23

6.17

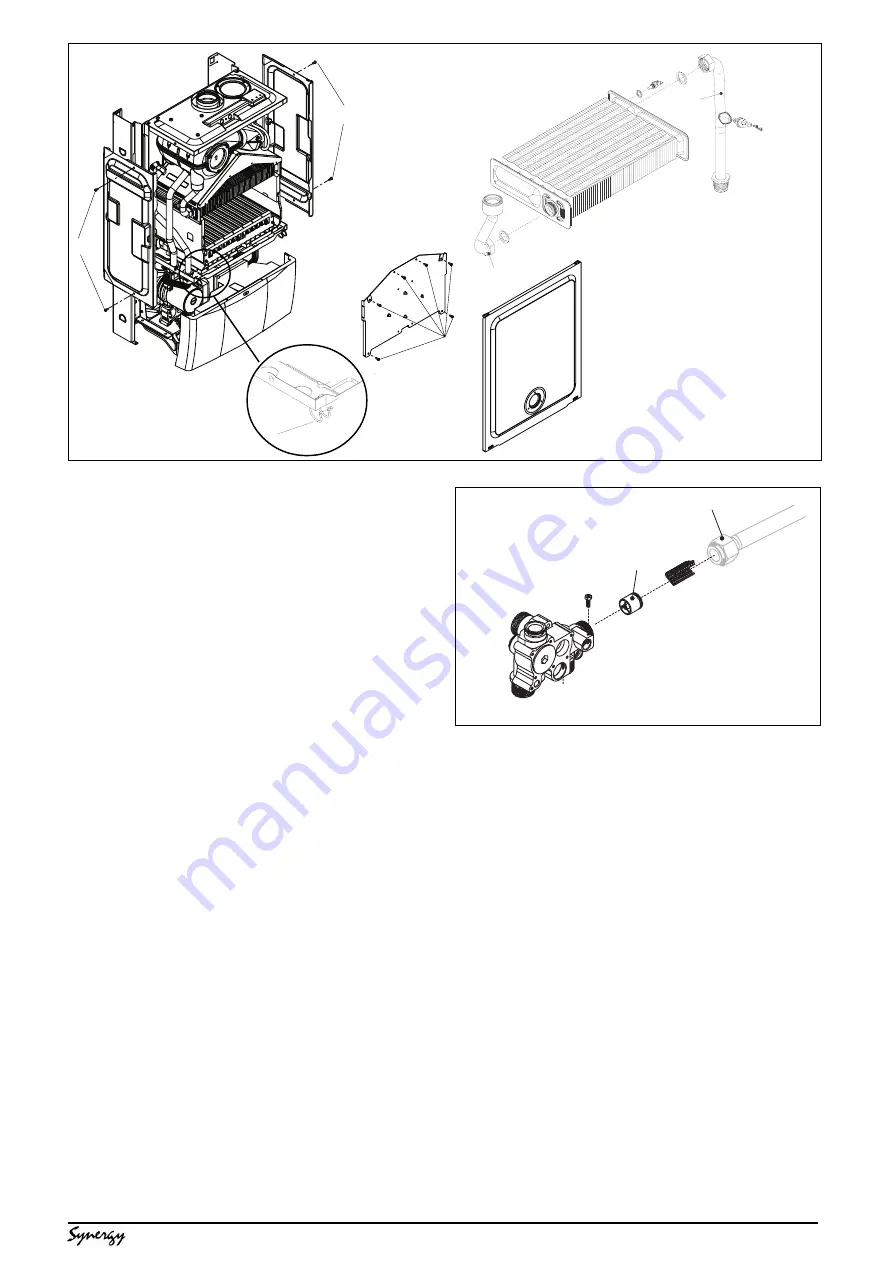

MAIN HEAT EXCHANGER (see fig. 27 & 29)

Carry out component removal procedure as

described in 6.4.

Fig. 27: unclip and remove the air chamber cover,

gently pull the cover towards you before lifting

and disengaging (2). Locate and remove the six

screws that secure the front combustion cover,

then remove the cover (3).

Fig. 29: remove the air chamber side panels if

necessary by unscrewing the securing screws

(3). Disconnect the flow and return connections

(4, 5) on the heat exchanger. The heat exchanger

can now be withdrawn from the appliance.

Replace in the reverse order. Ensure all seals

are in good condition, taking care to ensure they

are replaced correctly.

6.18

AIR PRESSURE SWITCH (see fig. 27 & 28)

Carry out component removal procedure as

described in 6.4.

Fig. 27: unclip and remove the air chamber cover,

gently pull the cover towards you before lifting

and disengaging (2).

Fig. 28: locate and remove the two screws (6)

holding the air pressure switch to the air chamber.

Disconnect the electrical connections and silicone

tubes (10) attached to the air pressure switch,

noting their positions. Replace in the reverse

order. Ensure all seals are in good condition,

taking care to ensure they are replaced correctly.

6.19

AUTOMATIC BYPASS (see fig. 30)

Carry out component removal procedure as

described in 6.4.

Disconnect and remove the flow pipe at the

heating manifold (1) and at the connection to the

air chamber. Using a hooked piece of wire,

carefully withdraw the bypass cartridge (2).

Ensure all seals are in good condition, taking care

to ensure they are replaced correctly. Replace in

the reverse order ensuring the cartridge is facing

the correct way.

Fig. 29

3

2

2

1

5

4

3

5

4

6.20

EXPANSION VESSEL fig. 1

Should the removal and replacement of the

expansion vessel be deemed impractical, an

external expansion vessel may be fitted to the

return pipe as close to the appliance as possible.

6.20.1 EXPANSION VESSEL REMOVAL (with

sufficient clearance above)

Carry out component removal procedure as

described in 6.4. Disconnect the flue from the

appliance. Disconnect the flexible expansion pipe

from the vessel (fig. 31). Locate and remove the

four screws that secure the vessel top holding

plate, remove the plate. The expansion vessel

can now be removed. Replace in the reverse

order. Ensure all seals are in good condition,

taking care to ensure they are replaced correctly.

6.20.2 EXPANSION VESSEL REMOVAL (with

insufficient clearance above)

Carry out component removal procedure as

described in 6.4. Disconnect the flue elbow or

pipe from the appliance flue outlet. Unclip and

remove the air chamber cover, gently pull the

cover towards you before lifting and disengaging.

Remove the RH side panel of the air chamber.

Disconnect the wiring to the fan, pressure switch,

primary thermistor & overheat thermostat.

2

1

Fig. 30