User manual - VOLUMAIR HV230 - HV240

201607-177A-ENG

P10

5. USE OF THE SPRAY-GUN

5.1. PREREQUISITES

Before each use, atomize some water before using the paint to be sprayed.

Spray-gun setting

•

It is possible to give the paint jet a horizontal or vertical shape. To do so, turn the diffuser head (2a).

•

Turn the thumwheel (4) to increase or decrease the paint flow-rate.

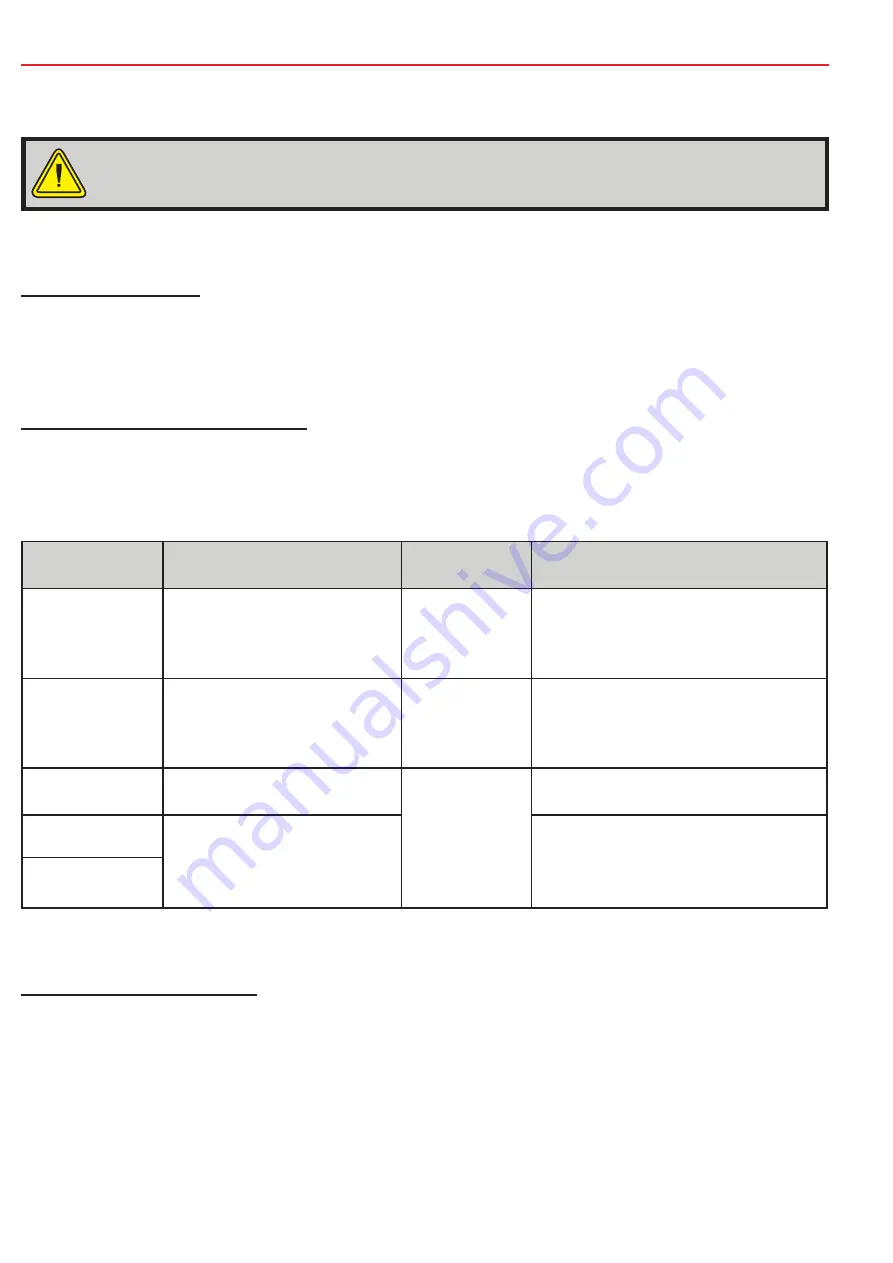

Choice of the atomization kit

The spray-gun can be equipped with 5 different jet nozzles.

Choosing the right atomization kit is essential to obtain a perfect finish. This choice has to be made

according to the work to be done, the kind of paint, the dimensions of the objects and surfaces to be

covered (see table below).

Nozzle

diameter

Work to be made

Viscosity

Product to be used

0,50 mm

Finishing jobs, low output,

small areas, decoration,

refinishing, shadow, stain,

etc...

15 seconds

Light, thin, chromate products,

etc...

1 mm

All kind of varnish jobs,

house-hold appliances,

furniture, car bodywork,

aviation, etc...

26 seconds

All products with normal dilution,

lac-quer, varnish, oil based,

cellulosic, polyu-rethane, etc...

1,50 mm

For usual jobs, high output,

large areas

+30 seconds

Bottom layer, primer, oil based

paints, dispersion, etc...

2,50 mm

Thick layer, high output,

large areas, speckled,

decorative ef-fects, building,

insulation, etc...

Glues, heavy products, minium,

gelcoat, oilbased varnish, etc...

3,50 mm

Use of the viscosimeter

•

The final result mostly depends on the paint preparation, verify the viscosity with the viscosimeter

or make a try with the spray-gun.

•

Dilute a part of the paint with the appropriate thinner.

•

Fill the viscosimeter to the top and let the liquid flow and monitor the time it takes until the trickle of

paint becomes discontinuous.

•

Use the table above to verify if the time corresponds to product used.

•

If the time is longer, increase the dilution, if the time is shorter, add more paint