P24AL & P34AL Service Manual

INSTALLING YOUR TUBE-ICE MACHINE

12/2016

3-12

Water Tank Drain.

This valve and connection is for the purpose of flushing and draining the water

tank of impurities, foreign material and cleaning chemicals used during servicing. It should be piped

to an open drain or sump for visible discharge. It can be tied in with the overflow line but no others.

Water Tank Overflow.

A 3” FPT connection on the side of the water tank is provided to carry

away overflow water during the thawing (harvest cycle). This water contains ice fines accumulated

during harvesting and dissolved solids accumulated during the freezing cycle.

Do not reduce the

size of this line

. Three inches is needed to provide sufficient area for ice fines to be flushed out,

especially if the incoming flushing water is 55

F (13

C) or below. This overflow line should not tie

in with any other drain line except the water tank drain.

Unless water quality is superior, do not discharge the overflow water to the cooling tower system.

This water contains additional dissolved solids left from the ice making process and can lead to

excessive condenser fouling or cooling tower chemical usage. It is recommended that a heat

exchanger be used in place of direct contact with condenser water.

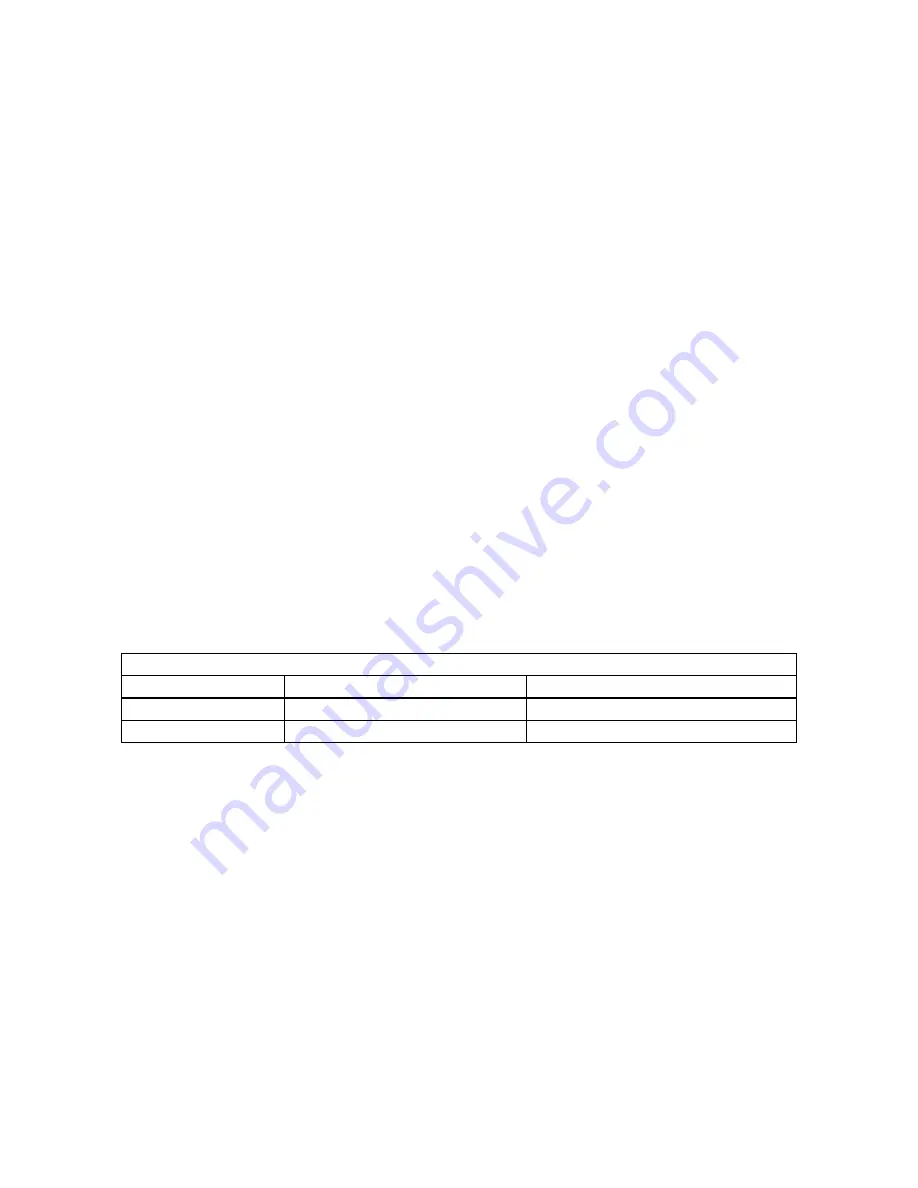

Receiver.

The receiver used to supply hot thaw gas must be sized adequately to provide a sufficient

amount of thawing gas to the freezer. Table 3-2 shows the volume required to hold the refrigeration

charge of the freezer and the hot gas required for the thaw cycle. It is recommended that a heating

coil be installed in the receiver to assure that the liquid ammonia is at saturated temperature at the

start of each thaw period.

Note: Additional storage volume may be required for the interconnecting piping. Add volume of

interconnecting piping to the values shown in Table 3-2

RECEIVER VOLUME (Cubic Feet)

MODEL

With Heating Coil

With out Heating Coil

P24AL

30

45

P34AL

50

70

Table 3-2

Receiver Volume Requirements

Thaw Gas Pressure Regulator.

The thaw gas pressure regulator is a 2” solenoid operated pressure

combination regulator and shut-off valve (see Figures 1-2 and 1-5 for locations).

Do not reduce the

size of this line

. This valve is designed to carry the proper amount of thaw gas to the evaporator

