89

Fuel injection system

Fuel injection pump, replace-

ment (19A-06)

Special tools: 885027, 885029, 885037

1

Disconnect the battery.

2

Position the piston in cylinder 1 at TDC in the com-

pression stroke, operation 17A-01 and install the

adjustment drifts 885037.

3

Remove the cap for the timing cover, the timing belt

and the fuel injection pump pulley, see section 15.

4

Disconnect the fuel injection pump engine speed

regulator and, if necessary, the stop control. Detach

the cable from the stop solenoid on the pump. Mark

the cables in a suitable way to facilitate reinstalla-

tion.

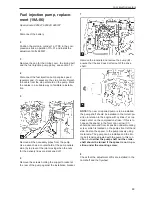

5

Remove all the necessary pipes from the pump.

Use a wrench as a counterhold at the pump outlets

side (A) to prevent the joint moving when the nuts

for the delivery lines are slackened off.

6

Remove the screws holding the support bracket at

the rear of the pump against the installation bracket.

7

Remove the locknuts and remove the pump (B) –

ensure that the key does not fall out of the drive

shaft.

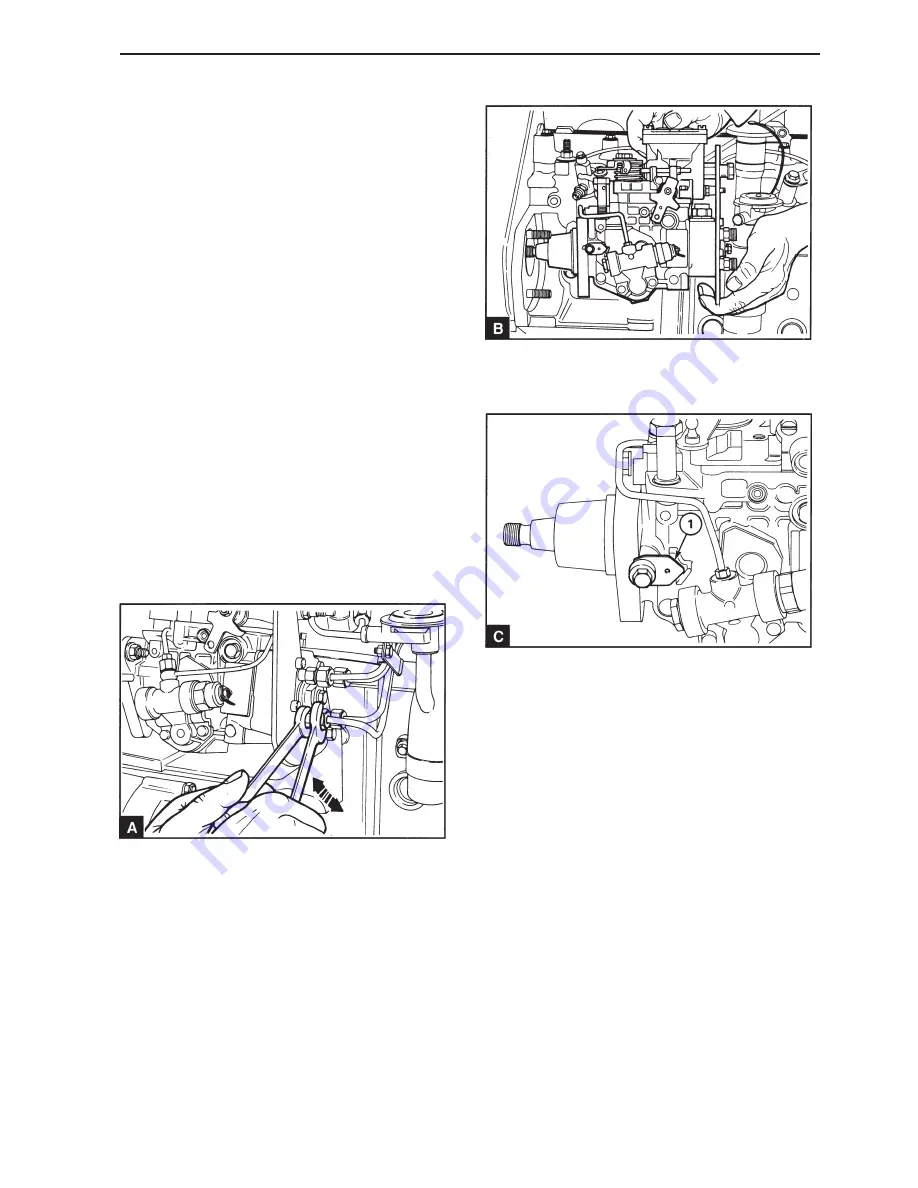

NOTE! If a new or repaired pump is to be installed,

the pump shaft should be installed in the correct po-

sition in relation to the engine with cylinder 1 at top

dead center on the compression stroke. If this is to

happen the spacer in the form of an arrow (C1)

should be removed from its position under mounting

screw, which is located on the pumps front left hand

side. Fasten the spacer to the pump loosely using

metal wire. The pump can be installed and the tim-

ing belt tension adjusted with the pump in this con-

dition, but neither the pump shaft nor the crank-

shaft should be turned if the spacer is not in po-

sition under the mounting screw.

8

Check that the adjustment drifts are installed in the

camshaft and the flywheel.

Summary of Contents for MD22

Page 1: ...Engine repair MD22 TMD22 TAMD22 Workshop Manual 2 0 A ...

Page 2: ......

Page 129: ...127 Notes ...

Page 130: ...128 Notes ...

Page 132: ...7738684 5 English 04 1999 ...