202005-418-ENG

User manual - Eole T5 + HV460

P11

4. USE OF THE MACHINE (continued)

4.2. ATOMIZATION

1. Prepare the surface to be painted (sanding, cleaning, etc...).

2.

Fill the bowl with paint (around 3/4 of the bowl). For more ease, put the bowl onto the (H) support.

3. Mount the spray-gun body onto the spray-gun.

4. Connect the hose on the (I) coupling on the turbine side and the (D) coupling on the spray-gun side.

5.

Connect the turbine electrically and press the switch (J).

6. For an optimal atomization, hold the spray-gun as horizontal a possible. The paint jet has to be

perpendicular to the surface to be painted, with a distance of about 20 cm.

7. Proceed by crossed sections, horizontal and vertical, directing the diffuser head as needed.

8.

Move the spray-gun with an uniform movement and a regular speed. Release the trigger at the end

of each section.

9. To avoid bleeding, press the trigger only after having begun the movement of the spray-gun.

10. Do not try to cover everything in one layer, prefer applying a second one.

During utlization, use the potentiometer (K) to increase or decrease the air flow-rate into the

turbine.

So that the paint is at the ideal viscosity, use the viscosimeter delivered with the turbine.

Dilute a part of the paint with the appropriate thinner.

Fill the viscosimeter to the top and let the liquid flow and monitor the time it takes until the trickle

of paint becomes discontinuous.

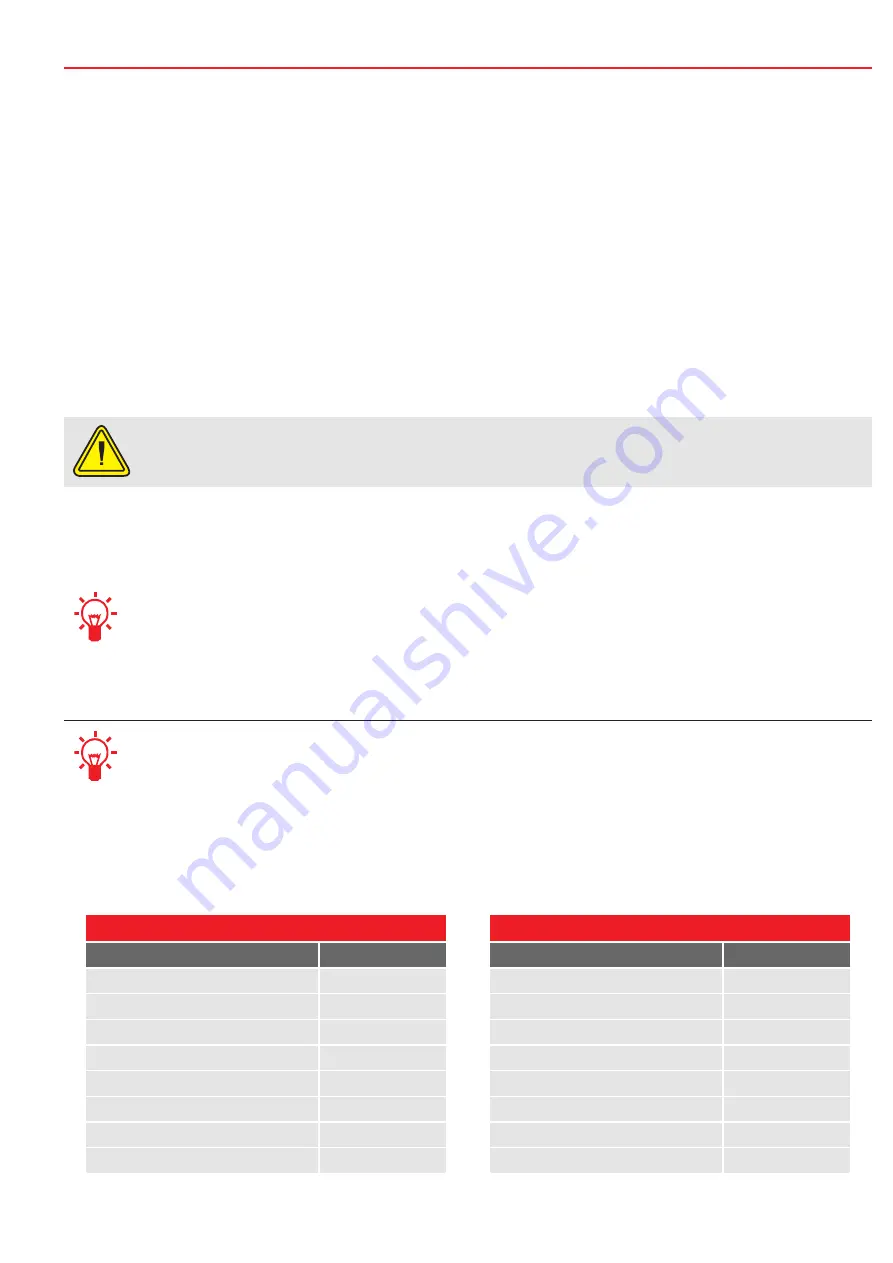

Check to see if the time corresponds to the indications in the table below:

- if the time is longer, increase the dilution

- if the time is shorter, add more paint

BUILDING PAINT

INDUSTRIAL PAINT

PRODUCTS

TIME

PRODUCTS

TIME

Oil paint

25 to 30 sec.

Hammered finish

30 to 50 sec.

Vinyl paint

30 to 35 sec.

Anti-rust

25 to 33 sec.

Acrylic paint

30 to 35 sec.

Lacquer, polyurethane

25 to 30 sec.

Pliolite

35 to 40 sec.

Lacquer, synthetic

22 to 27 sec.

Lacquer, brilliant, satin

25 to 27 sec.

Varnish, synthetic

20 to 22 sec.

Mat ceiling paint

25 to 30 sec.

Cellulosic

18 to 22 sec.

Anti-rust

25 to 33 sec.

Chromate and Wash-primer

18 to 22 sec.

Impression

20 to 25 sec.

Metallised

18 to 20 sec.

If the movement is too rapid, the risk of a paint lack will be important. If, otherwise, the

movement is too slow, bleeding may occur.