8

Vacuum Packing Machine with Dual 16" Sealing Bars and Advanced Control System (ACS) Operator’s Manual

MAINTENANCE

NOTICE: The machine must be moved or transported in an upright

position.

NOTICE: Do NOT tilt the machine. Tilting could enable oil to flow out

of the pump and cause damage to the machine.

The following maintenance schedule is only a guideline. Actual

maintenance needs will vary depending on machine use. Inspect your

machine regularly.

Replace the Sealing Wires and Teflon

®

Tape

Check the sealing bar for damage. Replace the Teflon tape or sealing

wires if the seal quality is no longer sufficient or if the Teflon tape or

seal wires are worn.

Tools Needed:

• Phillips screwdriver

• Tensioning tool or pliers

• Scissors

• Lint-free cleaning cloth

• Replacement Teflon tape

• Replacement sealing wire

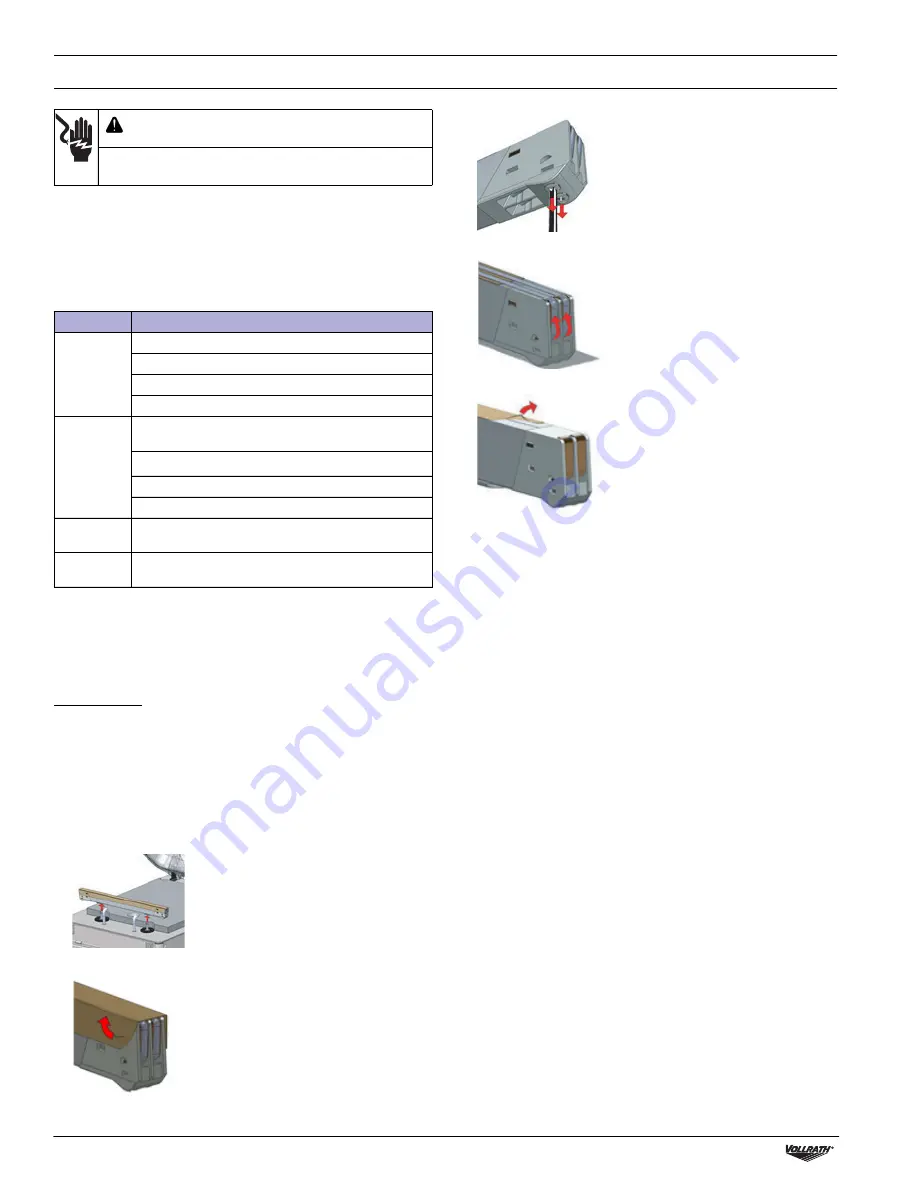

1. Pull up on the sealing bar to remove it from the machine.

2. Remove the Teflon tape that protects the sealing wires.

3. Remove the screws on the bottom side of the seal bar.

4. Remove the sealing wires.

5. Remove the Teflon tape from the sealing bar.

6. Clean the sealing bar with a lint-free cloth.

WARNING

Electrical Shock Hazard

Unplug unit before servicing.

Interval

Procedure

Weekly

Check the oil by viewing the Oil Inspection Window.

Inspect the seal bar for wear.

Inspect the seal pad under the lid for wear.

Inspect the lid gasket and lid.

Every six

months

Replace the oil in the vacuum pump. Contact Vollrath

Technical Services.

Replace the sealing wires and Teflon

®

tape.

Replace the seal pad under the lid.

Replace the lid gasket.

Yearly

Inspect the oil exhaust filter. Contact Vollrath Technical

Services.

Every four

years

Replace the lid, gas springs and seal cylinder

membranes. Contact Vollrath Technical Services.