O

peratOr

’

s

M

anual

2

ENGLISH

i

nStallation

c

learance

r

equirementS

The minimum clearance is 6 inches (15 cm) on all sides of the machine and

30 inches (76.2 cm) inches above the machine.

Ambient temperature must be between 41-86 °F (5-30 °C). Never locate the

machine near a heat source. This can damage the lid.

1. Remove all packing material and tape, as well as any protective plastic

from the equipment.

2. Clean any glue residue left by the plastic or tape.

3.

Place the vacuum pack machine on a flat, level surface.

4. Check the oil gauge window at the back of the machine. Verify the oil

level is between the minimum and maximum fill lines.

NOTICE: Running the machine without oil or insufficient oil will

damage the machine and void the warranty.

5. Plug the power cord into a grounded electrical outlet that matches the

nameplate rated voltage.

NOTICE: Using a voltage other than the nameplate rated voltage will

cause damage to the unit. Incorrect voltage, modification

to the power cord or electrical components can damage

the unit and will void the warranty.

6. Run the Pump Conditioning program. See “Pump Conditioning program”

on page 4 in this manual.

o

verview

a

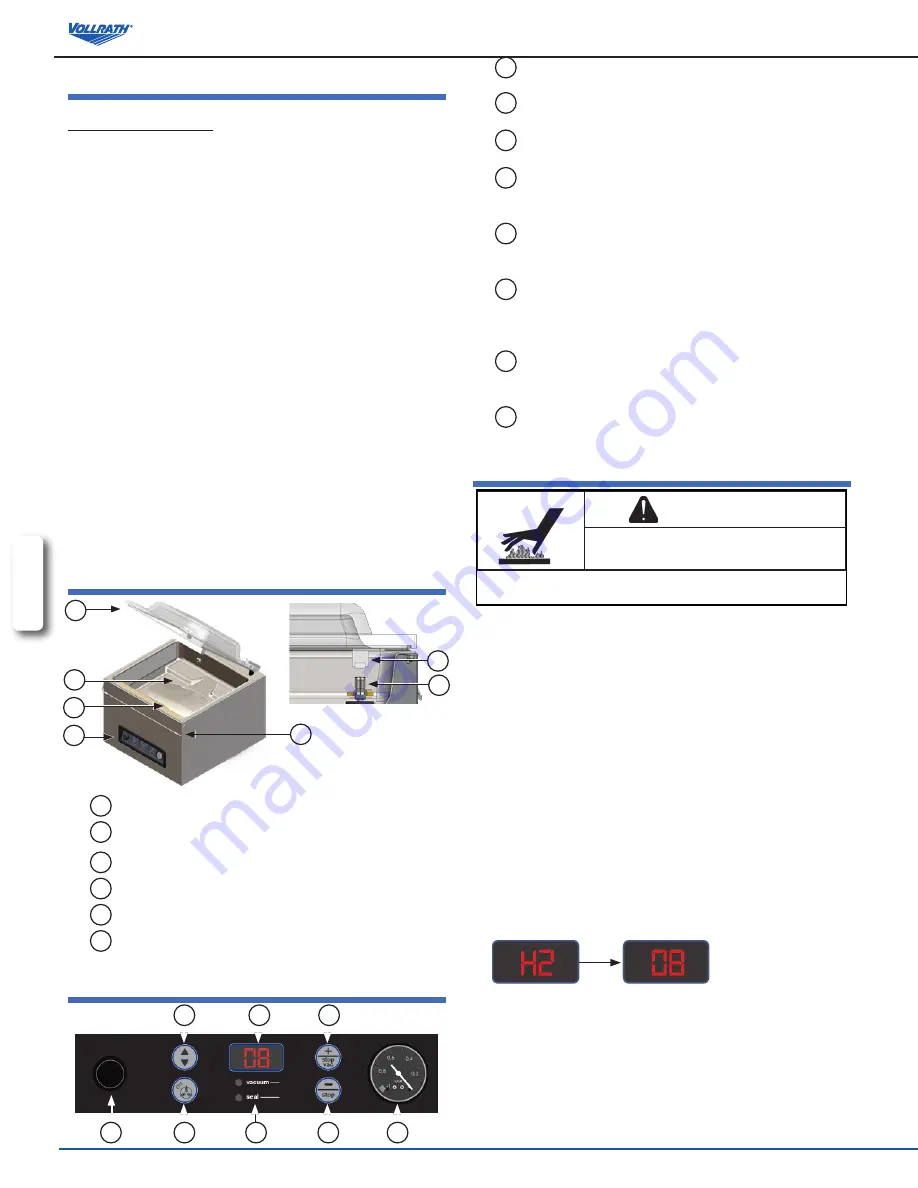

B

D

c

e

c

F

a

Lid -

Seals the chamber during the vacuum cycle

B

Chamber -

Products are placed in the chamber with the

opening of the vacuum seal bag laid over the seal bar

c

Seal Bar -

Seals the vacuum bag

D

Control Panel -

Selects and programs functions

e

Seal Pad -

Provides counter-pressure on the sealing bar

F

Lid Retainer -

Holds lid closed when machine is not in use.

c

ontrol

P

anel

B

a

c

e

g

h

D

F

a

On/Off Button -

Turns the machine On and Off.

B

Function Select Button -

Selects vacuum or seal functions.

c

Oil Cleaning Program Button -

Activates the pump cleaning

program.

D

Display -

Shows the current value of the active function during

the program cycle or the set value of the selected function

when the machine is idle

e

Function LEDs -

The LED for the function illuminates when

the function is active during the program cycle or when the

function is selected in the programming mode.

F

Increase Time / Vacuum Stop Button -

During a packing

cycle, stops the current function and continues to the next step

in the program. In programming mode, increases the time of

the selected function.

g

Decrease Time / Stop Button -

During a packing cycle,

interrupts all functions and cancels the cycle. In programming

mode, decreases the time of the selected function.

h

Vacuum Gauge -

Shows the pressure value in the vacuum

chamber. A value of -1 bar is the equivalent of 99% vacuum.

o

Peration

cautiOn

Do not touch the sealing bar when placing vacuum bags in the

chamber

Burn Hazard.

Sealing bar may become hot after repeated use.

NOTICE: Never pack products that can be damaged by vacuum

packaging.

Avoid packing warm products to reduce condensation and

corrosion risks for the pump.

Special instructions apply for packing liquid products. See

“Packing Liquid Products” on page 3.

The machine is designed for a maximum use of 5 hours per

day.

This machine is not designed for continuous use. Allow 15

seconds between packing cycles. Do not exceed a vacuum

time of 60 seconds.

If the machine has been in use for one hour, stop the

machine and allow it to cool to ambient temperature.

The machine must be moved or transported in an upright

position. The machine may NOT be tilted because this can

cause damage to the pump.

1. Press the power button to turn on the machine. The display shows codes

for the software revision. For example:

2. If the machine has not been used for a while, run the Pump Conditioning

Program. See “Pump Conditioning program” on page 4.

3. Place food product in a vacuum sealing bag.