5

reasonably safe and functional installation IF certain stan-

dard procedures are followed. The following are guide-

lines only and are intended to enable the furnace user to

obtain reasonable ef

fi

ciency from his furnace, and with

due respect to safety when installing as a “free-standing

heater”. If installed correctly, and in accordance with the

instructions found in this manual, your warm air furnace

may be installed as a “space heater” within living quarters,

cabins, garage, or workshop. Please adhere to the fol-

lowing:

1. The use of a cold air return and/or

fi

lter box is manda-

tory. This will not only increase your blower life and

provide

fi

ltered air, it will also help prevent the blower

or blowers from “capturing” heated air exiting from the

top of the furnace heat outlets.

2. If installed as purchased, without directing the heat

away from the furnace itself, it will simply sit and cycle,

turning the blowers off and on. The thermostat may

not function properly.

3. All larger furnaces (or those with multi-speed blowers)

absolutely require BACK PRESSURE to prevent pre-

mature motor winding failure. If allowed to operate

at high RPM (As in “FREE AIR” mode - no duct work

or

fl

ow restrictions) the windings overheat, insulation

melts and the motor simply burns up - not covered

under warranty.

CONNECTING HOT AIR DUCT

TO FURNACE

We strongly recommend that the hot air duct work be in-

stalled by a home heating specialist. If doing the installa-

tion yourself, before you decide which installation will best

suit your needs, consult a quali

fi

ed heating technician and

follow his recommendations as to the safest and most ef-

fi

cient method of installation.

The following illustrations are the ONLY acceptable con-

fi

gurations when installed with existing oil or gas furnaces.

INSTALLATION EXAMPLES

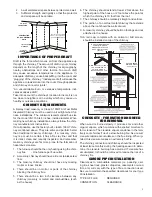

Installation #1

With this installation, a back draft damper (optional) is inserted into

the heat run before the plenum of the existing furnace to prevent

air from the existing furnace to blow back into the furnace when it is

not in use. When a back damper is employed, it should be located

as close to the existing furnace plenum as practical.

INSTALLATION #3

The baf

fl

e on this system should be made the full width of the furnace plenum in

order to properly direct the air into the distribution ducts.

INSTALLATION #2

Extending the hot air duct from the furnace into the existing plenum will

help direct the

fl

ow of air from the furnace as well as the

fl

ow in the existing

furnace. Ducting entering the existing plenum at an angle (approximately

45 degrees) will facilitate air

fl

ow from the furnace while diverting air from

the existing furnace.