ICV08

7

TECHNICAL SPECIFICATIONS

ACCESSORIES

1

0,8

0,6

0,4

0,2

0

0

0,02

0,04

0,06

0,08

0,1

0,12

Tm[m

2

K/W]

*

Total area

2,52 m

2

Exposed area

2,32 m

2

Effective absorption area

2,28

m

2

Connections (F) – (F)

1”

Empty weight

54 kg

Liquid content

1,70 l

Recommended flow rate per m

2

of panel

30

l/h

Glass type - thickness

safety glass with anti-reflective surface - 4 mm

Absorption (

α

) ~

0,95

%

Emissions (

ε

) ~

0,05

%

Maximum permitted pressure

10

bar

Maximum temperature

230

°C

Maximum number of collectors connectable in series

6

n°

DESCRIPTION

ACCESSORY

CODE

kit basic inset colletctor TL

20001441

kit basic cover inset collector TL

20001442

kit additional cover inset collector TL

20001444

kit additional inset collector TL

20001443

The following accessories are available, to be ordered separately.

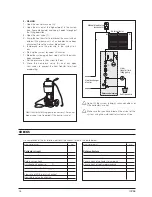

Efficiency curve

Tested according to EN 12975, referred to a

33.3% water-glycol mix, flow rate of 300 l/h,

and irradiation G = 800W/m

2

.

Tm = (Coll._inlet _temp. + Coll._outlet_

temp.)/2

T*m

= (Tm - ambient_temp)/G

Optical

efficiency of

absorber

(

η

ο

)

0,806

3,68

0.0072

Thermal dispersion factor

of absorber

a1

W/(m

2

K)

a2

W/(m

2

K

2

)

Diameter of connection pipes for a specific flow rate of 30 litri/m

2

h

Total surface area (m

2

)

approx. 5

approx. 7,5

approx. 12,5

Diameter of copper pipe (mm)

10-12

15

18

Diameter of steel pipe

DN16

DN20

Summary of Contents for ZENITH INSET

Page 15: ......