78

Lubrication system

Oil screen and suction pipe,

replacement

(18A-04)

The oil screen is an integrated part of the suction

pipe. No regular service is required, but clean the

oil screen when it is dismantled.

1

Remove the oil pan, operation 18A-03.

2

Remove the screw securing the bracket to the main

bearing cap.

3

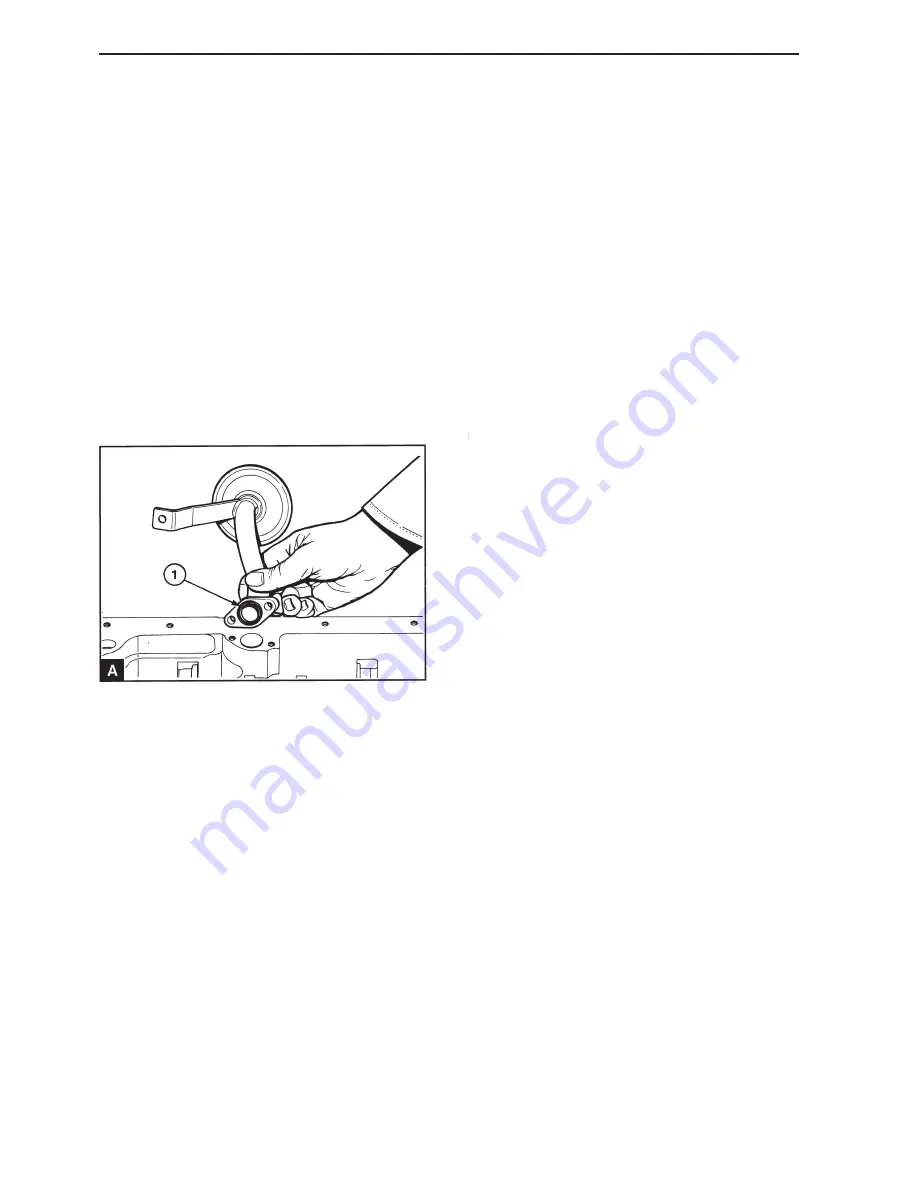

Remove the screws at the suction pipe flange and

remove the suction pipe and screen. Remove the

O-ring (A1). Clean the flange surface on the cylin-

der block and the suction pipe.

4

Install the suction pipe bracket loosely to the cor-

rect main bearing cap. Install the suction pipe to the

oil pump with a new O ring. Tighten the screws.

Tighten the mounting screws for the suction pipe

bracket, ensure that the suction pipe is not subject-

ed to tension.

5

Install the oil pan, operation 18A-03 and fill it to

”MAX” on the dipstick with an approved engine oil.

Oil screen and suction pipe,

inspection (18A-05)

1

Clean the unit in kerosene and dry it carefully.

2

Check the pipe, screen and welded joints for cracks

and other damage. Check that the mounting bracket

is well tightened.

3

If a damaged component cannot be welded correctly

the whole unit should be replaced.

Summary of Contents for MD22

Page 1: ...Engine repair MD22 TMD22 TAMD22 Workshop Manual 2 0 A ...

Page 2: ......

Page 129: ...127 Notes ...

Page 130: ...128 Notes ...

Page 132: ...7738684 5 English 04 1999 ...