Service procedures - intake and exhaust systems

Group 22

124

Charge air cooler, checking for

leakage, TAD-engines

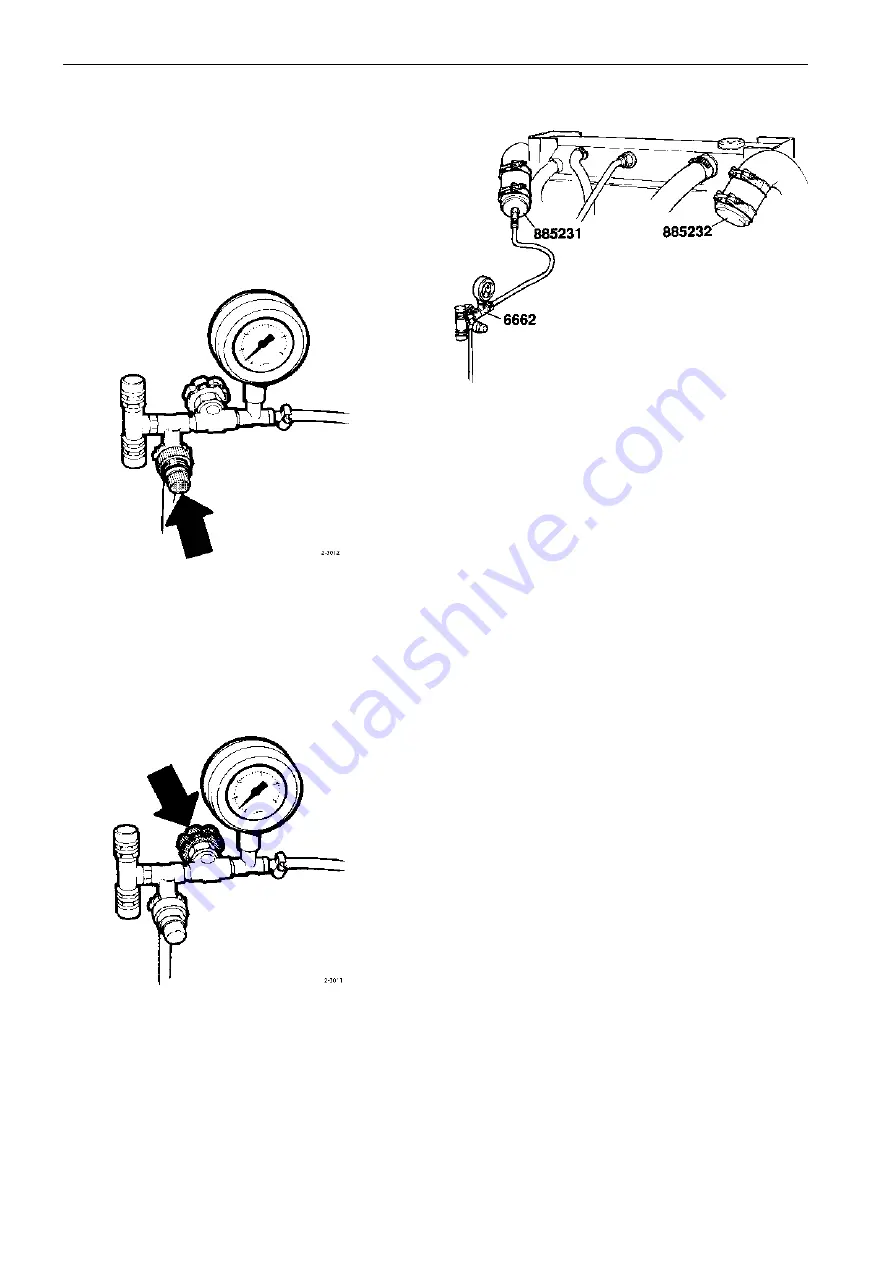

Special tools: 999 6662, 885231, 885232

Check the pressure tester before use.

1

Connect the pressure tester to the workshop air supply and

set the pressure gauge to 100 kPa (14.5 psi) with the reduc-

tion valve.

Note: To lock the reduction valve knob, move the lock ring

axially.

2

Shut off the valve. The pressure gauge dial pointer must not

drop during 2 minutes, otherwise the gauge cannot be relied

upon.

3

Disconnect the charge air hoses from the charge air cooler.

4

Fit connection tool 885231 and sealing tool 884232 together

with new hoses (if needed) on the charge air cooler. Un-

screw the pressure tester reduction valve.

Connect the pressure tester to the charge air cooler.

5

Open the shut-off valve knob and set the gauge to a pres-

sure of 70 kPa (10.2 psi) with the reduction valve.

6

Close the shut-off valve. During one minute pressure may

not drop more than 20 kPa (2.9 psi) otherwise the charge air

cooler cannot be approved.

7

In the event of leakage, repeat the check several times. Also

check the pressure tester hoses and connections.

8

Remove the testing equipment.

9

Connect the charge air hoses.

Summary of Contents for TAD1630G

Page 1: ...Workshop manual TAD1630G GE P V TAD1631G GE TID162AP TWD1620G GH TWD1630G GE P V TD164KAE ...

Page 2: ......

Page 18: ...Design and Function Group 21 16 Engine Design and Function ...

Page 80: ...Service procedures engine Group 21 78 Application of sealant to cylinder block ...

Page 162: ...160 ...

Page 164: ...7742302 English 10 2002 ...