13

On the TAMD60 engines, small quantities required for

topping-up can be added to the expansion tank, but other-

wise coolant should always be filled directly into the heat

exchanger through the hole for the hexagon plug, until the

engine is completely full and vented. Then close the ven-

ting cock at the turbo and screw the hexagon plug on the

heat exchanger. Thereafter, fill the expansion tank at the

side of the engine (1, fig. 11) with approx. 3 litres (0.66 Imp.

galls = 0.80 US galls) and replace the cap.

1.

If the engine is connected to a cabin heater, this must

also be vented before the cap on the expansion tank or

the plug on the heat exchanger are fitted. Otherwise

the engine may be damaged due to insufficient

cooling.

Finally, fill the separate expansion tank, if fitted, to

slightly above the MIN. level.

If the engine should run abnormally hot, carefully

vent the cooling system and top up with water.

2.

Lubricating oil level, engine. Check that the level is

between the marks on the dipstick. It must never be

permitted to fall below the lower mark.

(Check that the cock under the oil scavenging pump,

on the 70C-engine, is closed, see page 24.)

3.

Oil level, reverse gear. The level should reach the

mark (alternatively, it should lie between the two

marks) on the dipstick. Repeat the check for Twin Disc

reverse gears whilst idling with the control in the neu-

tral position, since this indicates the true level for this

type of reverse gear.

The oil level in the Borg Warner and SCG reverse

gears should be checked when the engine is not

running. The oil level will lie above the ”max.” mark

when the engine has been stationary long enough for

the oil to run down from the cooler and passages. To

obtain a true level reading the check should be made

immediately after the engine has been stopped.

4.

Check that the seawater cocks on the engine are

closed. See the figures on page 18.

5.

Open the bottom valve and the trickle-feed cock to the

bilge pump, if fitted. (Fig. 18).

6.

Fuel. Check that there is sufficient fuel in the tanks and

open the fuel cocks.

7.

Switch on the master switches. They should be on

when the engine is running.

NOTE! Switching off and on must never be carried out

while the engine is running, since this can damage the

charging regulator.

Fig. 13. Vent the cooling system. (The picture shows a 70C

engine.)

Fig. 14. Oil level, all engines

(the picture shows a 70-type

engine).

Fig. 15. Check the oil level

in reverse gear BW and

V-drive BW 10-05.

Fig. 16. Check the oil level

in the reverse gear TD.

Fig. 17. Check the oil level in

reverse gear SCG.

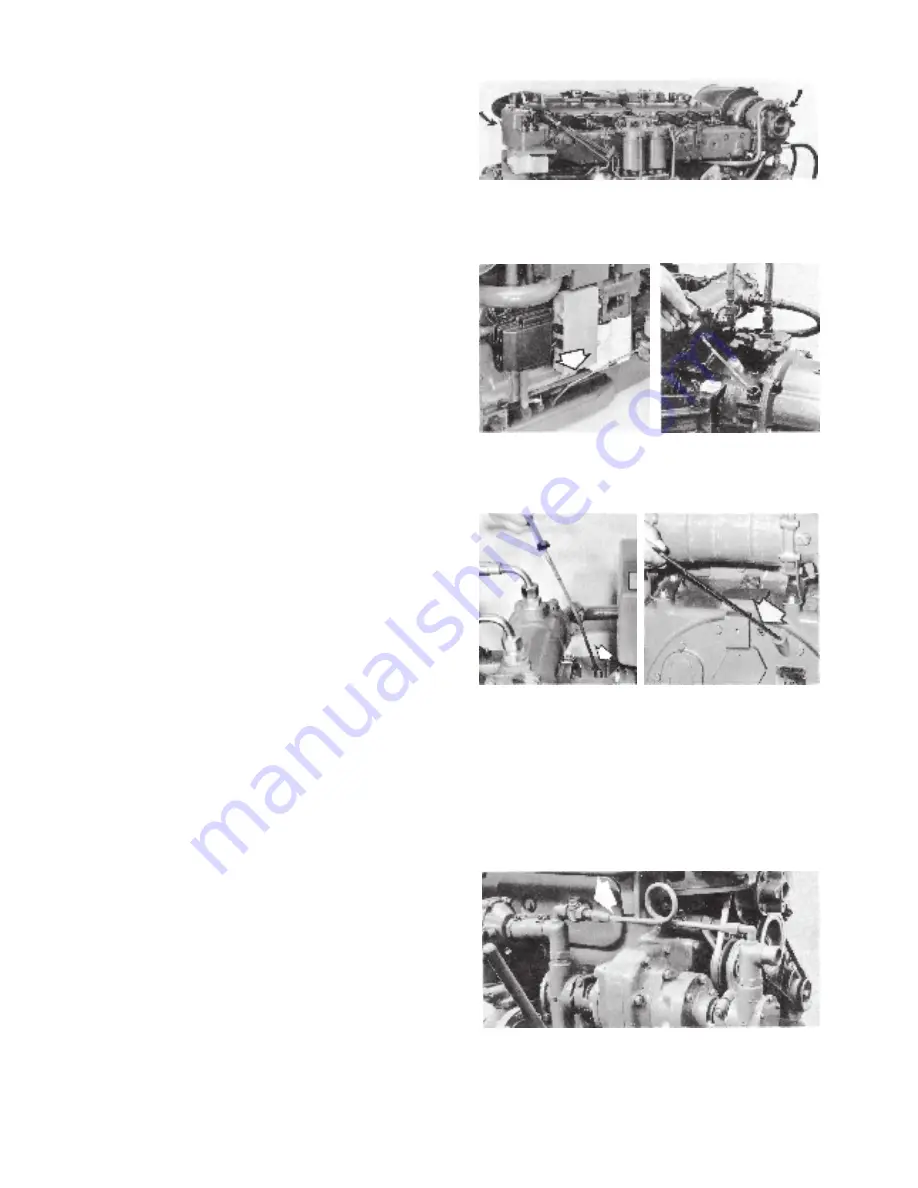

Fig. 18. Cock on trickle-feed line to bilge pump, if fitted. The

scribed line should be in line with the pipe when the cock is

open.