49

Maintenance: Fuel System

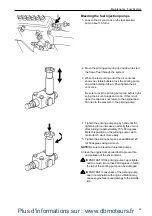

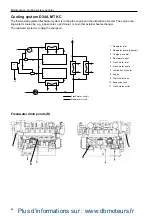

Bleeding the fuel injection pumps

1. Loosen the air vent cock on the fuel injection

pump about 1.5 turns.

2. Move the priming pump cap up and down to start

the flow of fuel through the system.

3. When the fuel coming out of the air vent cock

shows no visible bubbles, lock the priming pump

cap while holding it down. Then tighten the air

vent cock.

Be sure to lock the priming pump cap before tight-

ening the air vent plugs and cock. If this is not

done the cap does not return to the original posi-

tion due to the pressure in the priming pump.

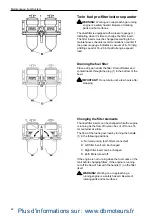

4. Tighten the priming pump cap by hand until the

tightening force increases, normally this occurs

after turning it approximately 70 to 90 degrees.

Mark this position on the priming pump cap to

make item 5 work more easily.

5. Tighten the priming pump cap an additional 120

to150 degrees using a wrench.

NOTE! Be sure to bleed both injection pumps.

6.Clean the engine from spoiled fuel to prevent fire

and pollution of the environment.

IMPORTANT! If the priming pump cap is tighte-

ned too much (more than 240 degrees in total),

the top of the priming pump can be damaged.

IMPORTANT! Looseness of the priming pump

cap in combination with engine vibration may

cause engine failure and damage to the installa-

tion.

Plus d'informations sur : www.dbmoteurs.fr