11

Presentation

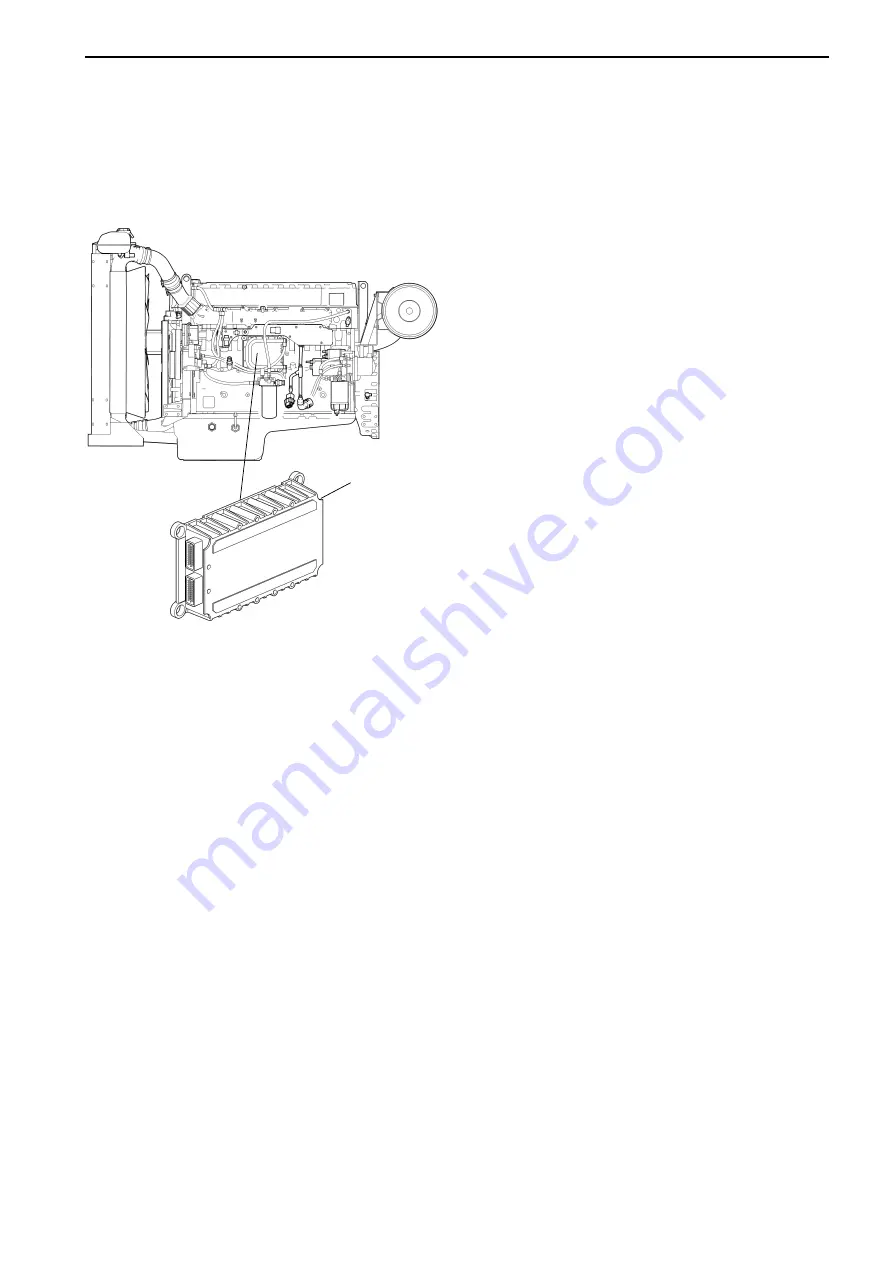

Control unit (1)

The EDC III system’s processor is located in the con-

trol unit, protected from moisture and vibrations.

The processor continually receives information regar-

ding:

–

rpm levels

–

intake boost pressure

–

intake temperature

–

coolant temperature

–

oil pressure

–

oil temperature

–

fuel alarm, includes both ”water in fuel” as well as

”fuel pressure”

–

coolant level

The information provides a precise overview of current

operational conditions making it possible for the pro-

cessor to do such things as determine the correct fuel

dosage and check on the engine’s condition.

Fuel management

The fuel needs of the engine are analyzed up to 100

times per second. Fuel injection quantity and timing

are controlled electronically via fuel valves in the unit

injectors.

This means that the engine always receives the cor-

rect amount of fuel under all operating conditions,

providing benefits including improved fuel economy

and minimized exhaust emissions.

Diagnostic function

The diagnostic system’s function is to detect and lo-

calize disturbances within the EDC III system, to pro-

tect the engine as well as to insure the ability to con-

trol the engine during serious disturbances.

If a disturbance is detected a diagnostic indicator in

the control panel will begin to blink. Pushing the dia-

gnosis button will provide the operator with an error

code to assist in locating the problem.

EDC III

EDC III stands for ”Electronic Diesel Control” and is an electronic system with CAN (Controller Area Network)

communication for diesel engine management. The system was developed by Volvo Penta and includes such pa-

rameters as fuel management and diagnostic functions.

1

Summary of Contents for TAD1240GE

Page 1: ...Generating set and industrial engines 12 liter EDC III OPERATOR SMANUAL ...

Page 69: ...Notes ...

Page 70: ...Notes ...

Page 75: ......

Page 76: ...7745138 English 12 2005 ...