Page 8

/

VG820E HEARTWOOD™

VGZ-010 / 20120105.0

DRAFT DAMPER continued . . .

CONNECTOR PIPE INSTALLATION

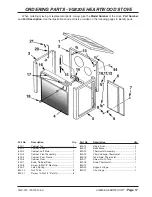

Fig. 7 – Stovepipe/Flue Connections

CORRECT

WRONG

WRONG

Connector pipe is used to make the connection

from the final positioning of your stove to an approved

chimney. Connector pipe is NOT included as part of

the stove. Connector pipe must be 6”/152mm diameter

minimum of 24 MSG (minimum standard gauge) black

or 26 MSG blue steel stove pipe. Connector pipe is not

rated to provide close contact to combustible materi-

als and must have proper clearance from combustible

materials as shown in the clearance diagrams on the

previous pages. Connector pipe should never be used

in place of a chimney. If proper clearances are not ob-

served a house fire could result.

Installation Instructions

1. The crimped end of the stovepipe fits inside the

stove flue collar. Secure with three (3) sheet metal

screws. The first section of connector pipe must be

single walled to properly attach to the stove collar.

Install additional pipe and elbow with the crimped

end towards the stove. This will allow any conden-

sation in the flue to run back into the firebox.

2. Hor izontal pipe r uns must slope upwards

towards the chimney at least 1/4”(6.4mm) per foot

of horizontal run.

3. Yo u m u s t h a v e a t l e a s t 1 8 ˝ / 4 5 7 m m o f

clearance between any horizontal piping and the

ceiling.

4. The pipe cannot extend into the chimney flue

(figure 7).

5. Secure pipe/elbow sections with three sheet metal

screws at each joint to make the piping rigid.

6. It is recommended that no more than two (2)

90° bends be used in the stovepipe installa-

tion. The use of more than two 90° bends may

decrease the amount of draw and possibly

cause smoke spillage. Where possible, use only

corrugated (non adjustable) elbows. These

provide a better seal.

7. The connector pipe must not pass through an

attic or roof space, trusses, closet, or any concealed

space, floor, ceiling, wall, or combustible construc-

tion. (See Chimney Connector Systems & Clear-

ances, page 12.) A UL 103 HT (USA)/ ULC-S629

(CDN) Listed chimney must be used from the first

penetration of ceiling or wall to the chimney cap.

Where passage through a wall or partition of com-

bustible construction is desired, the installation shall

conform to CAN/CSA-B365 (Canada).

WARNING: DO NOT USE A SINGLE-WALL CON-

NECTOR PIPE AS A CHIMNEY! A HOUSE FIRE

COULD RESULT.

NOTE: CONNECTOR PIPE IS

NOT INCLUDED

.

TO PURCHASE, VISIT YOUR LOCAL HARD-

WA R E , H O M E , O R BU I L D I N G C E N T E R .

S E E “ L O C AT I N G S TOV E ” PAG E 6 F O R

ADDITIONAL SPECIFICATIONS.

2. Remove the handle from the damper then slide the

damper into the pipe.

3. Align the damper with the holes drilled in step 1

and insert the handle through the holes and the

damper.

NOTE

: This damper is necessary for the prop-

er operation of the stove and to meet EPA

emissions requirements for heating appli-

ances. It

MUST

be installed before use

.

(NO EXCEPTIONS)