Item No. 26131-1

Rev 2/23/15

www.vollrath.com

The Vollrath Company, L.L.C.

1236 North 18th Street

Sheboygan, WI 53081-3201

U.S.A.

Main Tel: 800.628.0830

Fax: 800.752.5620

Technical Services: 800.628.0832

Service Fax: 920.459.5462

Canada Service: 800.695.8560

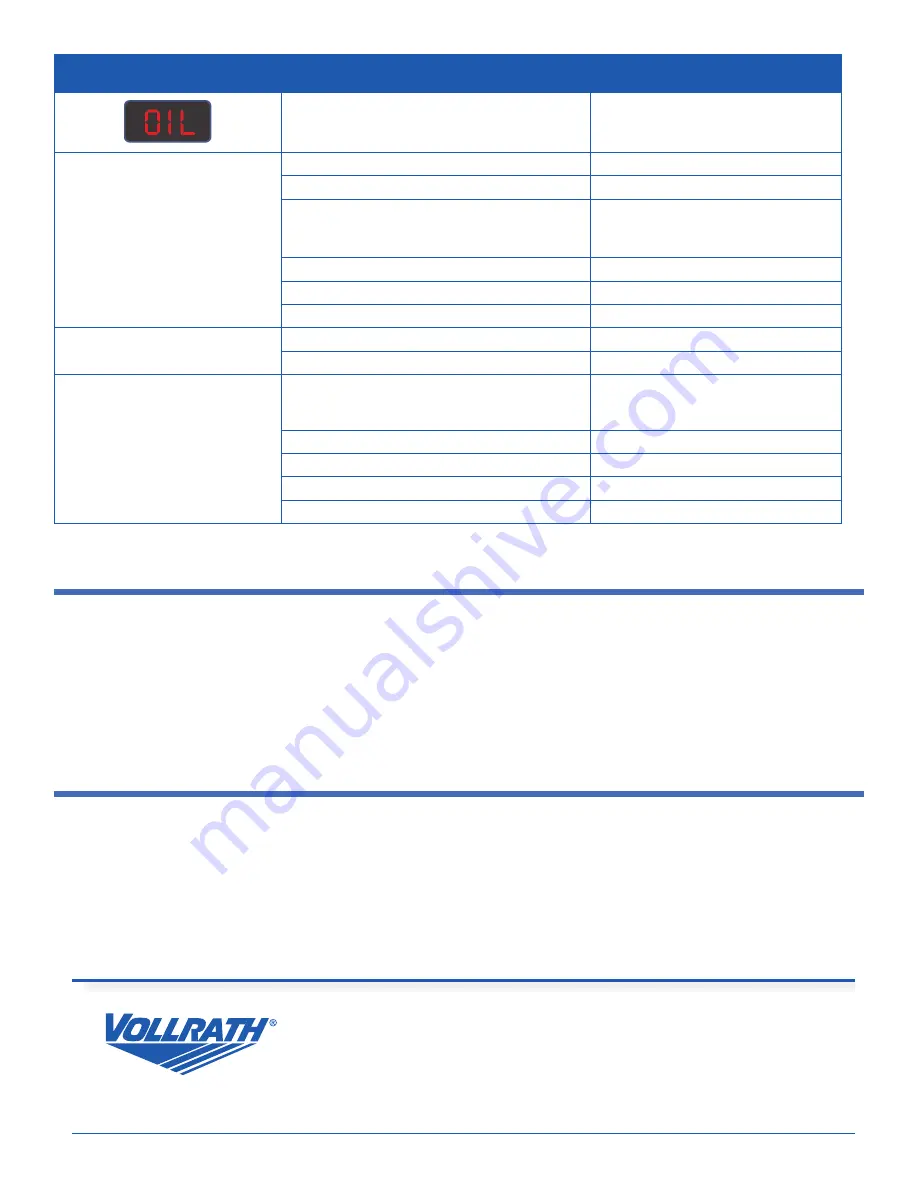

Problem

it might Be caused By

course of action

The machine use has reached a scheduled oil change.

Contact Vollrath Technical Services.

Final vacuum is not sufficient.

The set vacuum time is too short.

Extend the vacuum time.

There is too little oil in the vacuum pump.

Contact Vollrath Technical Services.

The extraction hole at the back of the vacuum chamber is

partially covered by the vacuum bag during extraction.

Place the vacuum bag closer to the sealing bar.

The lid gasket is worn.

Replace the lid gasket.

The oil is contaminated.

Contact Vollrath Technical Services.

The oil exhaust filter is saturated.

Contact Vollrath Technical Services.

The machine extracts air too slowly.

The oil exhaust filter is saturated.

Contact Vollrath Technical Services.

The pump’s extraction filter is blocked.

Contact Vollrath Technical Services.

Vacuum bag is not sealed correctly.

The vacuum bag is being placed incorrectly on the sealing

bar.

Place the vacuum bag neatly and smoothly on

the sealing bar. Ensure that the opening of the

bag is always within the vacuum chamber.

The sealing time is too long or too short.

Adjust the sealing time longer or shorter.

The seal pad under the lid is damaged or worn.

Replace the seal pad.

The Teflon tape is damaged.

Replace the Teflon tape.

The vacuum bag opening is not clean.

Clean the vacuum bag’s opening.

S

ervice

and

r

ePair

There are no user serviceable parts within this appliance. To avoid serious injury or damage, never attempt to repair the unit or replace a damaged power cord

yourself. Do not send units directly to The Vollrath Company LLC. Please contact Vollrath Technical Service from the list below.

VOLLRATH Technical Service • 1-800-628-0832 • Email: techservicereps@vollrathco.com

When contacting Vollrath Technical Service, please be ready with the item number, model number (if applicable), serial number, and proof of purchase showing the

date the unit was purchased.

w

arranty

S

tatement

for

t

he

v

ollrath

c

o

. l.l.c.

The Vacuum Packing Machine with 12" Sealing Bar has a 2 year warranty.

This warranty does not apply to products purchased for personal, family or household use, and The Vollrath Company LLC does not offer a written warranty to

purchasers for such uses.

The Vollrath Company LLC warrants the products it manufactures or distributes against defects in materials and workmanship for a period of one year, except as

specifically described in our full warranty statement. In all cases, the warranty runs from the date of the end user’s original purchase date found on the receipt. Any

damages from improper use, abuse, modification or damage resulting from improper packaging during return shipment for warranty repair will not be covered under

warranty.

For complete warranty information, product registration and new product announcement, visit www.vollrath.com.