18

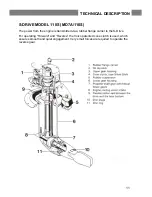

CHECKING AND REPLACING THE V-BELT

Check the belt carefully, both for wear

and cracks. Any sign of such and the belt

must be replaced. Loosen the alternator

mounting bolts so that the belt can be

removed. Clean the pulley grooves before

fitting the new belt. Tension the belt so

that it can only be depressed 5 mm

(3/16”) midway between the pulleys. After

a few hours running, recheck belt tension

and adjust if necessary.

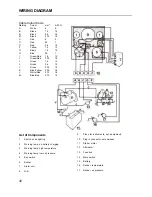

RETIGHTENING CYLINDER HEAD NUTS

Retighten each nut

with a torque wrench

before starting a new engine or an over-

hauled engine for the first time, and then

again after 20 hours of operation. The

valve clearance should always be

checked after the nuts have been

retightened. Sequence for tightening nuts

is shown in the figure opposite.

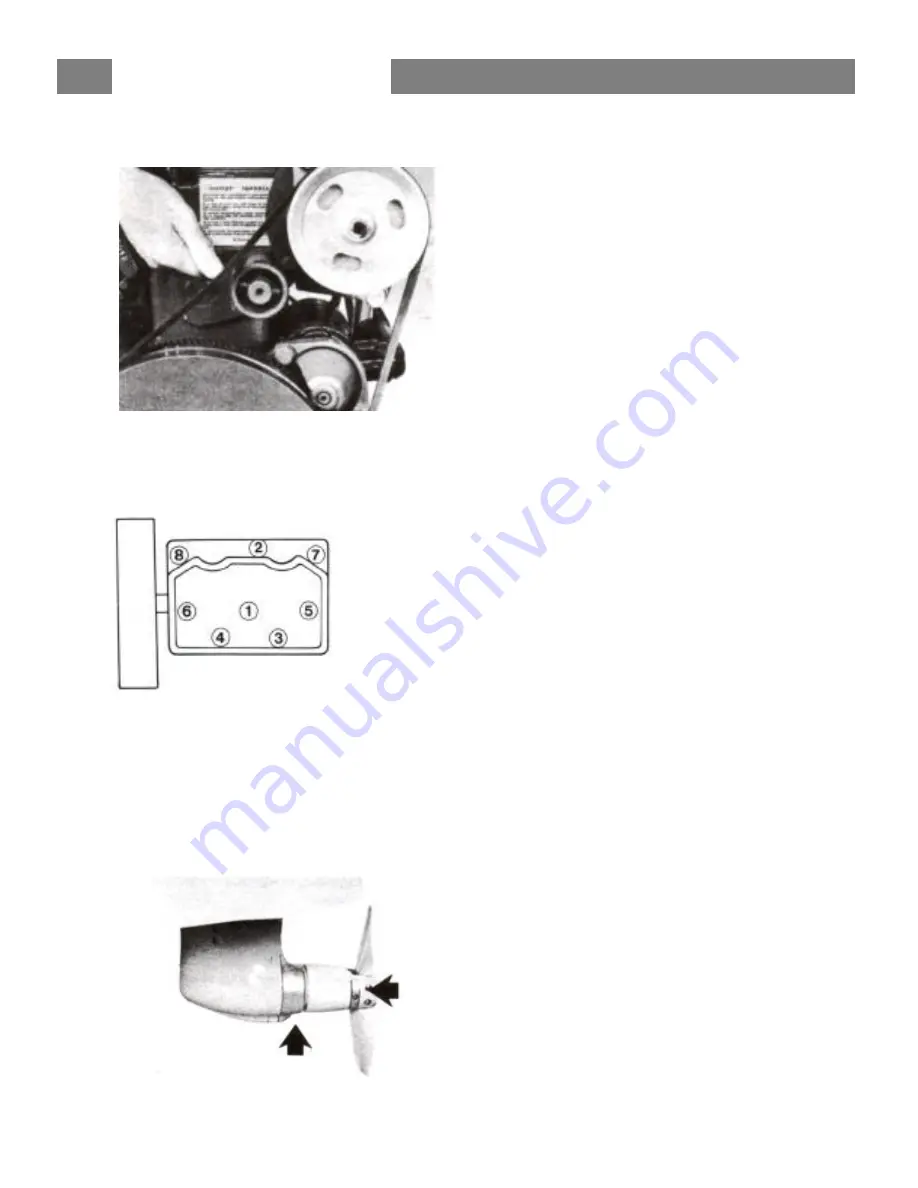

ZINC-ANODE, PROPELLER

(S-DRIVE 110S)

Replace the zinc-anode if it is eaten away

to more than 50%. Remove the propeller

and the spacer-ring with deflector and

remove the Allen-head screws, holding

the zinc anode. Clean the contact surface

on the S-Drive and install a new zinc-

anode. Be careful to obtain a good metal-

lic contact between the S-Drive and the

zinc-anode. Also replace the zinc-anodes

on the S-Drive when eaten away to more

than 50%. NOTE! Do not paint the zinc-

anodes.

Check to make certain that the propeller-

blades are folding easily, see “Inhibiting

Scheme), page 26, paragr 13.

CHECKS AND SERVICE