User manual - Eole T5 + HV460

202005-418-ENG

P12

4. USE OF THE MACHINE (continued)

4.3. SPRAY SETTING

To increase or decrease the product flow-rate, use the wheel (E) at the back of the spray-gun:

- screw to decrease the flow-rate

- unscrew to increase the flow-rate

To increase or decrease the jet width, use the ring (A):

- tighten to obtain a wider jet

- unscrew to obtain a more narrow jet

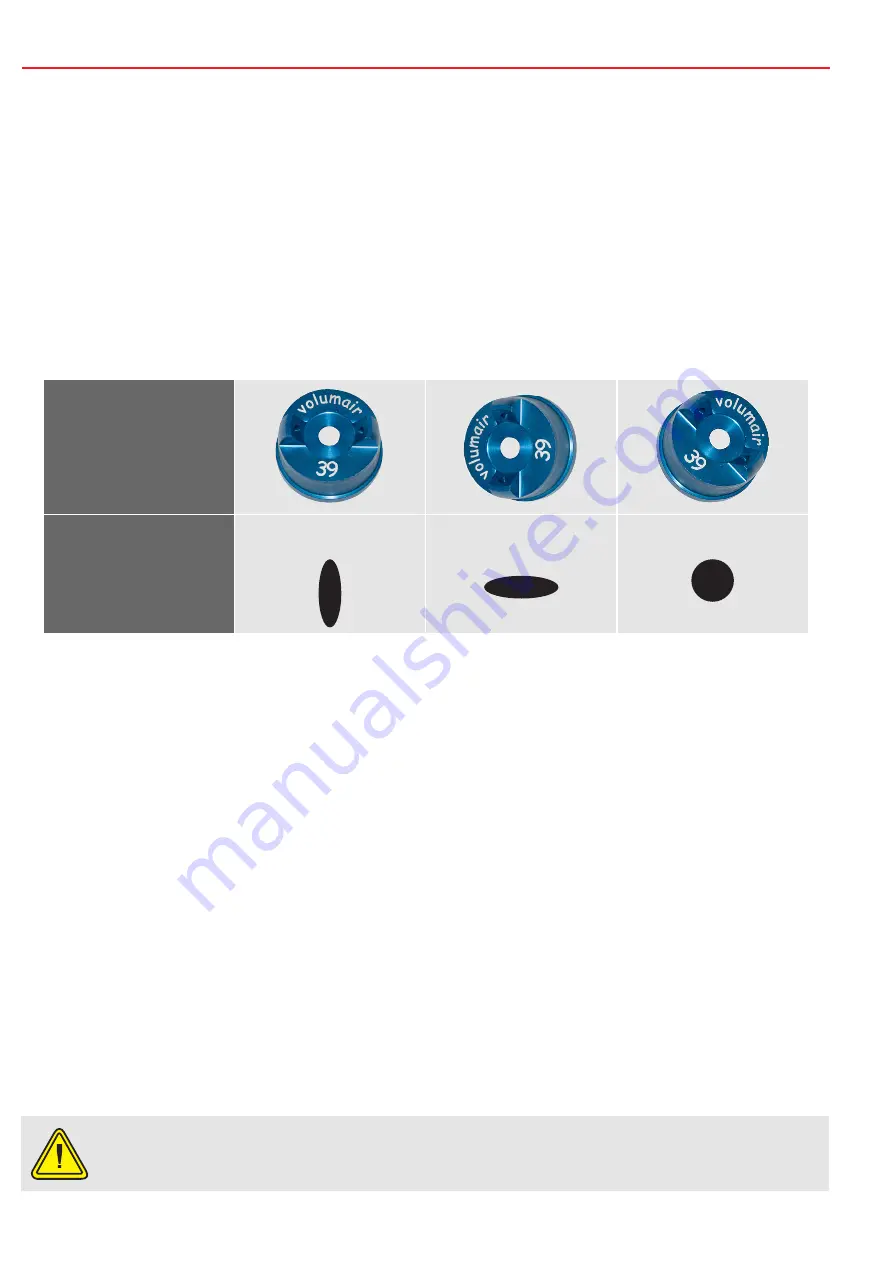

To obtain differents jets, direct the diffuser head as indicated below:

Head position

Spray render

Vertical flat spray

Horizontal flat spray

Round spray

4.4. SETTING UP OF THE EXTENSION POLE

• The extension pole takes the place of the diffuser head and the jet nozzle.

• Dismantle the ring (A).

• Dismantle the jet nozzle (F2).

• Mount the 1,5 mm needle.

•

Be sure the joint is well placed.

•

Mount the extension pole with the ring (A).

• Block the ring.

4.5. CHANGE OF THE ATOMIZATION KIT

• Remove the ring (A) and the diffuser head (F1).

•

Unscrew the setting wheel (E) and remove the spring.

• Press the trigger, the needle (F3) comes out easily from its housing.

•

Unscrew the jet nozzle using the key delivered with the spray-gun.

•

Reassemble the new nozzle jet and screw properly to avoid leaks.

•

Reassemble the spray-gun in the reverse order of the disassembly, with the new diffuser head.

Changing of the atomization kit, verify that the jet nozzle and the needle have the same

diameter.