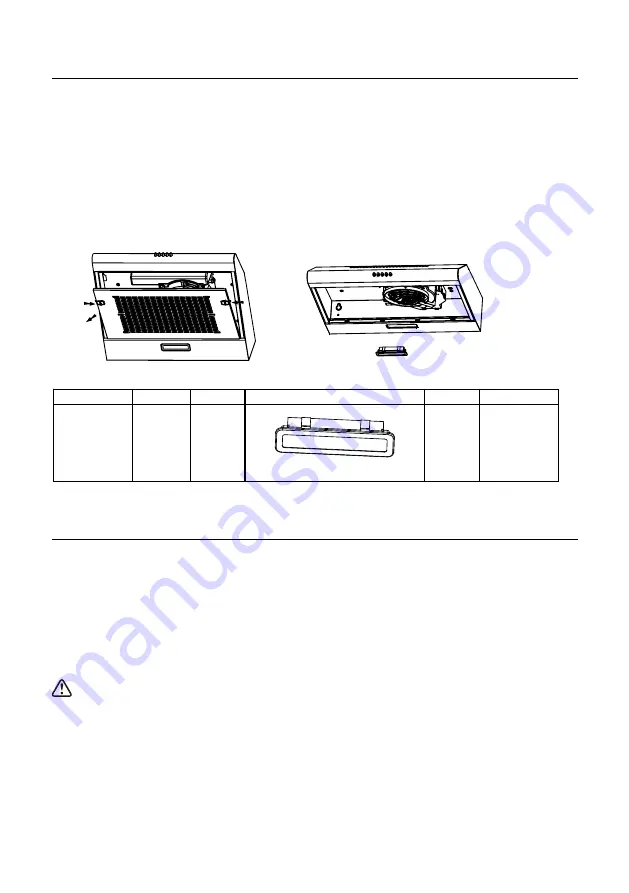

LIGHTING

LIGHT REPLACEMENT

Switch o

ff

the extractor hood and isolate the extractor hood by pulling out the

mains plug or switching o

ff

the fuse.

Remove the grease filter.

Remove the light by levering its fitting from the hood body (this may require

pressure or force to be applied).

Disconnect the connector of the light.

Replace the light with a new one of the same type,making sure that you

connect the light with the light cable correctly.

Reconnect the power by inserting the mains plug or by switching on the fuse.

CLEANING AND MAINTENANCE

Disconnect range hood from power supply before cleaning or servicing.

Cleaning the surface of hood frequently. Use mild soap or detergent to clean the hood.

Do not use harsh alkalis or abrasives

.

Avoid the use of scouring powers or dishwasher compounds.

Grease filter may be washed using mild soap or detergent. (Heavy grease build-up may

not be cleaned easily and the filter may require replacement).

Charcoal filter cannot be cleaned and must be replaced regularly.

Information

Cleaning water must not inter into motor, control switch etc. electrical parts.

It is recommendable to clean the metallic filter every three months by carrying out the following

instruction:

Remove the metallic filter from the cooker hood and wash it in asolution of water and neutral

liquid detergent, leaving to soak.

Rinse thoroughly with warm water and leave to dry.

The metallic filter may alter in color after several washes. This is notcause for customer

complaint or replacement of metallic filter.

LED modules,

separete ballast

DSH-1.5-

S-33.2/120

Max power Voltage

Picture

Lamp Cap

ILCOS D code

1.5W

Square/Diameter:33.2mmx120mm

220-240V

9