45

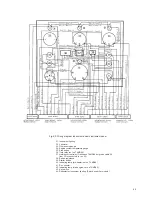

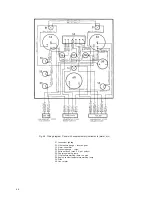

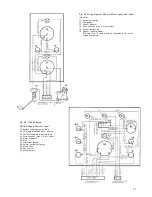

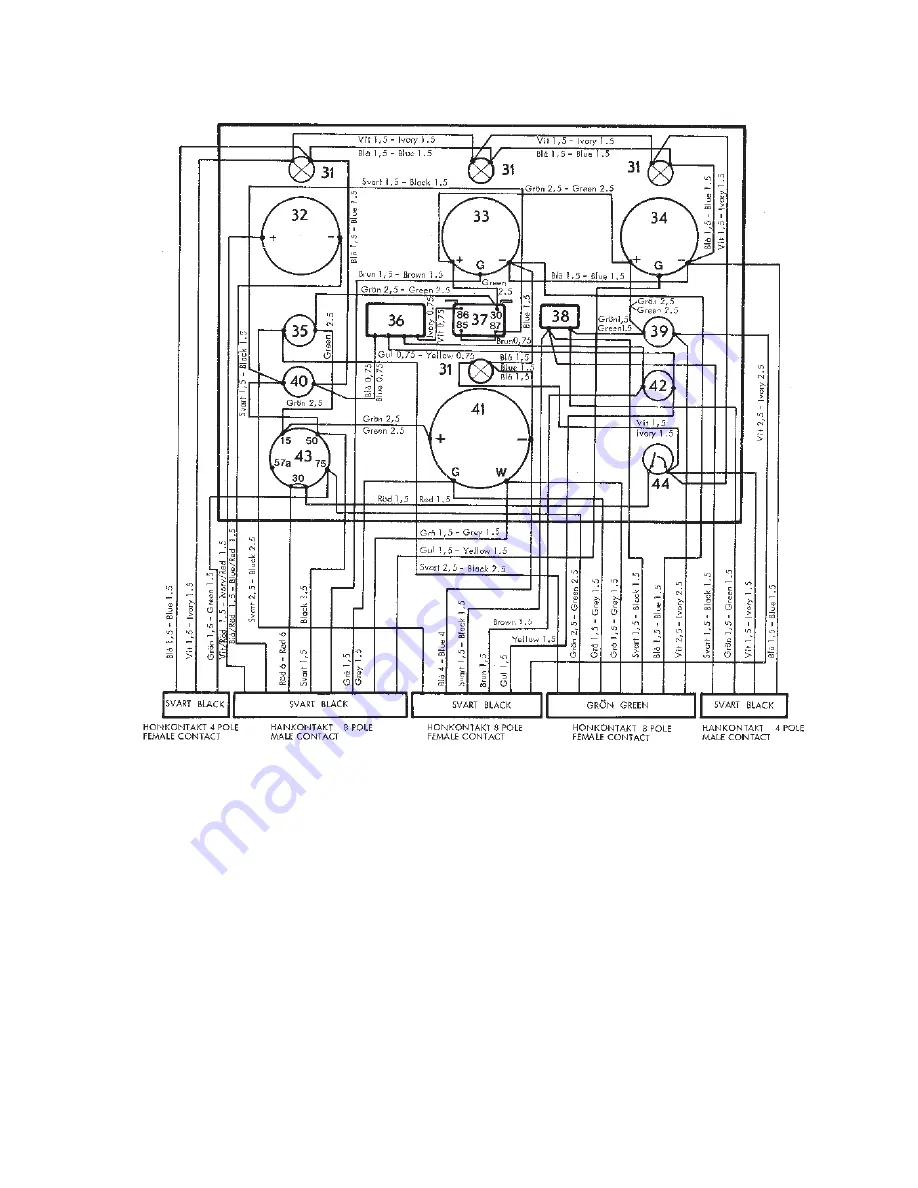

Fig. K3. Wiring diagram. Instruments, basic instrument panel

31. Instrument lighting

32. Voltmeter

33. Oil pressure gauge

34. Engine coolant temperature gauge

35. Stop button

36. Time relay (not on TAMD60)

37. Holding current relay (Omitted on TAMD60 but green cable 2.5

from 35 is connected to + on 33)

38. Series resistance

39. Starter button

40. Indicating lamp (pre-heater, not on TAMD60)

41. Rev counter

42. Indicating lamp (start engine, not on TAMD60)

43. Key switch

44. Rheostat for instrument lighting. (Switch on earlier models.)