Working mode

Local mode

In Local Mode the engine can only be started from the

main panel. External start/stop commands are

ignored.

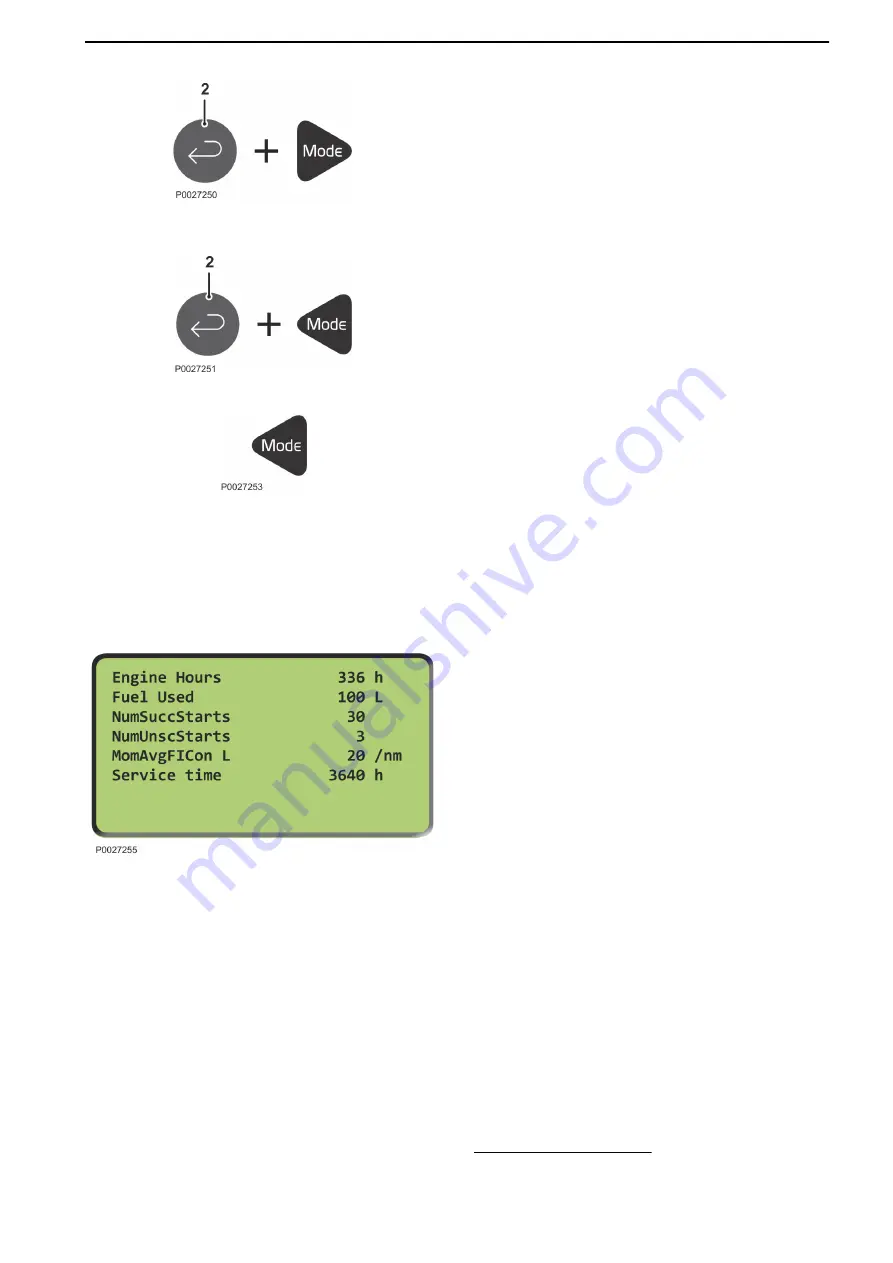

The mode is activated by pressing Enter (

2

) and the

right Mode button.

Exit mode by pressing Enter (

2

) and the left Mode

button.

Operations mode (AUX/PRP/EME/HBR)

In operations mode (AUX/PRP/EME/HBR) the engine

is ready for start when the status shows "Ready".

Off mode (OFF)

The engine cannot be started in OFF mode. All relay

output signals are temporarily disconnected and the

status is changed to “Not Ready”.

Activate OFF mode by pressing the left Mode button.

NOTICE!

The engine cannot be started; if the engine

is running it will be shut down when OFF mode is

activated.

Activate OFF mode by repeatedly pressing the left

Mode button until "off" is shown in the display's top left

corner.

Statistics

In the main menu, press the up button three times.

1 Operation hours

2 Total quantity of fuel used

3 Number of successful starts

4 Number of unsuccessful starts

5 Momentary average fuel consumption

(1)

6 Service time (hours until next service)

Statistical values can be adjusted with PC software

(password protected); contact your Volvo Penta

dealer.

1. Not standard; Comap InternetBridge hardware and adaptation of

software required.

Instruments and Controls

47711740 05-2019 © AB VOLVO PENTA

25

Summary of Contents for D16

Page 1: ...Operator s manual D16 genset ...

Page 86: ......

Page 88: ......

Page 90: ...AB Volvo Penta SE 405 08 Göteborg Sweden www volvopenta com 47711740 English 05 2019 ...