unfamiliar with the furnace to operate it.

• This furnace must be installed ONLY in the prescribed

manner shown in illustrations 1, 2, or 3 under the In-

stallation Examples in this manual. It is NEVER to be

installed as a counter-

fl

ow or down-draft furnace, or

in any manner wherein the heated air is directed in a

downward

fl

ow into the home or toward to an existing

central furnace.

• NEVER INSTALL outside the home.

• Spend adequate time with your furnace to become well

acquainted with the different settings and how each

will affect its burning patterns. It is impossible to state

just how each setting will affect your furnace because

of the variations in each installation.

DISCLAIMER NOTICE

The BTU ranges and heating capacity speci

fi

cations are

provided as a guide and in no way guarantee the output

or capacity of this unit. The actual BTU output depends

on the type of fuel being burned and its conditions, the

thermostat setting, the draft adjustment and the chimney

to which the unit is attached. The actual area that this unit

will heat depends on factors such as the conditions of the

building, heat loss, type of construction, amount of insu-

lation, type of air movement, the location of the unit and

more importantly the duct work and return air facility.

Warning:

Do not alter this appliance in any way other than speci

fi

ed

in these instructions. Doing so may void your warranty.

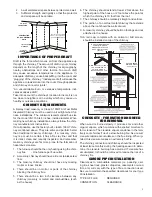

LOCATING YOUR FURNACE

The furnace is to be installed maintaining the clearances

speci

fi

ed in the following illustrations.

Do not place the furnace directly on a combustible

fl

oor. If

you are placing it on a combustible

fl

oor, an approved

fi

re

retardant material, equivalent to 3/8” UL Listed millboard,

measuring 41 x 72 should be placed under the unit. The

material must extend at least 16 inches beyond the front

of the unit and 8 inches on either side of the fuel loading

door opening. It must also extend underneath the chimney

connector and to each side of the connector by at least 2

inches.

CLEARANCES

REDUCED CLEARANCES

NFPA guidelines and most codes permit reduced clear-

ances to combustible walls and ceilings if adequate pro-

tection is added. A common mistake is to assume that

sheet metal, masonry, or millboard placed directly against

a wall protects it. Materials installed in this manner actually

provides very little protection. These materials are good

heat conductors, so they will be almost as hot on their

back side as they are on the exposed side. Therefore, the

combustible wall behind is still a

fi

re hazard.

A wall can be kept cool using these items but only if they

are mounted and spaced out from the wall by an inch or

two to allow free air circulation behind the protective panel.

The protective panel should also have a gap between the

fl

oor and ceiling.

Three rules to follow when constructing wall protectors:

1. Non-combustibility of all materials including mount-

ing and supporting.

22”

12”

20”

15”

COMBUSTIBLE WALL

COMBUSTIBLE WALL

FLUE

(TOP VIEW)

MINIMUM CLEARANCES

TO A COMBUSTIBLE

WALL

CAUTION:

DO NOT store

combustible or

flammable materials or

liquids near the

furnace.