34

The following procedures are performed less

frequently than daily or as needed.

NOTE:

YOUR HANDS SHOULD BE CLEANED

AND SANITIZED BEFORE YOU PERFORM

THE FOLLOWING PROCEDURES.

NOTE:

THE FOLLOWING PROCEDURES

REQUIRE APPROVED, SERVICEABLE AND

SANITIZED TOOLS AND BRUSHES.

CONTACT WHITE GLOVE SERVICE FOR

RECOMMENDED SUPPLIES.

NOTE:

USE FLO-SAN® SANITIZER, STERA-

SHEEN® GREEN LABEL SANITIZER, AND

DAWN® DISH SOAP MIXED WITH WARM

WATER (108°F / 42°C) FOR THE FOLLOWING

PROCEDURES. REFER TO

MANUFACTURER’S INSTRUCTIONS FOR

PROPER PREPARATIONS OF THESE

CLEANING AGENTS.

NOTE:

INSPECT ALL WEAR ITEMS AND

REPLACE IF NECESSARY.

NOTE:

OPERATE UNIT UNDER NORMAL

AMBIENT TEMPERATURES BETWEEN 60

AND 80 DEGREES FAHRENHEIT. UNIT

SHOULD NEVER BE EXPOSED TO

FREEZING TEMPERATURES.

Clean-In-Place (CIP) Procedure

The Clean-In-Place procedure should be

performed every 30 days to ensure that the

syrup passageways are free of any product

crystallization. The medium used for this

process must be the approved sanitizing

products Flo-San® and Stera-Sheen® Green

Label mixed according to the product

manufacturer’s instructions. This Clean-In-

Place procedure is detailed in four phases:

(1) Prep

(2) Flush

(3) Clean

(4) Reassemble

To ensure maximum results, the following

instructions should be completed in sequence

as stated. This will expose the system and

parts to the sanitizing medium for about 130

minutes.

CIP - Phase 1: Prep

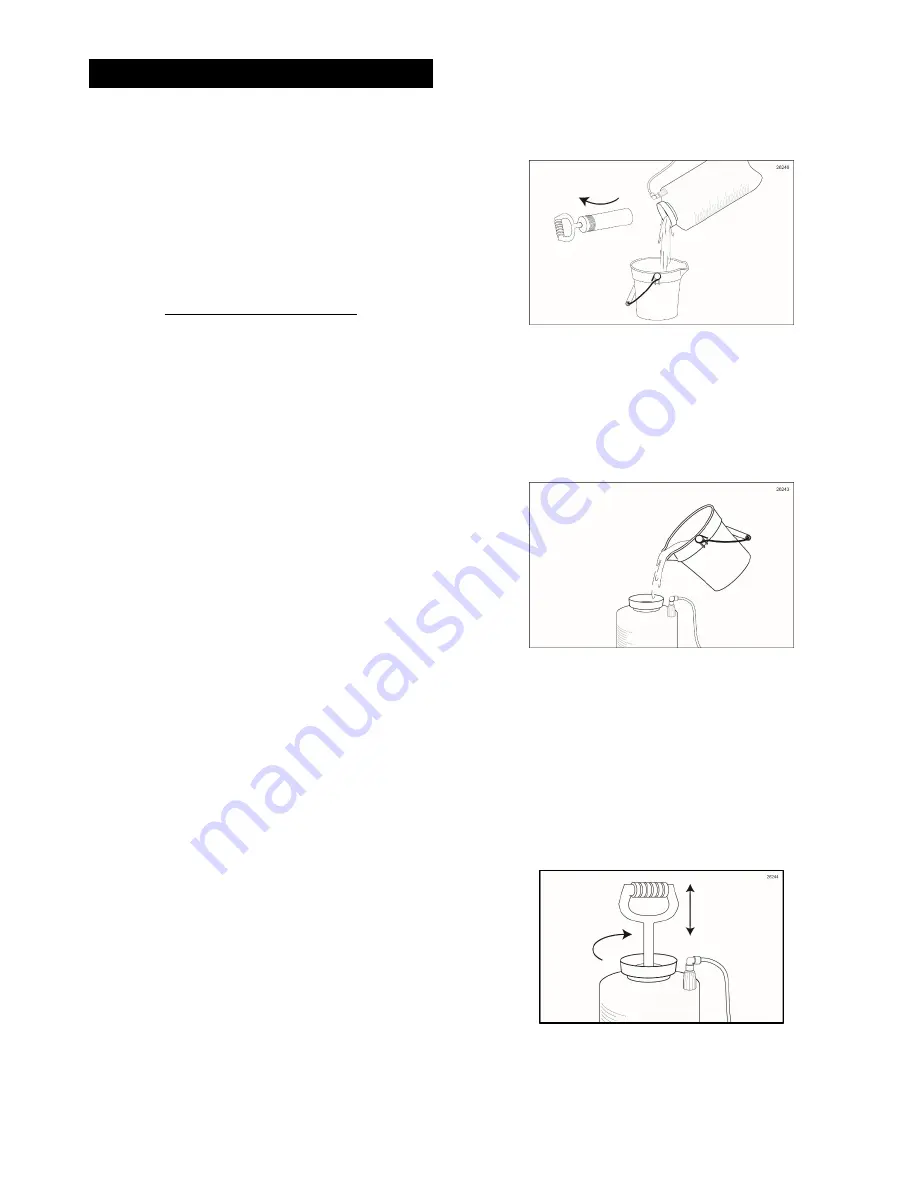

1. Remove the sanitizer tank’s hand pump and

discard any remaining Flo-San sanitizer

solution. Rinse out the tank with water.

2. Mix two packets (4 oz total) of Stera-

Sheen® Green Label with four gallons of

warm water (108°F / 42°C) until dissolved.

Fill the sanitizer tank to the top fill line.

Pour approximately 16 oz. of sanitizer

solution into a spray bottle and set aside the

rest for sanitizing parts in Step 17.

NOTE:

IF YOUR TANK RUNS OUT OF

SOLUTION DURING THE CIP PROCESS,

REFILL IT USING THE EXCESS STERA-

SHEEN SOLUTION OR MIX A NEW BATCH

USING HALF A PACKET OF STERA-SHEEN

AND 1 GALLON OF WARM-HOT WATER.

3. Reinstall the hand pump and tighten

sufficiently. Using the handle, pump air into

the sanitizer tank to prime the pump

(approximately 10 strokes.)

NOTE:

NO PRESSURE IS NEEDED IN THE

TANK DURING NORMAL OPERATIONS.

SCHEDULED MAINTENANCE

Summary of Contents for STL-80SS

Page 2: ......

Page 9: ...6 PAGE INTENTIONALLY LEFT BLANK ...

Page 11: ...8 General System Overview Figure 1 ...

Page 13: ...10 Cabinet Continued Figure 2 ...

Page 17: ...14 Syrup Pump and Related Parts Figure 4 ...

Page 19: ...16 Sanitizer Pump and Related Parts Figure 5 ...

Page 23: ...20 Spare Parts Kit Figure 7 ...

Page 24: ...21 PAGE INTENTIONALLY LEFT BLANK ...

Page 36: ...33 PAGE INTENTIONALLY LEFT BLANK ...

Page 50: ...47 PAGE INTENTIONALLY LEFT BLANK ...

Page 73: ......

Page 74: ......