53

Maintenance: Fuel System

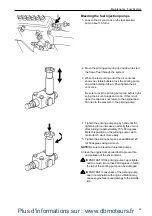

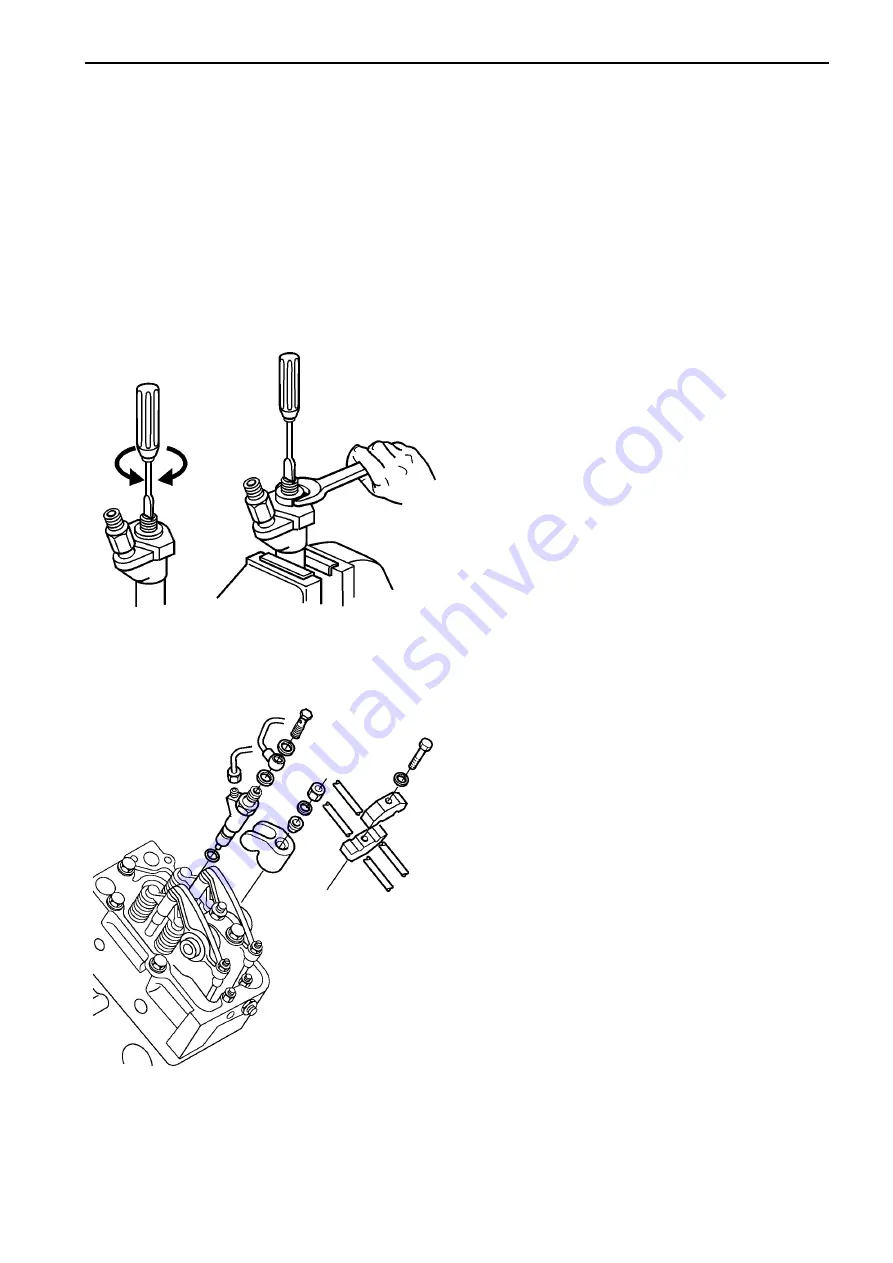

Adjusting the fuel injection pressure

1. To adjust injection pressure, remove the cap nut

from the nozzle holder, and then turn the adjus-

ting screw. To increase the injection pressure,

tighten the screw. To decrease the injection pres-

sure, loosen the screw.

2. When the pressure meets the standard value,

tighten the cap nut to 39 - 49 Nm (4 - 5 kpm)

[29 - 36 lbf.ft].

3. Tighten the set screw to 15 - 20 Nm

(1.5 - 2 kpm) [11 - 15 lbf.ft].

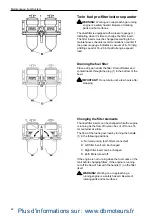

Fuel injection nozzle installation

1. Attach a nozzle gasket to the fuel injector nozzle.

2. Insert the fuel injector into the cylinder head.

3. Install the nozzle gland and tighten the nut to 78

Nm (8.0 kpm) [58 lbf].

Use new sealing washers when securing the fuel

injection pipe and fuel return pipe.

4. Tighten the fuel return hollow screw to 15 - 20 Nm

(1.5 - 2 kpm) [11 - 15 lbf.ft].

5. Before mounting the rocker cover, operate the

engine at approx. 700 rpm and check for fuel

leaks. Install the rocker cover.

Fuel injection nozzle spray pattern

Check spray conditions when checking fuel injection

pressure. Good spray conditions are as follows:

·

Fuel is injected from all nozzle holes.

·

The fuel is sprayed in a conical shape.

·

No big particles but fine ones.

·

No oil drip is left after injection.

If the nozzle fails to spray fuel properly, replace with a

new one.

NOTE! Fuel injection pressure and nozzle spray pat-

tern check intervals may be extended in steps of 250

hours if they are ok at 1000 hrs.

Plus d'informations sur : www.dbmoteurs.fr