ICV08

13

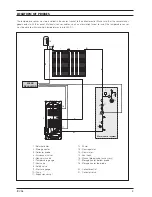

FILLING THE CIRCUIT

Bleeding

Bleed the circuit:

- On start-up (after initial filling) (see the figure on page

10).

- Whenever necessary, as in the event of system

malfunctioning.

Make quite sure that all air has been bled out of the

system.

b

Risk of burns from hot fluid inside the collectors!

b

Only open the vent valve if the temperature of the

fluid in the circuit is below 60°C.

Make sure that the collectors are not hot before

you start bleeding the circuit. Always cover the

solar collectors before bleeding the circuit. Always

perform bleeding in the morning.

Checking the heat transfer liquid

Check the anti-freeze effect and the pH level of the heat

transfer liquid every 2 years.

- Use an instrument like a refractometer or densimeter

to check the anti-freeze effect (which must have a

nominal protection value of approx. -30°C). If the

protection threshold is higher than -26°C, replace the

mix, or add anti-freeze as required.

- Use litmus paper to check the pH (nominal value

approx. 7.5). If the measured value is below 7, change

the mix.

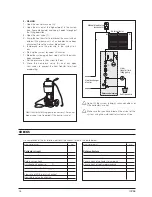

Perform the following steps before starting up the system.

1 - FLUSHING AND SEAL TESTING THE SYSTEM

If copper piping has been used and joints have been hot brazed, flush out the system to remove any brazing residues.

Seal test the system after you have flushed it out.

b

Fill the solar collector with glycol/water mix immediately after flushing it out, because flushing water may remain

trapped in the circuit (with a consequent risk of freezing).

2 - PREMIXING WATER + GLYCOL

Glycol anti-freeze is supplied separately in standard

volumes and must be premixed with water in a suitable

container before being used to fill the system. For

example, a mix of 40% glycol and 60% water provides

anti-freeze protection down to a temperature of -21°C.

b

The propylene glycol supplied is specially

formulated for solar collector applications and

remains fully efficient throughout the -32 to +180°C

temperature range.

I t i s a l s o n o n - t o x i c , b i o d e g r a d a b l e a n d

biocompatible.

b

Do NOT part fill the circuit with pure glycol then

add water later.

b

Do not use automatic or manual filling systems.

b

If the water supply is highly chlorinated, use distilled

water to prepare the glycol/water mix.

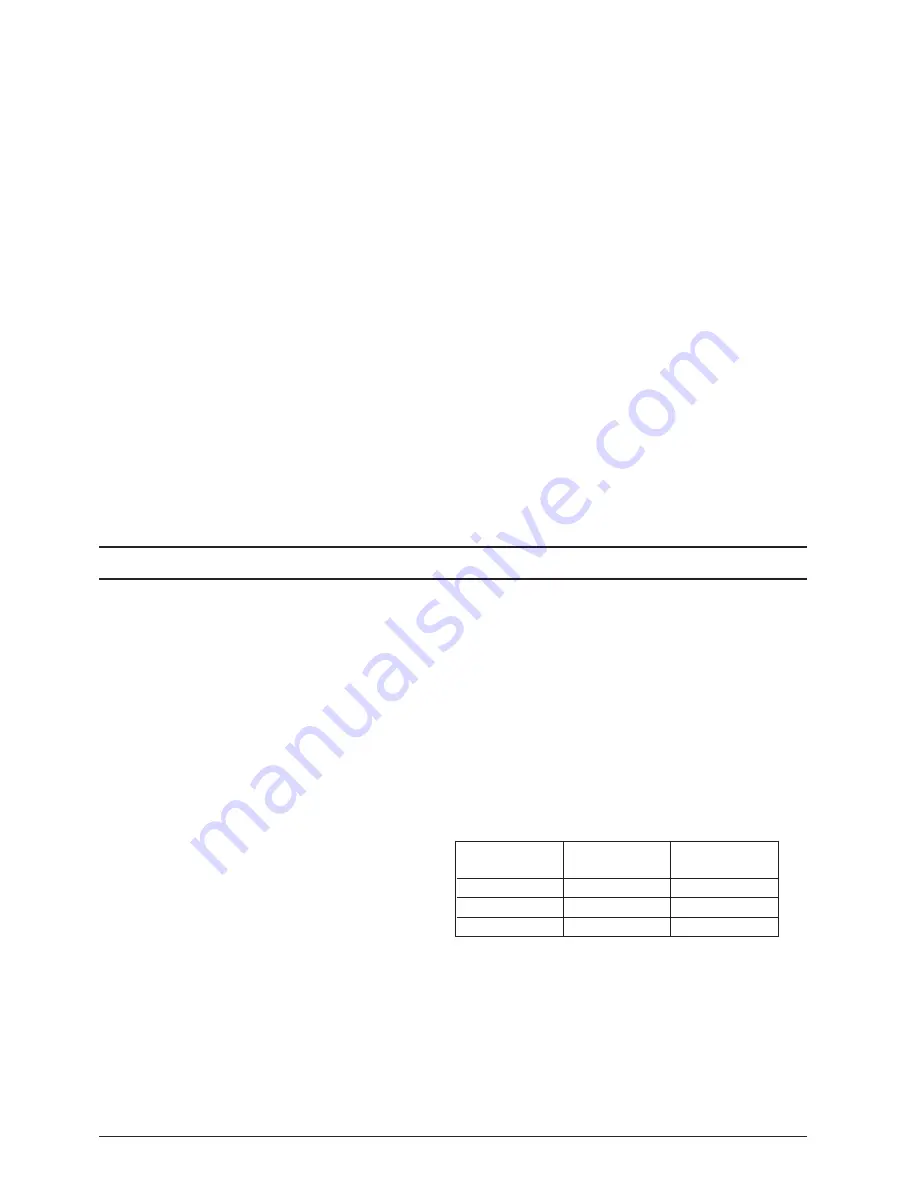

Anti-freeze

50%

40%

30%

-32°C

-21°C

-13°C

1,045 kg/dm

3

1,037 kg/dm

3

1,029 kg/dm

3

Temperature

Density

Summary of Contents for ZENITH INSET

Page 15: ......