during the harvest cycle. See Page 5-7 for operating instructions.

Suction Pressure Regulator.

When a P24AL or P34AL is attached to a central system, a pressure

regulator will be required (see Figures 3-15 through 3-16 for location). This regulator (usually

furnished by the purchaser) must be a combination back pressure regulating and stop-type valve.

The usual minimum pressure drop across this type valve is 2 psig; therefore, the valve must be set to

maintain a freezer pressure that is at least 2 psi above the maximum general suction pressure.

Compressor Unloading.

When a P24AL or P34AL is attached to a dedicated compressor system,

unloading of the compressor will be required. A minimum compressor unloading during the harvest

Summary of Contents for P-24AL

Page 1: ...12 2016 P 24AL P 34AL TUBE ICE MACHINE Service Manual 5000 ...

Page 10: ...P24AL P34AL Service Manual TABLE OF CONTENTS 12 2016 vi ...

Page 15: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 5 Figure 1 2 P24AL Right Side ...

Page 16: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 6 Figure 1 3 P24AL Back Side ...

Page 17: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 7 Figure 1 4 P24AL Left Side ...

Page 18: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 8 Figure 1 5 P34AL Front Side Control Panel ...

Page 19: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 9 Figure 1 6 P34AL Right Side ...

Page 20: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 10 Figure 1 7 P34AL Back Side ...

Page 21: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 11 Figure 1 8 P34AL Left Side ...

Page 22: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 12 ...

Page 62: ...P24AL P34AL Service Manual START UP OPERATION 12 2016 5 8 ...

Page 84: ...P24A P34A Service Manual TROUBLESHOOTING 12 2016 8 12 ...

Page 110: ...P24AL P34AL Service Manual SERVICING OPERATIONS 12 2016 9 26 ...

Page 126: ...P24AL P34AL Service Manual TABLES CHARTS 12 16 16 11 8 ...

Page 130: ...P24AL P34AL Service Manual INDEX 12 2016 12 4 ...

Page 131: ...Appendix A ...

Page 134: ......

Page 136: ...i ...

Page 137: ...ii ...

Page 138: ...1 ...

Page 139: ...2 ...

Page 140: ...3 ...

Page 141: ...4 ...

Page 142: ...5 ...

Page 143: ...6 ...

Page 144: ...7 ...

Page 145: ...8 ...

Page 146: ...9 ...

Page 147: ...10 ...

Page 148: ...11 ...