51

Crankshaft assembly

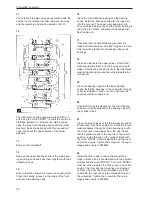

10

Check the mounting screws for wear and deforma-

tion and replace them if required. Lightly lubricate

the threads with engine oil. Install the screws and

washers and tighten the screws in stages and even-

ly to 112 Nm.

11

Check that the crankshaft can be freely turned. If

the thrust washers have been removed and rein-

stalled, check crankshaft axial clearance, operation

14A-03.

12

Install the oil screen and extractor pipe if required,

operation 18A-04.

13

Install the oil pan, operation 18A-03 and fill it to the

correct level with approved engine oil.

Crankshaft, replacement

(14A-08)

1

Drain the engine oil and the engine coolant system.

2

Remove the oil pan, operation 18A-03. Remove the

oil screen and extractor pipe 18A-04.

3

Remove the crankshaft pulley, operation 14A-01.

Remove the water pump pulley.

4

Remove the cap of the timing cover, operation 15A-

01.

5

Remove the flywheel and flywheel cover, section

21.

6

Turn the crankshaft until the pistons are at the

same height in the cylinder bores.

7

Temporarily mark the timing belt and the appropri-

ate teeth on the crankshaft pulley, camshaft pulley

and the injection pump pulley. This is to ensure

that the belt can be reinstalled in the correct posi-

tion.

8

Remove the timing belt, pulleys and timing cover,

section 15.

9

Remove the oil pump, operation 18A-06.

10

Measure the crankshaft axial clearance to deter-

mine if new thrust washers are required.

Main bearings, inspection

(14A-07)

Check the bearings for wear and damage. If a bear-

ing is worn or damaged, replace both the bearing

shells and check the condition of the other bearings.

Summary of Contents for MD22

Page 1: ...Engine repair MD22 TMD22 TAMD22 Workshop Manual 2 0 A ...

Page 2: ......

Page 129: ...127 Notes ...

Page 130: ...128 Notes ...

Page 132: ...7738684 5 English 04 1999 ...