81

Maintenance: Propellers

4

1

2

3

5

6

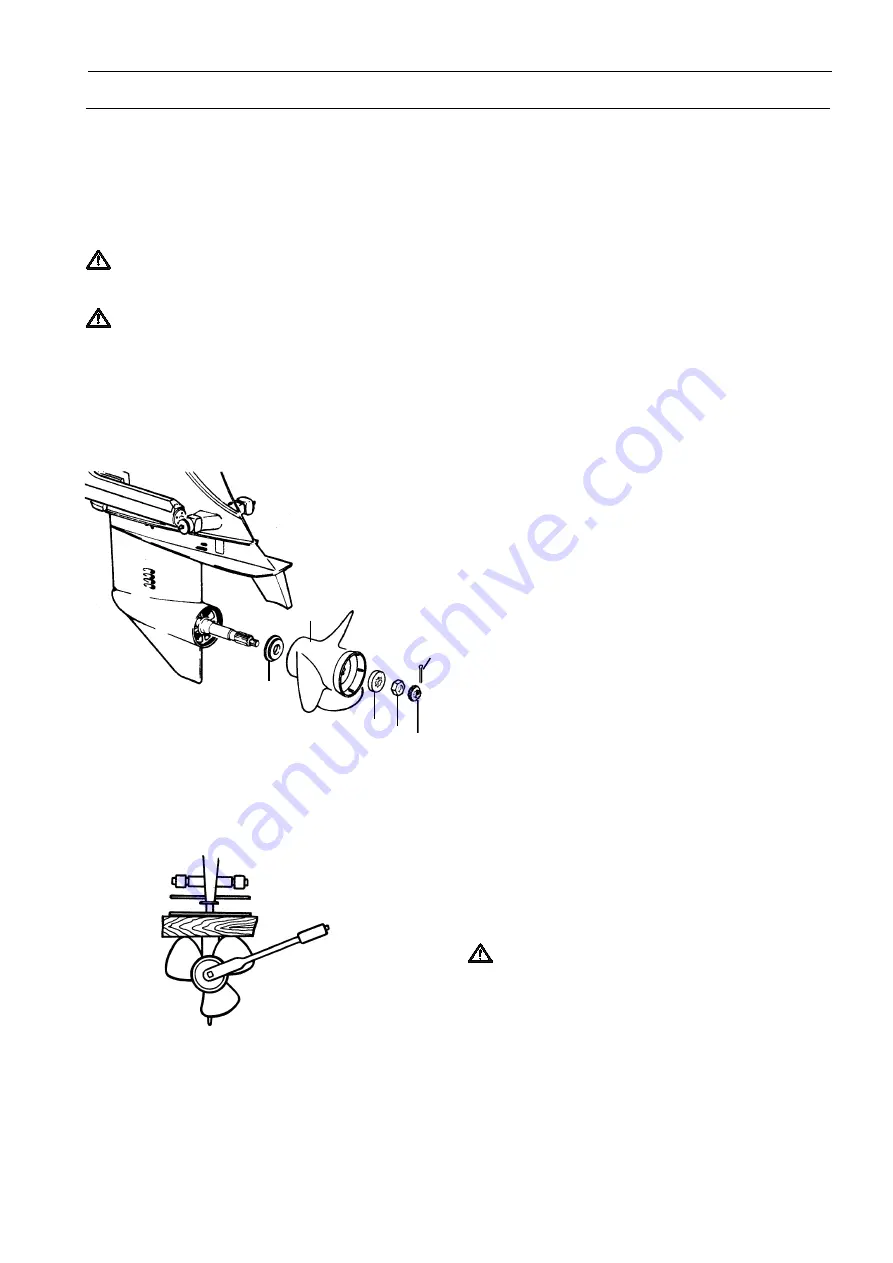

Removing and installing

The propeller shaft should be smeared with a water re-

sistant grease once a year.

1.

Set the control lever in the neutral position. Re-

move the split pin (1) and the locking tab washer (2).

2.

Put a wooden block between the propeller blade

and the cavitation plate.

3.

Remove the nut (3), spacer (4), propeller (5) and

the bushing (6).

4.

Grease the propeller shaft using water repellant

grease.

5.

Install the bushing (6) with the inner cone turned

toward the propeller shaft cone.

6.

Install the propeller (5). Press the propeller against

the bushing until the spline edges can be seen and

install the spacer (4) on the splines.

7.

Put a wooden block between one propeller blade

and the cavitation plate. Install the nut (3) and

tighten using a torque of 96-108 Nm.

8.

Install the locking tab washer (2) so the split pin

can be inserted in the hole on the shaft. Install

split pin (1).

IMPORTANT!

Always use a new split pin, do not

reuse the old one.

Propellers

For best performance and fuel economy the engine speed should be within the maximum RPM range, please refer

to

“

Operation; Cruising speed

”

. If the engine speed at maximum RPM falls outside the max. RPM range then the

propeller should be changed.

Ask your Volvo Penta dealership for advice if you wish to change to a propeller with another pitch or diameter.

For twin installations one propeller must be right rotating and the other left rotating. Both should have the same

pitch and diameter.

WARNING!

Make it impossible to start the engine when working on the propellers. Take the starter key out

of the starter switch.

IMPORTANT!

Damaged propellers should be replaced immediately. Operating the boat with a damaged pro-

peller should be undertaken with extreme care and only at reduced engine speeds.

Summary of Contents for D3-110i

Page 1: ...OPERATOR SMANUAL D3 130A D3 160A D3 190A D3 110i D3 130i D3 160i D3 190i ...

Page 103: ......

Page 104: ...7745859 English 12 2005 ...